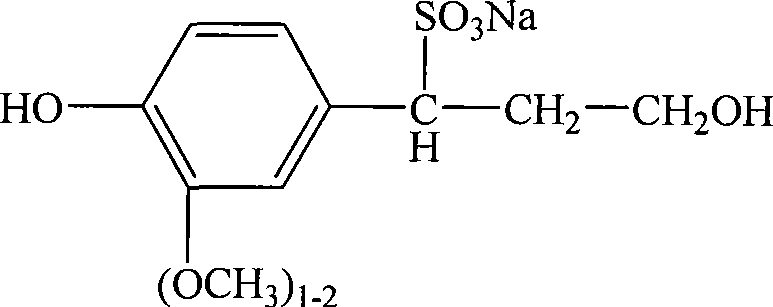

Method for preparing modified kraft pulp sodium lignosulphonate

A technology of sodium lignosulfonate and kraft pulp, which is applied in the directions of lignin derivatives, chemical instruments and methods, organic chemistry, etc., can solve the problems of unstable quality, large molecular weight distribution range of lignin, poor thermal stability, etc. Achieve the effect of process science, high economic value and environmental protection advantages, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

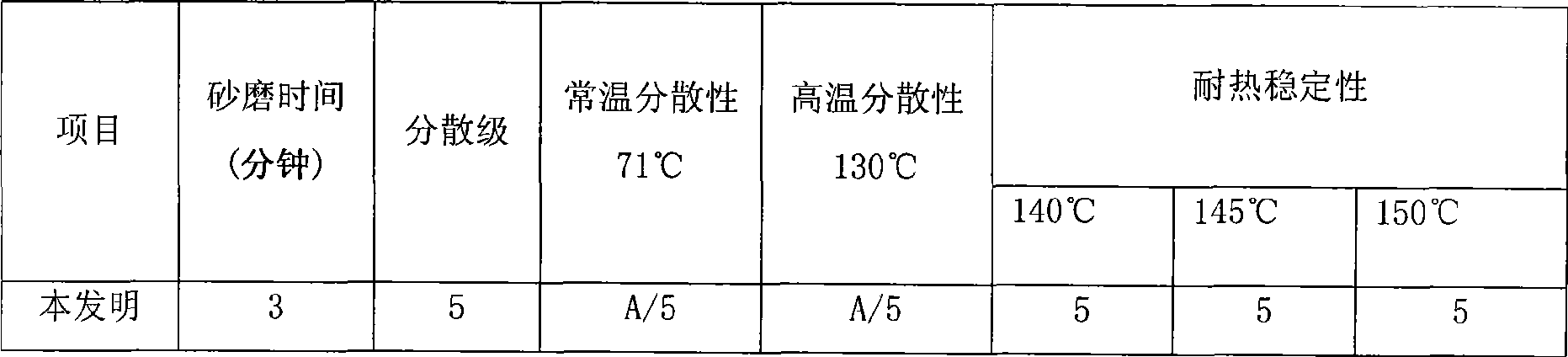

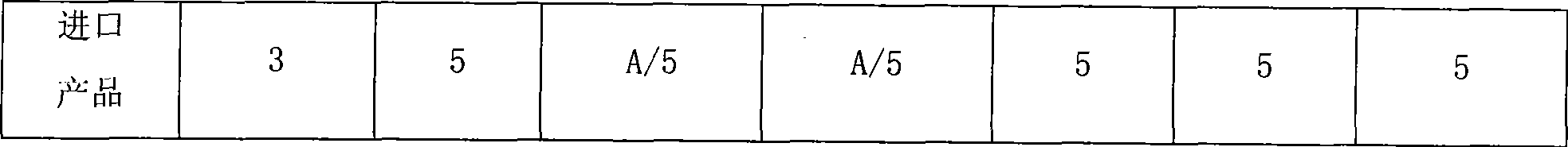

Examples

Embodiment 1

[0028] A preparation method of modified kraft pulp sodium lignosulfonate, comprising the following specific steps:

[0029] a: Acid analysis: Introduce purified CO rich in kraft pulp black liquor at 70°C to 80°C 2 After 8 hours of exhaust gas from the flue, macromolecular-level crude lignin can be obtained;

[0030] b: Desalting: washing the macromolecular grade crude lignin obtained in step a with hot water to remove inorganic salts in the crude lignin to obtain macromolecular grade refined lignin.

[0031] c: Sulfonation condensation reaction: Dissolve refined lignin in 40% sodium hydroxide lye, and then add sodium sulfite at a weight ratio of 1:1.0 between refined lignin and sodium sulfite at a temperature of 170°C. React for 8 hours, then add formaldehyde and continue to react for 10 hours to obtain a modified kraft pulp sodium lignosulfonate solution; the weight ratio of the amount of formaldehyde to refined lignin is 0.5:1.

[0032] d: Removal of tall oil: the modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com