Automatic feeding type no-clean burrstone mill for soybeans, peanuts and rice

An automatic feeding, no-cleaning technology, applied in cocoa, grain processing, food science and other directions, can solve the problems of low processing efficiency and difficult to meet market needs, and achieve the effects of convenient operation, remarkable practicability and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

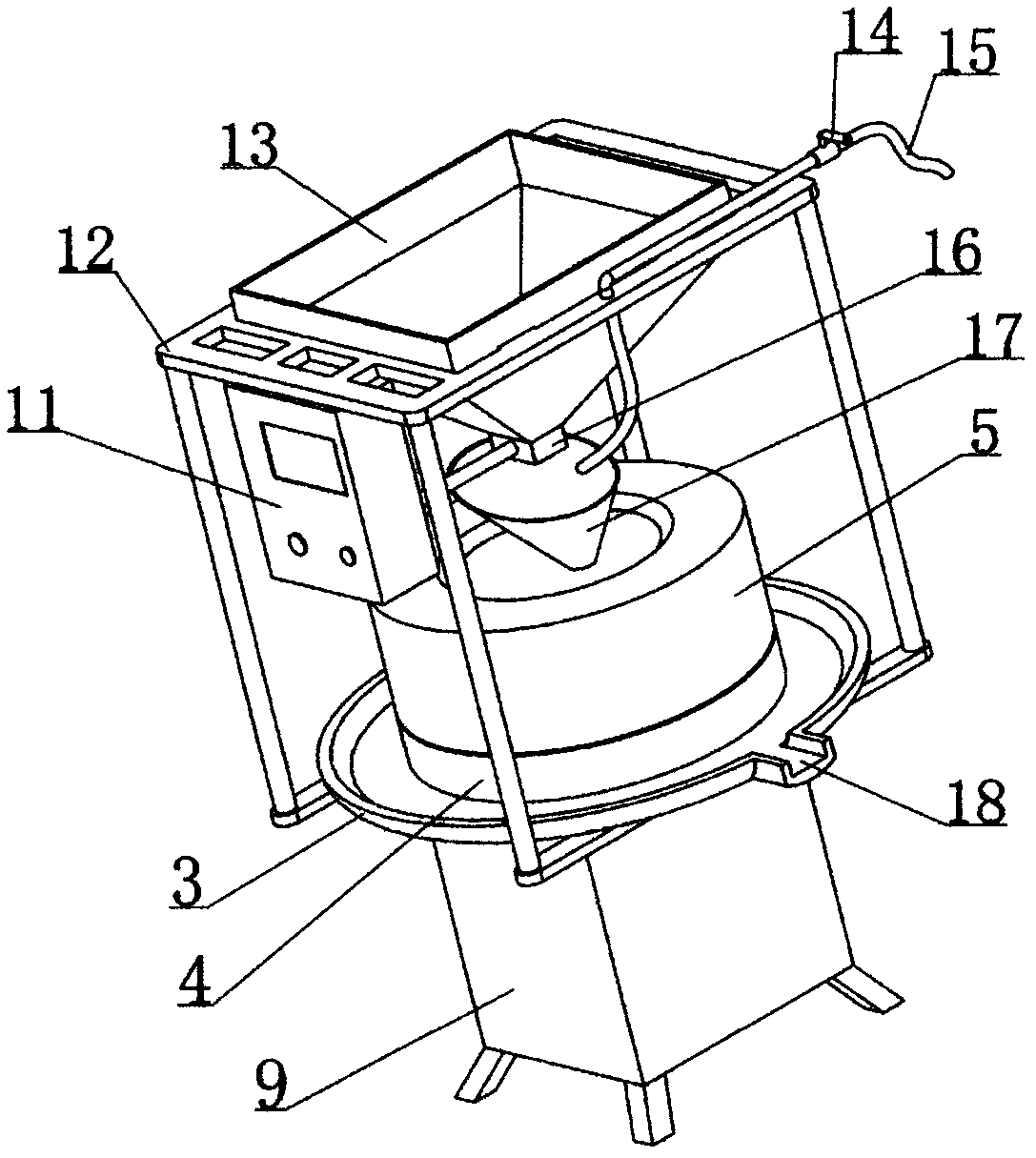

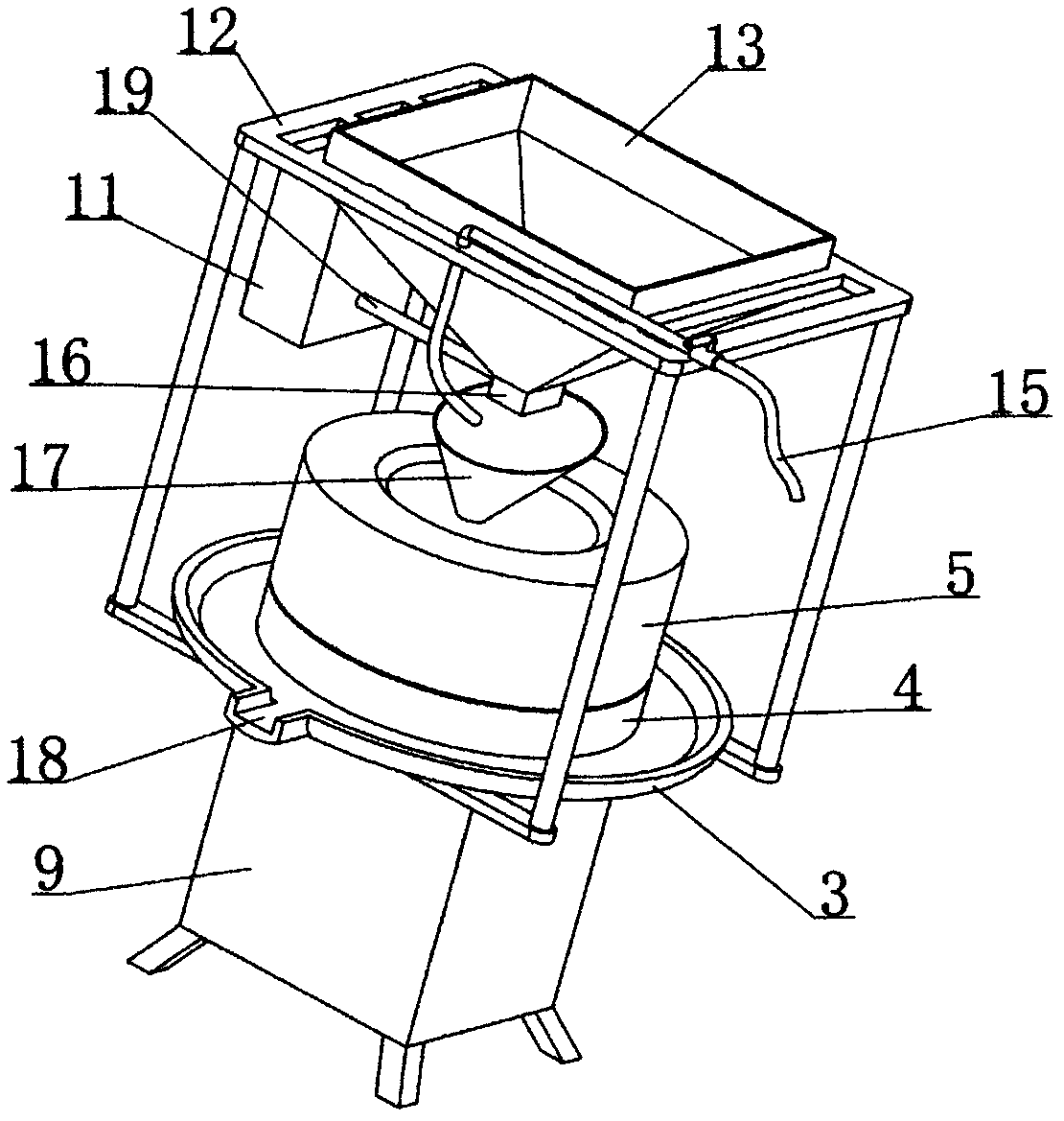

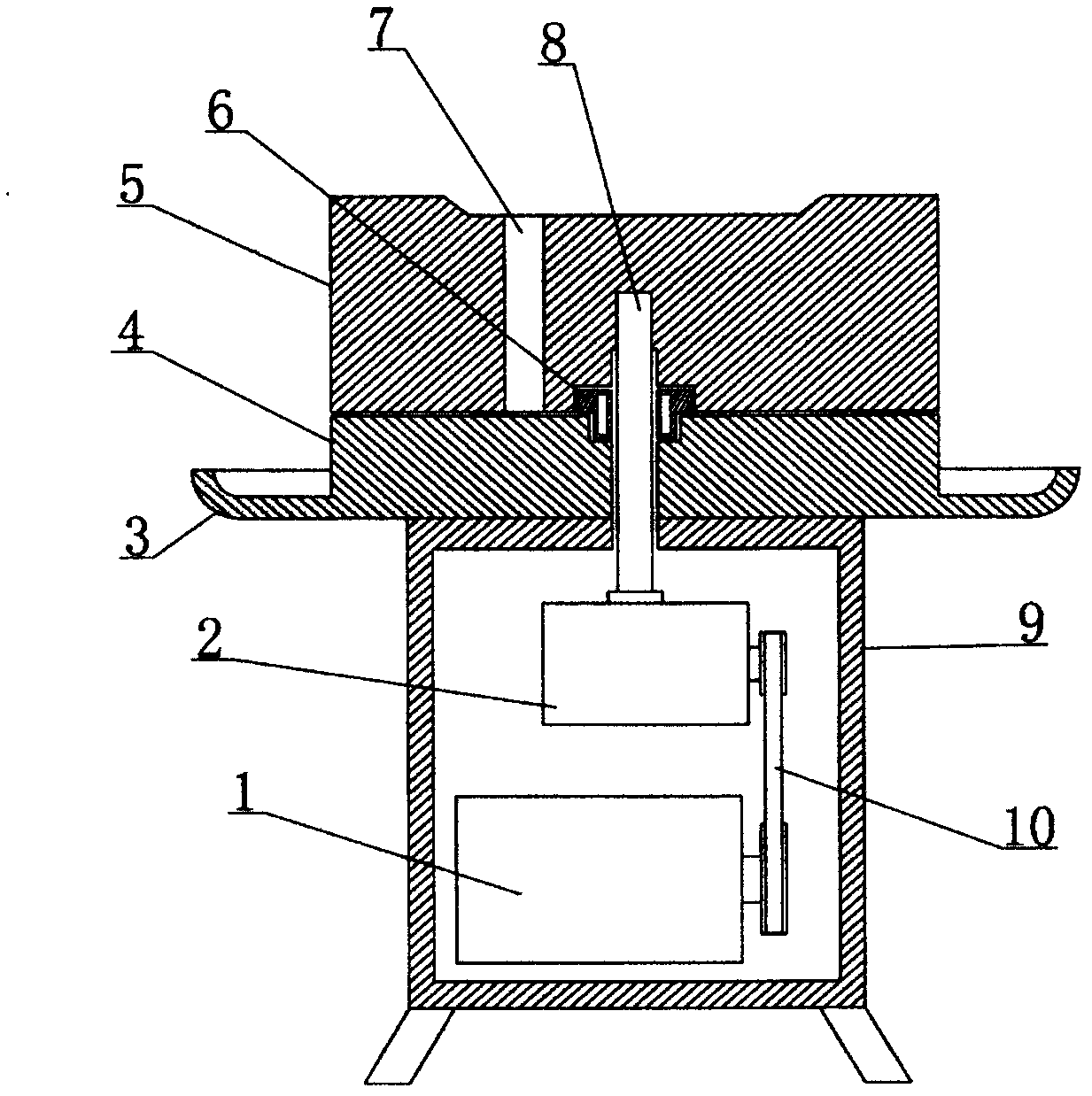

[0010] See attached figure 1 , 2 , 3, the base 9 is fixed with a lower grinding disc 4, and the periphery of the lower grinding disc 4 is provided with a pulp collecting disc 3, and the outer edge of the pulp collecting disc 3 is higher, which can prevent the grain paste from overflowing. Slurry port 18; the lower grinding disc 4 is supported by the bearing 6 to have the upper grinding disc 5 which is ground into each other, and the upper grinding disc 5 is provided with a feeding hole 7, and a feeding funnel 17 is fixed on the feeding hole 7, and the center of the circle below the upper grinding disc 5 is connected with the drive The shaft 8 is fixedly connected, and the driving shaft 8 passes through the lower grinding disc 4 and is connected with the power unit in the base 9;

[0011] See attached figure 1 , 2 As shown, the top of the upper grinding disc 5 is provided with a hopper 13 fixed by a bracket 12, the bottom of the hopper 13 is provided with a discharge port 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com