Sulfonated polystyrene microsphere immobilized alkaline protease and preparation method thereof

A technology of sulfonated polystyrene and polystyrene microspheres, applied in biochemical equipment and methods, immobilized on/in organic carriers, enzymes, etc., can solve the problem of unloaded sulfonated polystyrene microspheres Alkaline protease and other problems, to achieve the effects of good dispersibility, strong electronegativity, high specific surface area, and simple and convenient method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

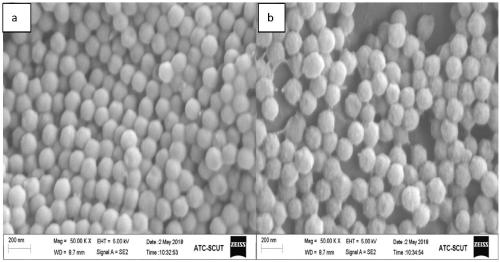

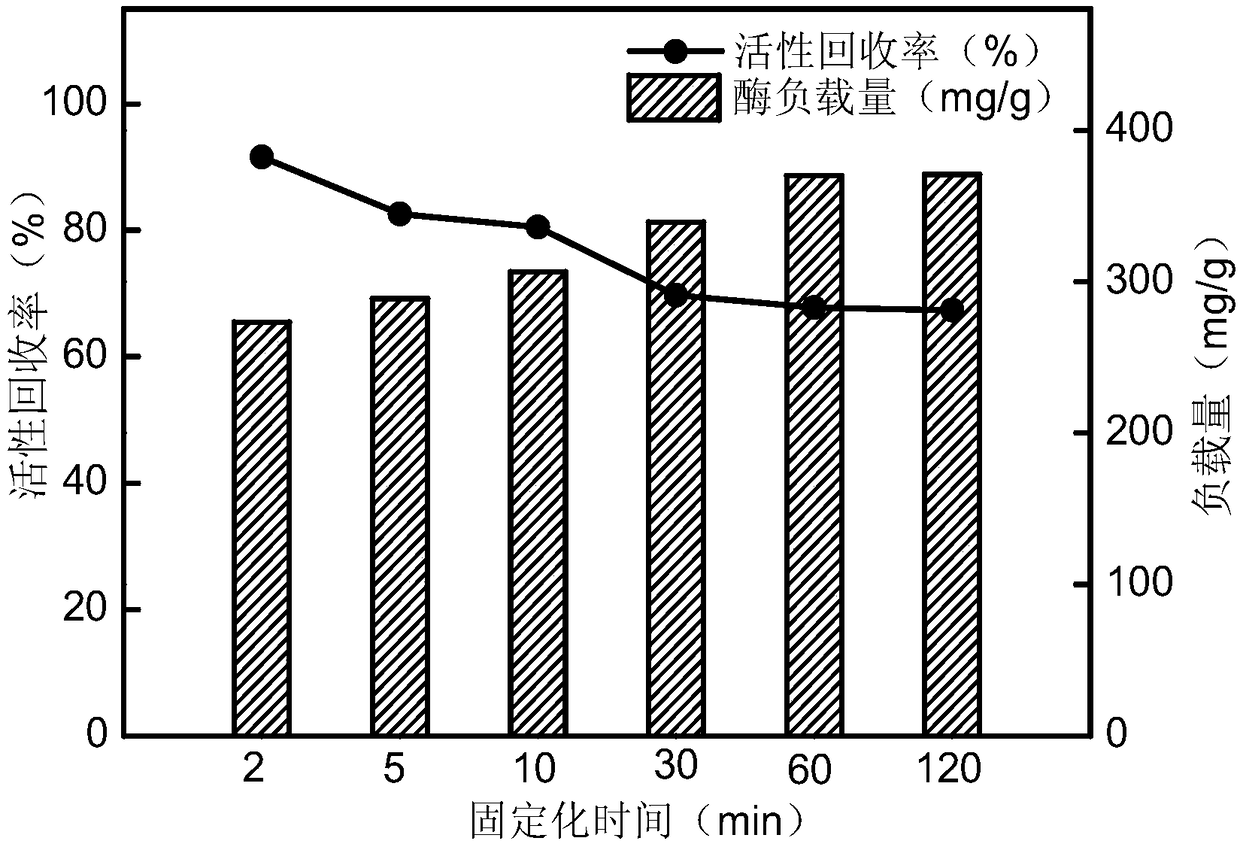

[0029] Prepare a 4.5 mg / mL Bacillus subtilisin solution with distilled water, and add the nano-sulfonated polystyrene microsphere solution that has been uniformly dispersed by ultrasound to make the final concentration of the microspheres 1 mg / mL. At room temperature, immobilize with magnetic stirring for 2 minutes, centrifuge and wash with water three times to obtain a precipitate of enzyme immobilized on sulfonated polystyrene microspheres. Collect the combined supernatant, measure the protein content according to the Coomassie Brilliant Blue method, and calculate the enzyme load; collect the precipitate, measure the enzyme activity according to the national industry standard SB / T 10317 protease activity assay, and calculate the enzyme activity recovery rate, the calculation formula is as follows (1 ), (2) shown. The activity recovery rate of the immobilized enzyme was 91.59%, and the loading capacity was 273.36 mg / g.

Embodiment 2

[0036] Prepare a 4.5 mg / mL Bacillus subtilisin solution with distilled water, and add the nano-sulfonated polystyrene microsphere solution that has been uniformly dispersed by ultrasound to make the final concentration of the microspheres 1 mg / mL. At room temperature, immobilized by magnetic stirring for 5 min, centrifuged, and washed with water three times to obtain sulfonated polystyrene microspheres immobilized enzyme, the activity recovery rate was 82.55%, and the loading capacity was 288.6 mg / g.

Embodiment 3

[0038] Prepare a 4.5 mg / mL Bacillus subtilisin solution with distilled water, and add the nano-sulfonated polystyrene microsphere solution that has been uniformly dispersed by ultrasound to make the final concentration of the microspheres 1 mg / mL. At room temperature, immobilized by magnetic stirring for 10 min, centrifuged, washed with water three times to obtain sulfonated polystyrene microspheres immobilized enzyme, the activity recovery rate was 80.49%, and the loading capacity was 306.38 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Loading capacity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com