Purification process, comprehensive utilization method and application of ganoderma lucidum spores powder

A technology of ganoderma spore powder and ganoderma spores, which is applied in the field of preparation technology of ganoderma lucidum spore powder, can solve the problems of ganoderma spore wall system evaluation, material basis, biological activity and mechanism of action unknown, so as to improve quality and added value, and achieve sustainable The effect of sustainable development and technological science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

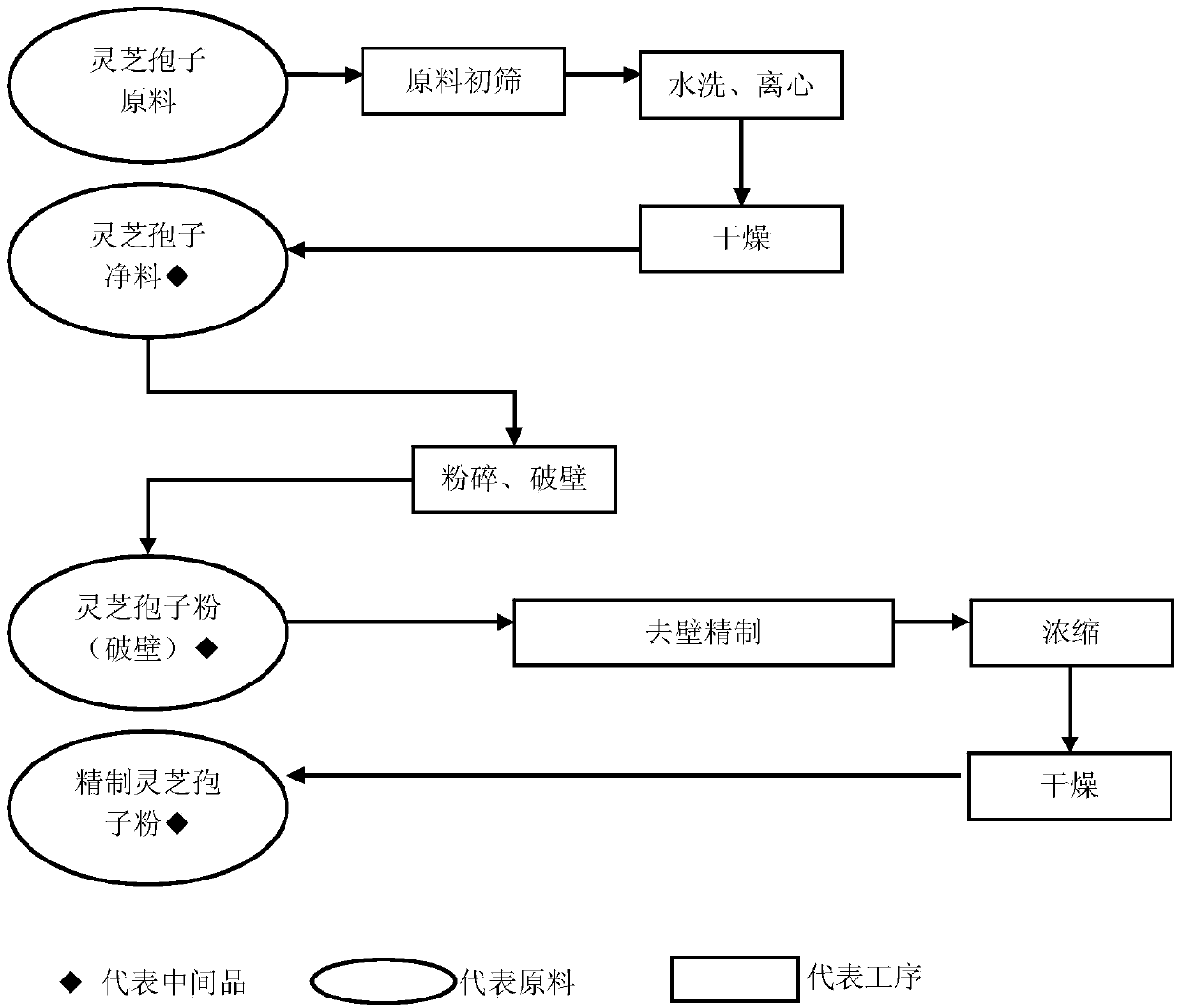

[0045] The refining technology of Ganoderma lucidum spore powder is attached figure 1 As shown, the specific steps are as follows:

[0046] (1) Weigh the ganoderma lucidum spore raw material and pass it through an 80-mesh sieve to remove larger gravel and sediment;

[0047] (2) Put 2000g of sieved spores into a mixing tank, add 16000g of distilled water, stir for 20 minutes and then let stand for 15 minutes. Fish out the shell spores and other floating impurities from the feeding port, and discharge the sludge and gravel that have sunk at the bottom of the mixing tank from the drain at the bottom of the mixing tank. Overflow the middle spore suspension into the iron tank, and pump it into the filter centrifuge to shake off the water;

[0048] (3) The wet spores after centrifugation are placed in a tray in a vacuum microwave dryer, spread evenly in thickness, and dried at low temperature. The thickness of the material is ≤4cm, the temperature is ≤60°C, dried to a water conte...

Embodiment 2

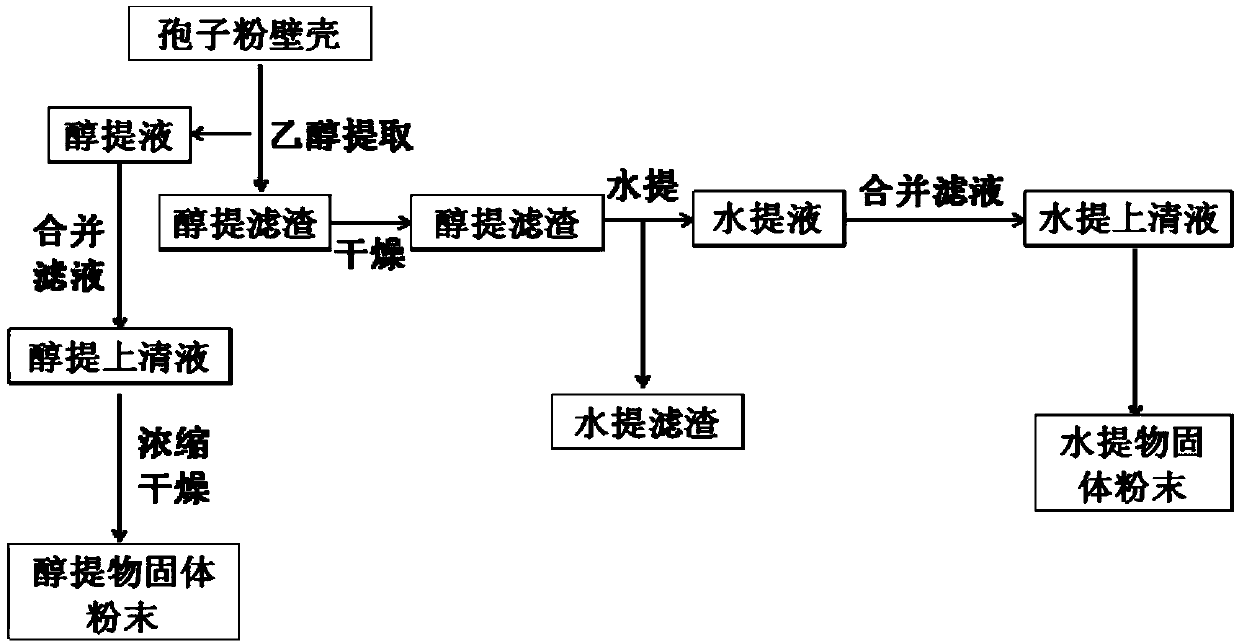

[0054] The comprehensive utilization method of Ganoderma lucidum spore powder shell as attached figure 2 As shown, it specifically includes the following steps:

[0055] (1) Take 1000 g of the spore powder wall shell obtained in step (5) of Example 1, and extract 3 times at 80° C. for 4 hours with 8000 g of a 70% ethanol solution by volume fraction. The extracts were combined, filtered to obtain filtrate A and filter residue A, the filtrate A was concentrated under reduced pressure to reclaim ethanol, and 60 g of solid powder of ethanol extract of shellfish was obtained by freeze-drying;

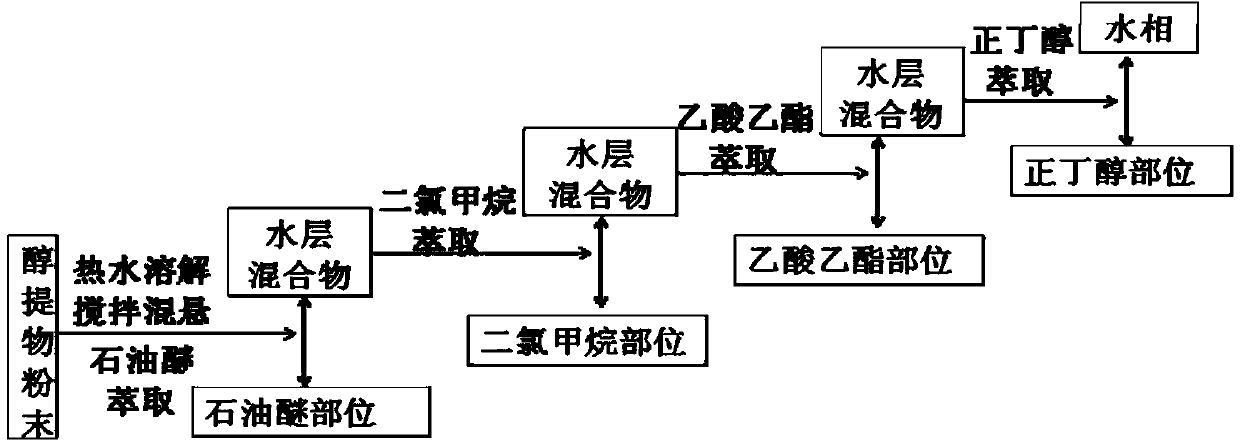

[0056] (2) Take 50g of the solid powder of the ethanol extract of the shell shell, add 150g of hot water at 70°C to soak for 30 minutes and stir thoroughly, then add 150g of petroleum ether to extract for 3 times, after extraction, combine all the petroleum ether layers, concentrate under reduced pressure, and freeze-dry 20 g of petroleum ether extract-like solids were obtained; the remain...

Embodiment 3

[0060] Content detection of active ingredients in refined Ganoderma lucidum spore powder and ordinary Ganoderma lucidum spore powder

[0061] Get the refined Ganoderma lucidum spore powder produced in Example 1, and get the common Ganoderma lucidum spore powder produced by conventional technology in addition, respectively adopt the phenol-sulfuric acid method, vanillin-glacial acetic acid-perchloric acid method to measure polysaccharide content and total triterpene content, with Glucose and oleanolic acid were used as controls, and the absorbance of the samples was measured by spectrophotometry at 490nm and 550nm, and the corresponding concentrations were calculated according to the standard curve. The results showed that the content of crude polysaccharides and total triterpenoids in the refined Ganoderma lucidum spore powder was significantly higher than that in the common Ganoderma lucidum spore powder (P<0.01), and the content increased by nearly 20 times. The results are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com