Multi-stage submersible pump system

A submersible pump and pump pool technology, applied in the field of centrifugal pumps, can solve the problems of difficult maintenance of pump shaft seals, low reliability, and large system cold loss, and achieve the effects of small loss, improved efficiency, and low flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

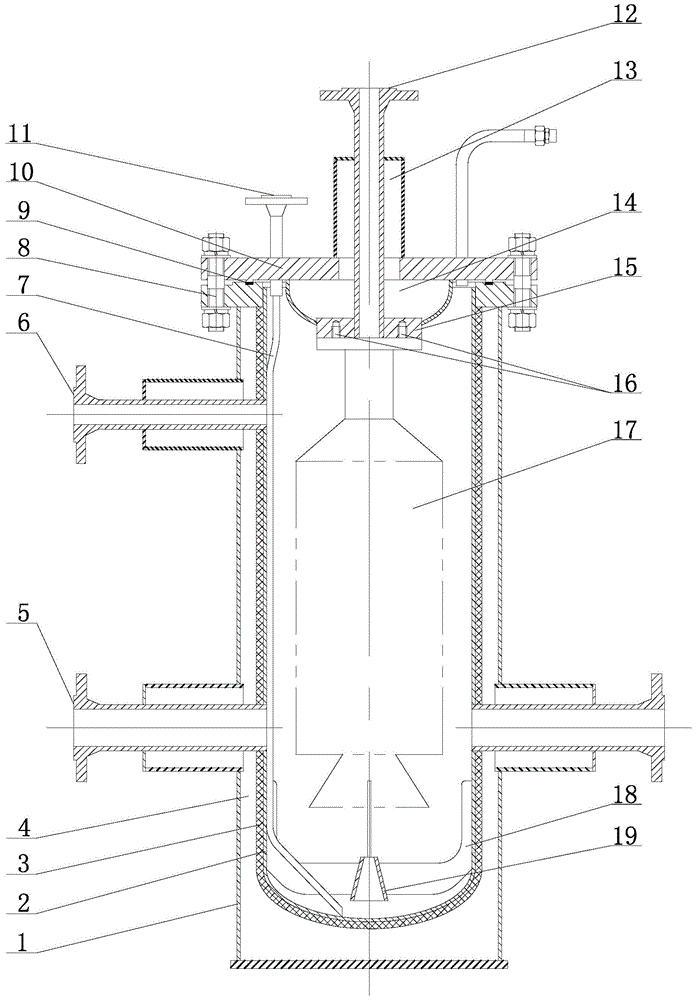

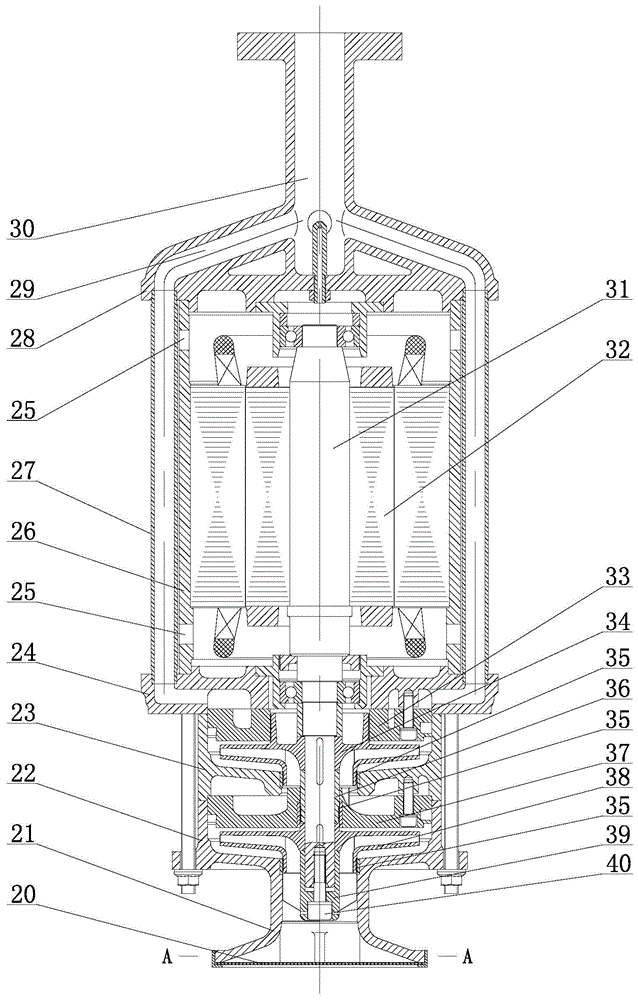

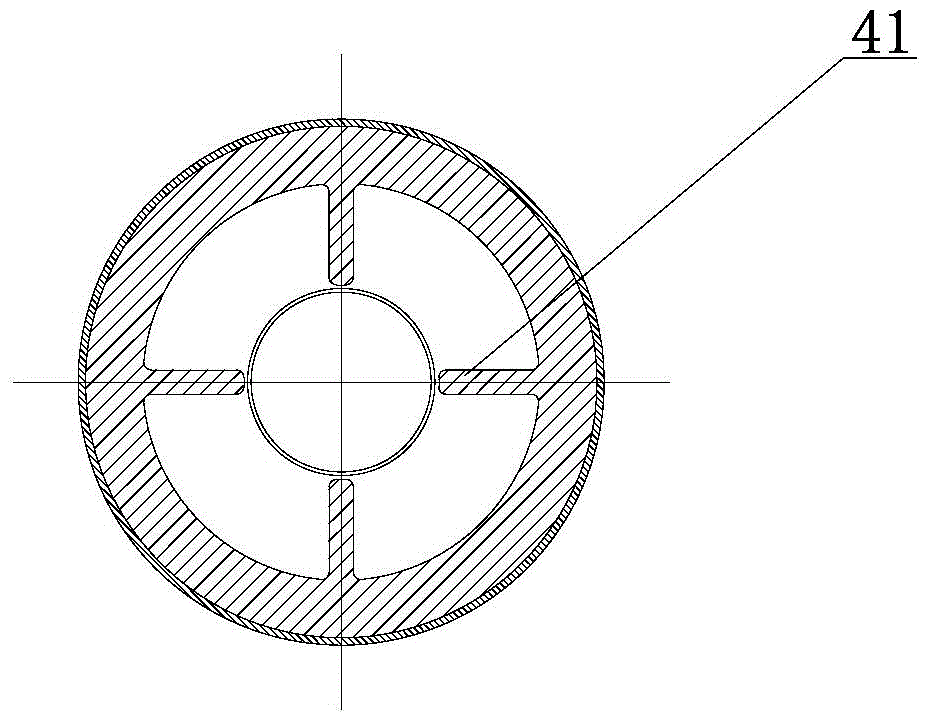

[0028] like Figure 1~3As shown, the multistage submersible pump system of the present invention includes a pump pool and a pump body 17, the pump body 17 is installed in the pump pool, and the pump body 17 includes a pump casing, a motor rotor 32, a central shaft 31 and a shaft end screw 40 The inducer 39, the first-stage impeller 38, the first-stage guide vane 37, the shaft sleeve 36, the last-stage impeller 34 and the last-stage guide vane 33 fastened on the central shaft 31, the pump casing includes sequentially connected from bottom to top The suction section 22, the middle section 23, the lower end cover 24, the motor housing 26 and the upper end cover 28, the upper end cover 28 adopts integral casting, the upper and lower end covers are connected through at least 4 outlet pipes 27, each flow channel in the upper end cover 28 29 and the cross-section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com