High-pressure tangent pump

A tangential pump, high-pressure technology, applied in the direction of pumps, pump components, non-variable pumps, etc., can solve the problems of reduced pump life, bearing heating, cavitation, etc., to achieve balanced axial force, stable operation, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

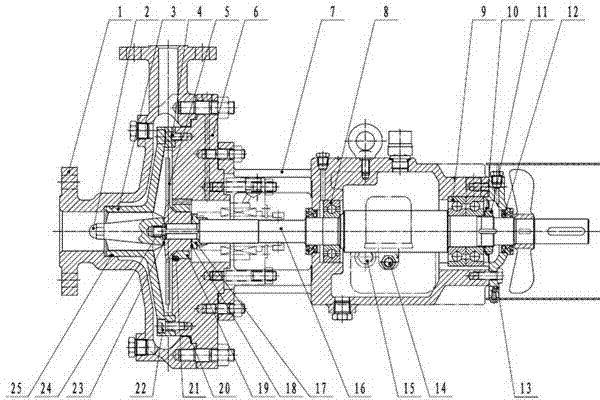

[0017] Such as figure 1 As shown, the high-pressure tangential pump includes a pump body 1, a guide vane 3, an impeller 5, an angular contact ball bearing 9, a shaft 16 and a throat bushing 19, the pump body 1 is connected to the pump cover 6, and the pump Gasket 2 20 is installed between the body 1 and the pump cover 6, the pump cover 6 is connected to the bearing frame 7, the design of the bearing frame 7 is a universal design, dozens of pumps only need one type of bearing frame, the degree of standardization is high, The guide vane 3 is fixedly mounted on the pump cover 6 through a cylindrical pin 4 and two screws 22, an O-ring 25 is installed between the guide vane 3 and the pump body 1, and the impeller 5 is located on the guide vane 3 and the pump cover 6, and fixedly installed on the shaft 16 through the impeller nut 2 and the wire thread sleeve 24. A gasket 3 23 is installed between the impeller 5 and the impeller nut 2, in order to ensure that the impeller 5 and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com