Antibiosis and haze prevention mask

An anti-haze and mask technology, applied in protective clothing, clothing, clothing, etc., to achieve the effect of being easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

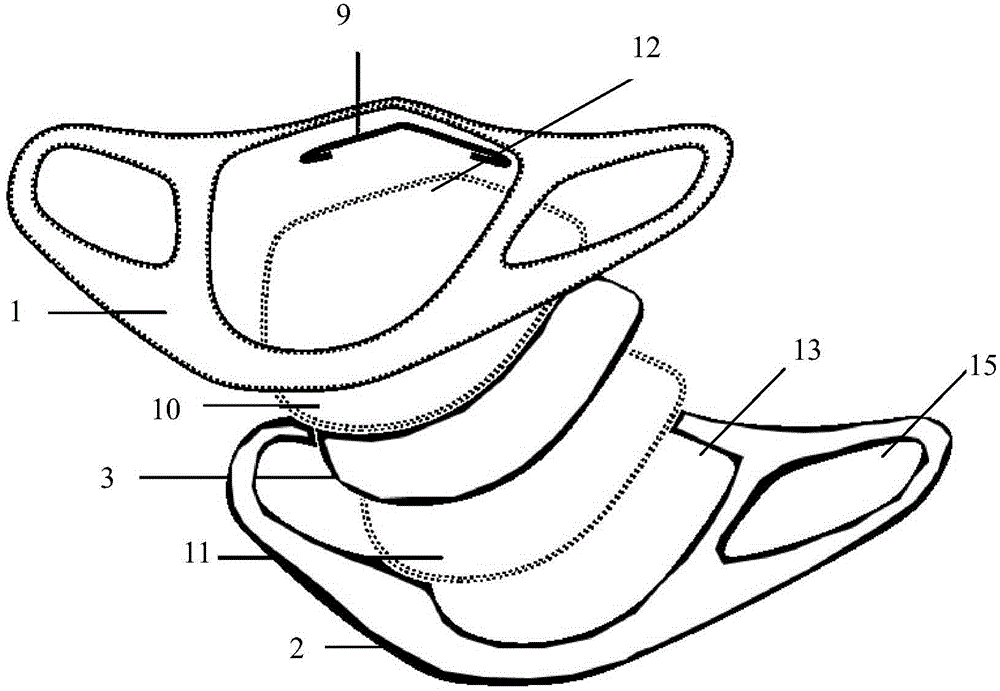

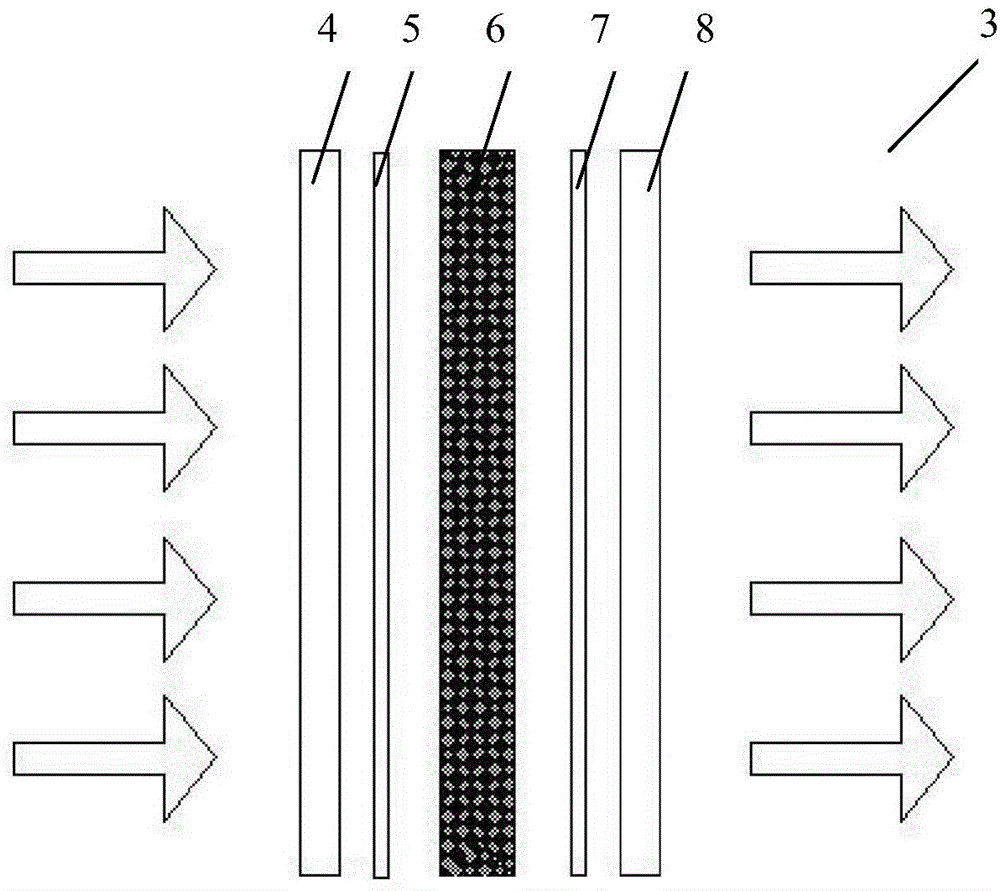

[0025] An antibacterial and anti-haze mask of the present invention comprises a surface layer 1 and a lining 2, an antibacterial and anti-haze functional layer 3 is arranged between the surface layer 1 and the lining 2, and the functional layer 3 is formed from From outside to inside, it is composed of the first fiber layer 4, the silver-loaded short fiber non-woven filter layer 5, the silver-loaded fiber silk filter layer 6, the high-efficiency filter layer 7 and the second fiber layer 8. The first fiber layer 4, The second fiber layer 8 is made of linen cloth or cotton linen cloth or full cotton cloth or blended cloth respectively, and described silver-loaded staple fiber spun non-woven fabric filter layer 5 is to be 20g / m by grammage 2 -40g / m 2 Polypropylene or polyester non-woven fabric, a layer of nano-silver is arranged on the surface of the non-woven fabric, the thickness of the silver-loaded fiber silk filter layer 6 is between 1.0-2.0mm, and the silver-loaded fiber T...

Embodiment 2

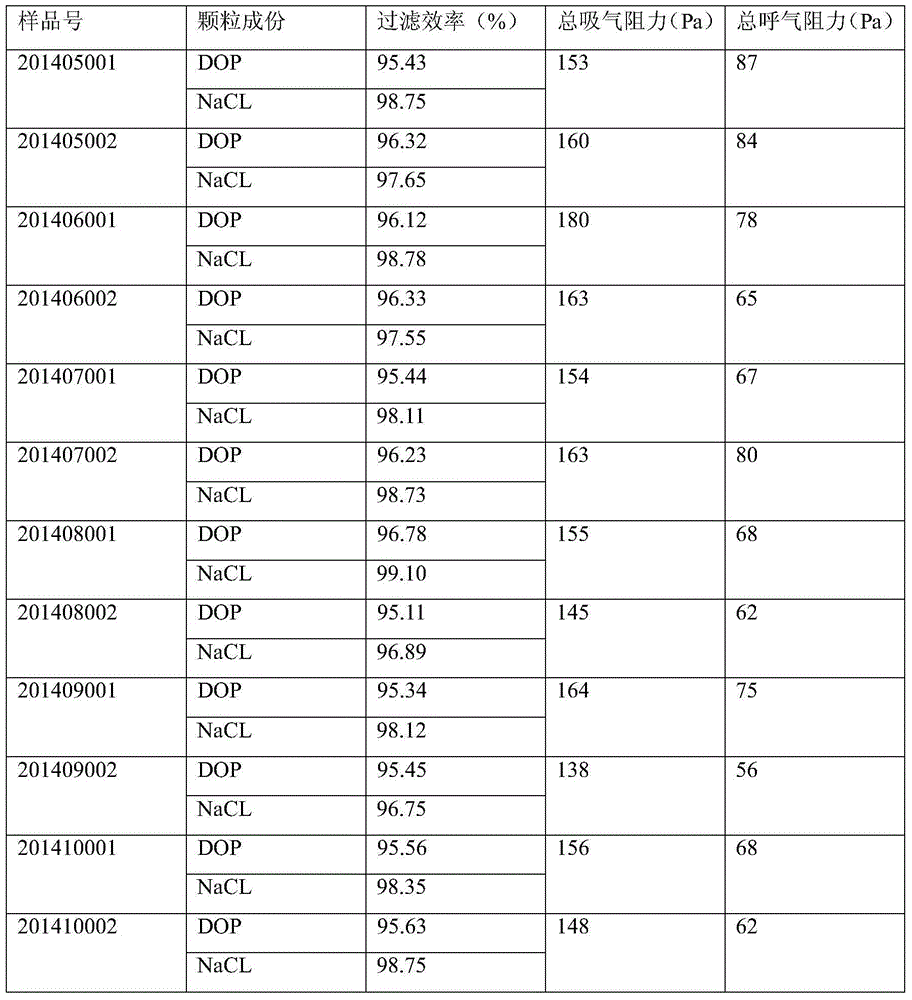

[0036] The measurement of filtration efficiency is carried out on GK-3016 filtration efficiency tester equipment, and the total inspiratory resistance and total expiratory resistance are carried out on ZR-1210 mask breathing resistance tester. The specific experimental test method is carried out in accordance with the requirements of the national GB2626-2006 (respiratory protective equipment self-priming filter type anti-particulate respirator).

[0037] Table 1 Filtration efficiency and resistance test.

[0038]

Embodiment 3

[0040] The sample number 201405001 mask was measured on the GK-3016 filter efficiency tester and the ZR-1210 mask breathing resistance tester respectively, and the first test parameters were recorded. Put the sample number 201405001 into a container with a little clean tap water and soak for about 15 minutes. Then gently scrub with hands for 2 or 3 minutes. Finally, rinse it with clean water and dry it in a drying oven. The temperature of the drying box equipment is 50°C , after drying, test the efficiency and breathing resistance on the above equipment in turn, and record the parameters measured for the second time. In other order, repeat the second experimental procedure. until the tenth test is completed.

[0041] Table 2 Cleaning times and efficiency test results

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com