Symmetrical series tri-rotor screw compressor

A technology of screw compressor and three rotors, which is applied in the direction of rotary piston machinery, mechanical equipment, machine/engine, etc., to achieve the effect of improving high pressure resistance, force characteristics, vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the accompanying drawings and in combination with embodiments. However, the invention is not limited to the examples given.

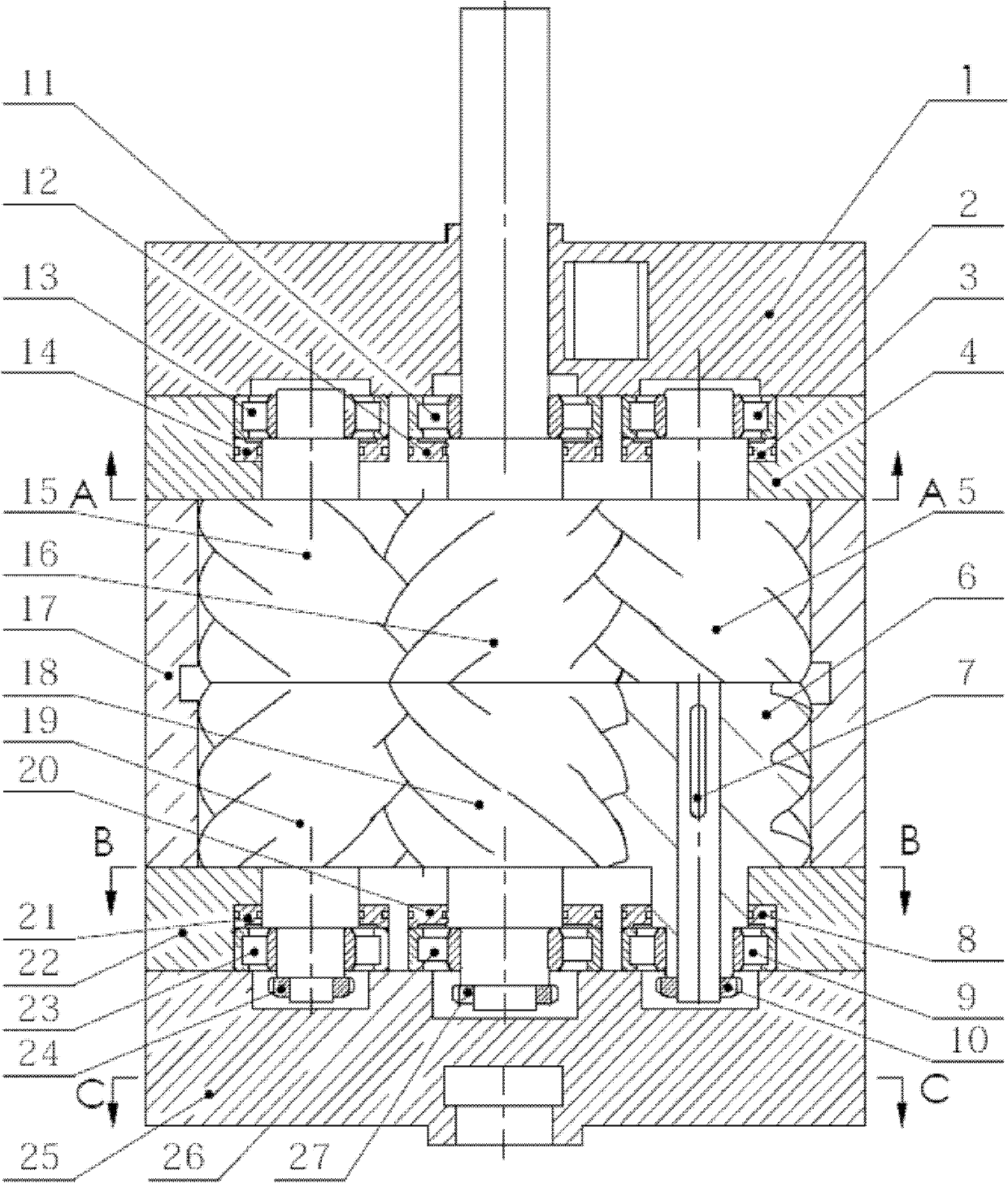

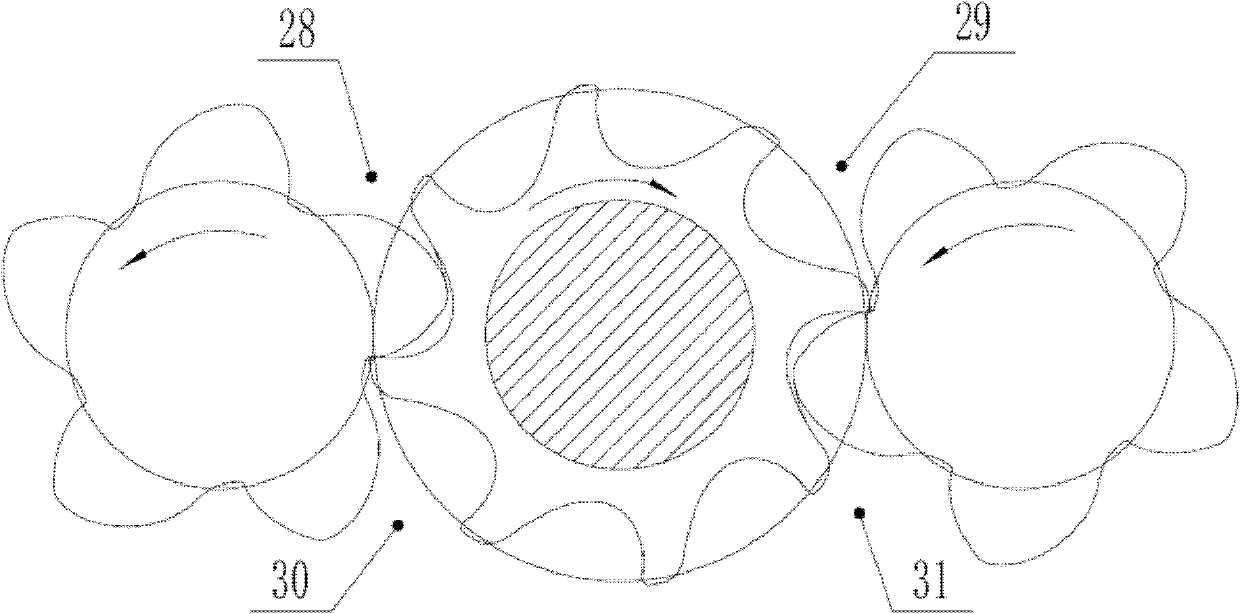

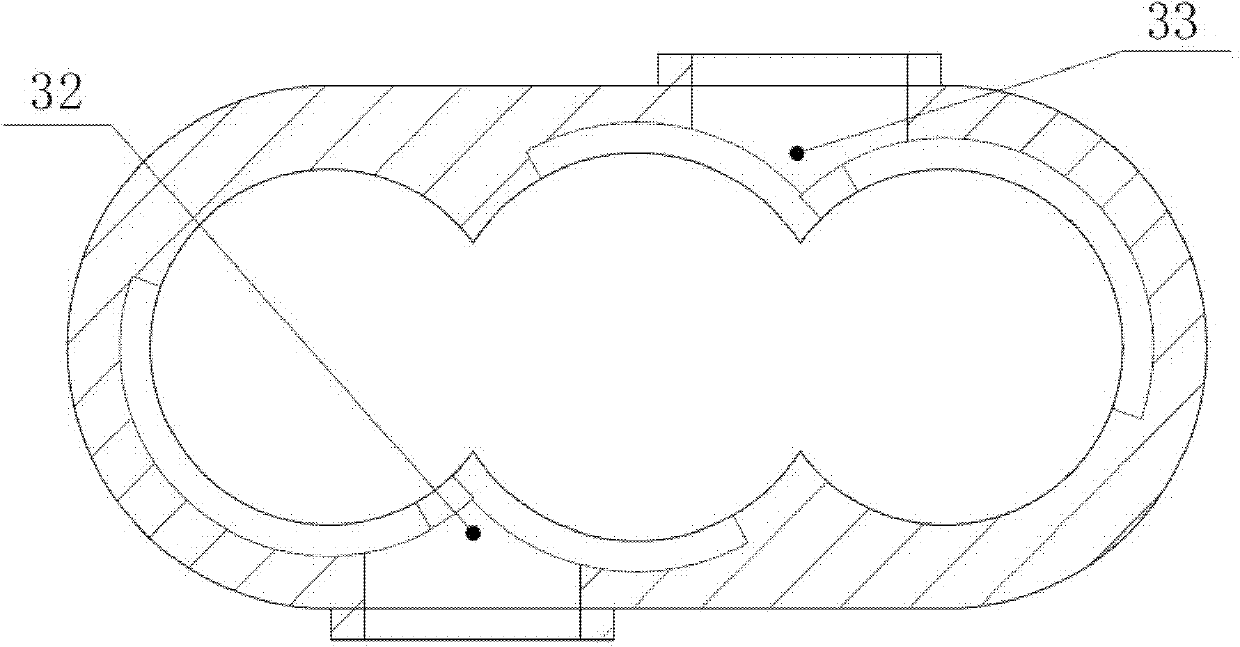

[0019] refer to figure 1 , the present invention includes a compressor body 17, on which three interlinked cavities for defining three parallel rotors are opened, and the first and second screw rods 16, 18 of the active rotor are mounted on the compressor body from top to bottom. In the cavity in the middle of the body 17, the other two symmetrical cavities on both sides of the middle cavity are respectively equipped with the driven rotor first screw rod 5, 15, the driven rotor screw rod 5, 15 and the driven rotor screw rod 16, 18 adapted to the driving rotor first and second screw rods 16, 18. The second screw rods 6, 19 and the circumferential positioning key 7 for preventing the relative rotation of the two screw rods forming the rotor, the front exhaust bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com