Synthetic filter material, filter-paper-free metal-free synthetic filter element, manufacturing method of filter element, and filter

A technology of filter material and filter element, which is applied in the field of nylon skeleton synthetic filter element and its processing, to achieve the effects of prolonging the service life of engine oil, strong impact resistance, and optimizing maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

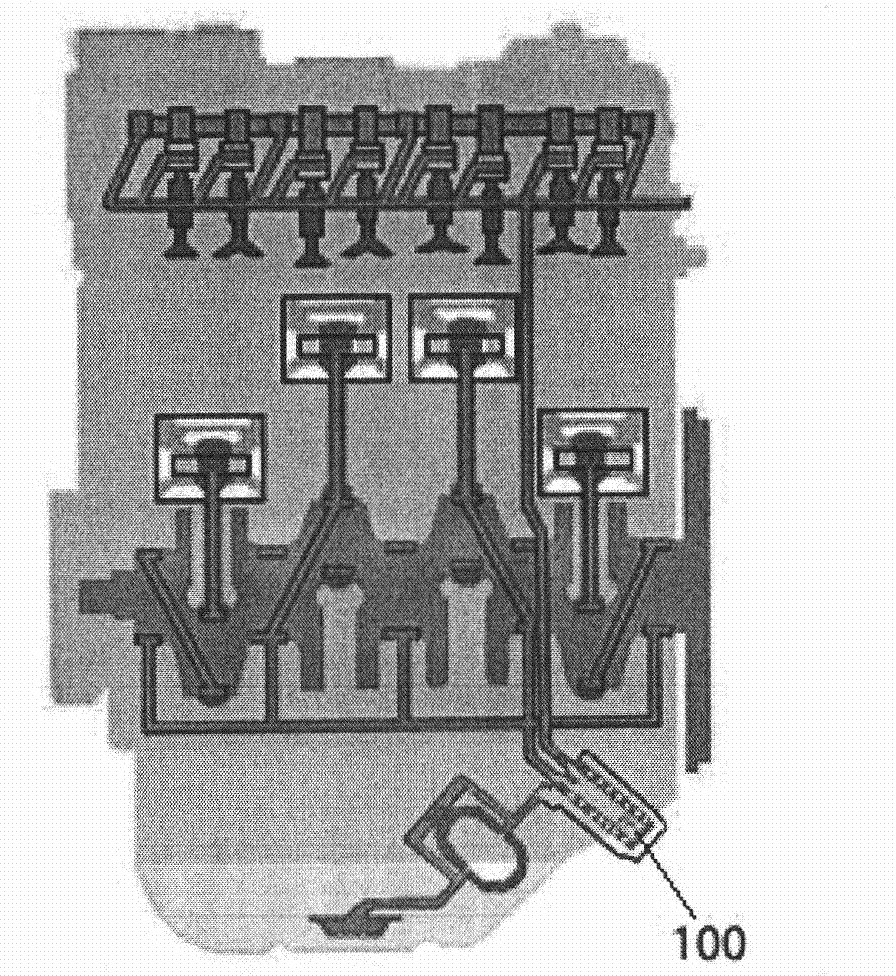

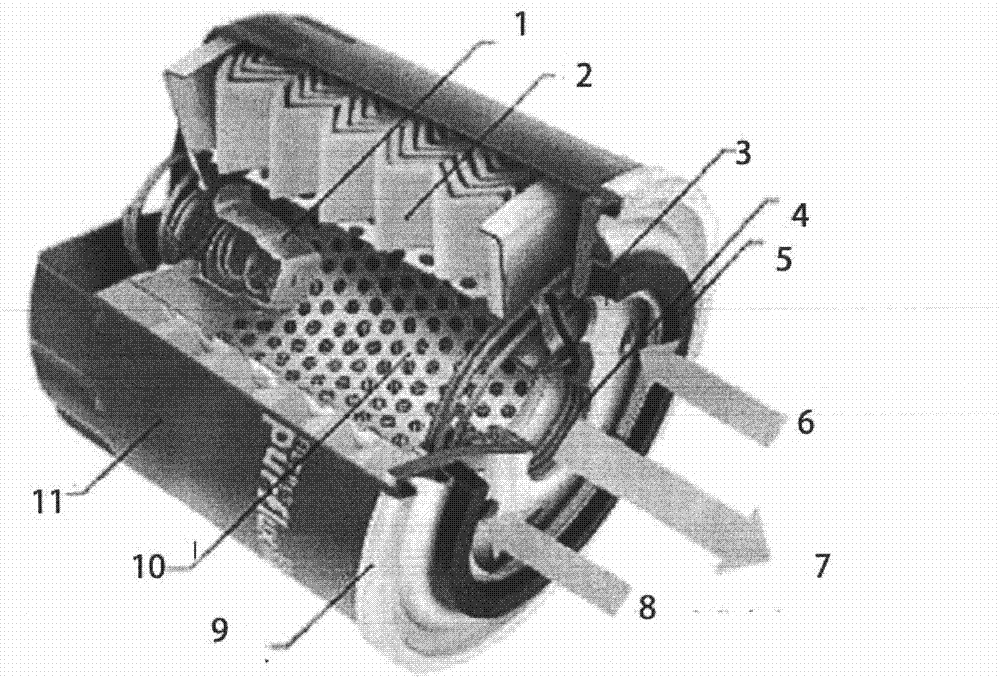

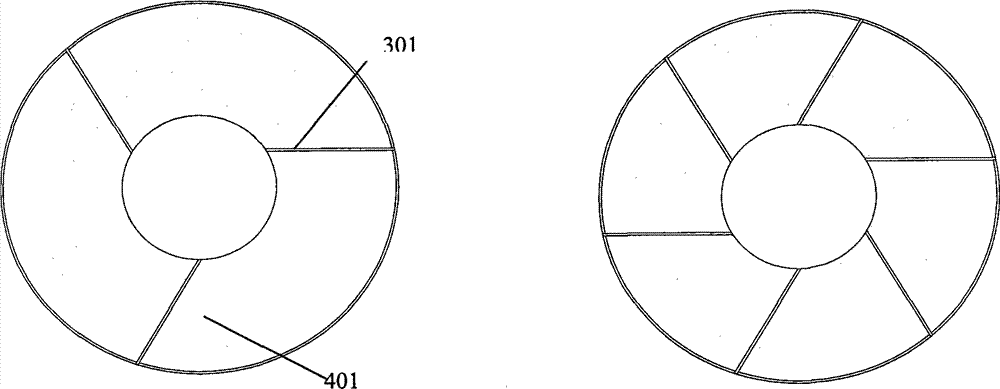

[0025] Such as Figure 3 to Figure 9 As shown, the filter core body of the present invention includes a core body skeleton and a core body module (401). The core frame includes an inner core frame, an outer frame, and upper and lower end covers (101a, 101b). The inner skeleton of the core includes a cylindrical central tube (201) and blades (301) formed of modified nylon materials. The cylindrical central tube (201) is sintered at high temperature and 3 to 8 vertical blades (301) are integrated into a core body. Skeleton, each blade forms a 30-degree angle with the cylindrical central tube and equally divides the circumference. The number of blades is determined according to the filter size of different models. For example, the filter suitable for the gasoline engine Santana model has 3 blades, and the JX1023 filter suitable for diesel engines has 6 blades, and it can also have 8 sets of blades. combination. A 40 μm fiber mat (211) can be attached to the outer wall of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com