High molecular weight and moderate sulfonation degree lignin-based pesticide dispersant and its preparation method

A lignin-based, high-molecular-weight technology, applied in botany equipment and methods, biocides, animal repellants, etc., can solve the problems of small molecular weight and poor dispersion performance of dispersants, and achieve strong adsorption stability and strong adsorption Ability, hydrophilic group and lipophilic group distribution obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

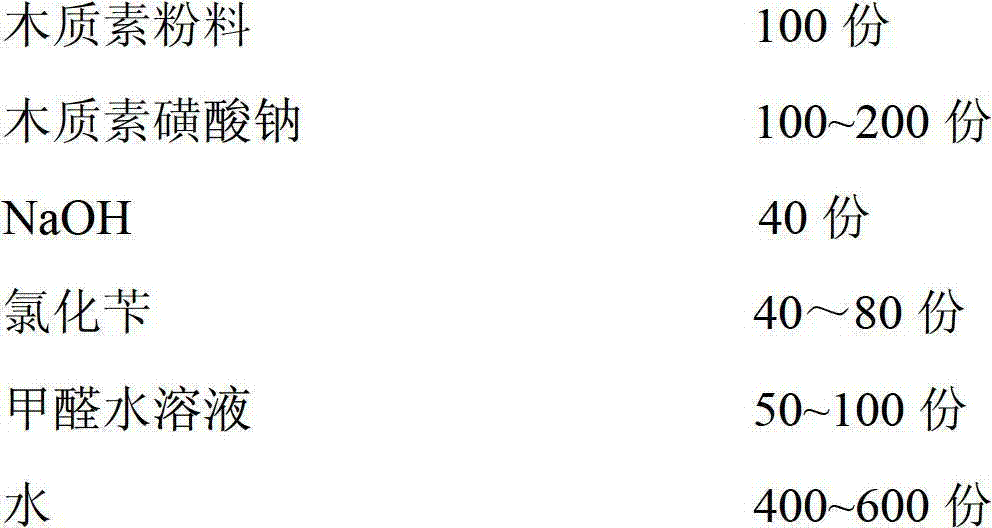

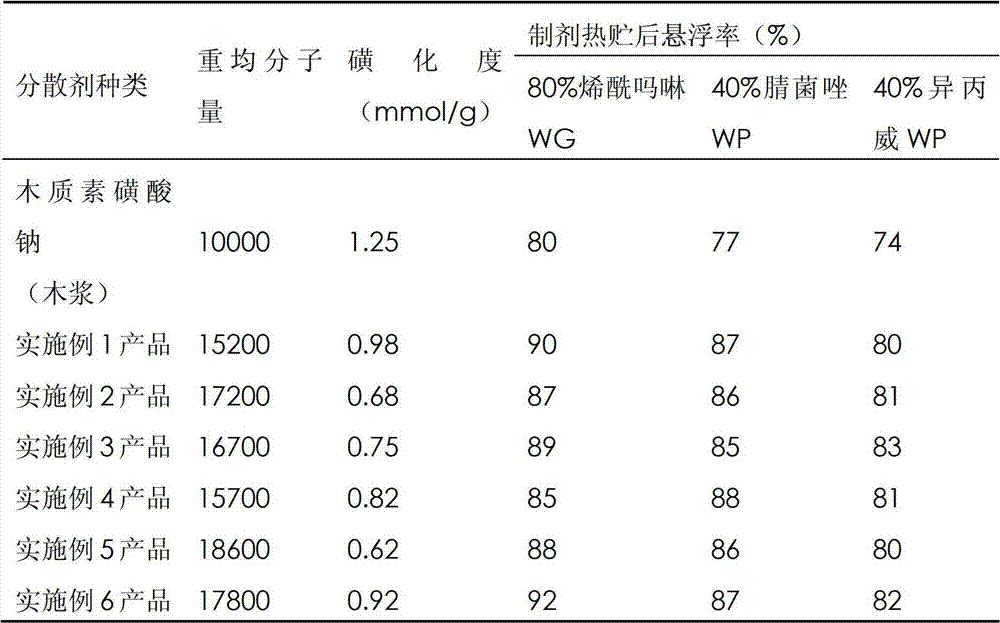

[0039] Example 1: Weigh 50g of wood pulp and papermaking black liquor powder, add 50mL, 10mol / L NaOH solution to swell at room temperature for 30min; then add 20g of benzyl chloride, stir the oil bath to 100°C and carry out etherification reaction for 3h ; Add 300 g of water, 100 g of sodium lignosulfonate, and 25 g of aqueous formaldehyde solution (formaldehyde mass content is 37%), and perform a copolymerization reaction at 85° C. for 3 h. Finally, a sulfuric acid solution with a mass concentration of 20% is used to adjust the pH to 7, and then the product is cooled to room temperature to obtain a lignin-based pesticide high-efficiency dispersant liquid product.

Embodiment 2

[0040] Example 2: Weigh 50g of bamboo pulp black liquor powder, add 50mL, 10mol / L NaOH solution to swell for 60min at room temperature; then add 30g of benzyl chloride, heat the stirring oil bath to 95°C and carry out etherification reaction for 2h; Add 200 g of water, 60 g of sodium lignosulfonate, and 40 g of formaldehyde aqueous solution (formaldehyde mass content is 37%), and perform a copolymerization reaction at 95° C. for 2 hours. Finally, a nitric acid solution with a concentration of 20 wt% is used to adjust the pH to 7, and then the product is cooled to room temperature to obtain a liquid product of a lignin-based pesticide high-efficiency dispersant.

Embodiment 3

[0041] Example 3: Weigh 50g of wheat straw pulp black liquor powder, add 50mL, 10mol / L NaOH solution to swell for 40min at room temperature; then add 20g of benzyl chloride, heat the stirring oil bath to 110°C and carry out etherification reaction for 4h; Add 300 g of water, 70 g of sodium lignosulfonate, and 50 g of formaldehyde aqueous solution (formaldehyde mass content is 37%), and carry out a copolymerization reaction at 95° C. for 2 h. Finally, a hydrochloric acid solution with a concentration of 20 wt% is used to adjust the pH to 8, and then the product is cooled to room temperature to obtain a lignin-based pesticide high-efficiency dispersant liquid product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com