Bearing for main feed water pump

A technology for main feedwater pumps and bearings, which is applied to parts, pumps, and pump components of pumping devices used for elastic fluids, and can solve the problem of insufficient balance of the axial force of the pump shaft, damage to the pump shaft, and endangering the safety of the main feedwater pump Operation and other problems to achieve the effect of ensuring safe operation and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

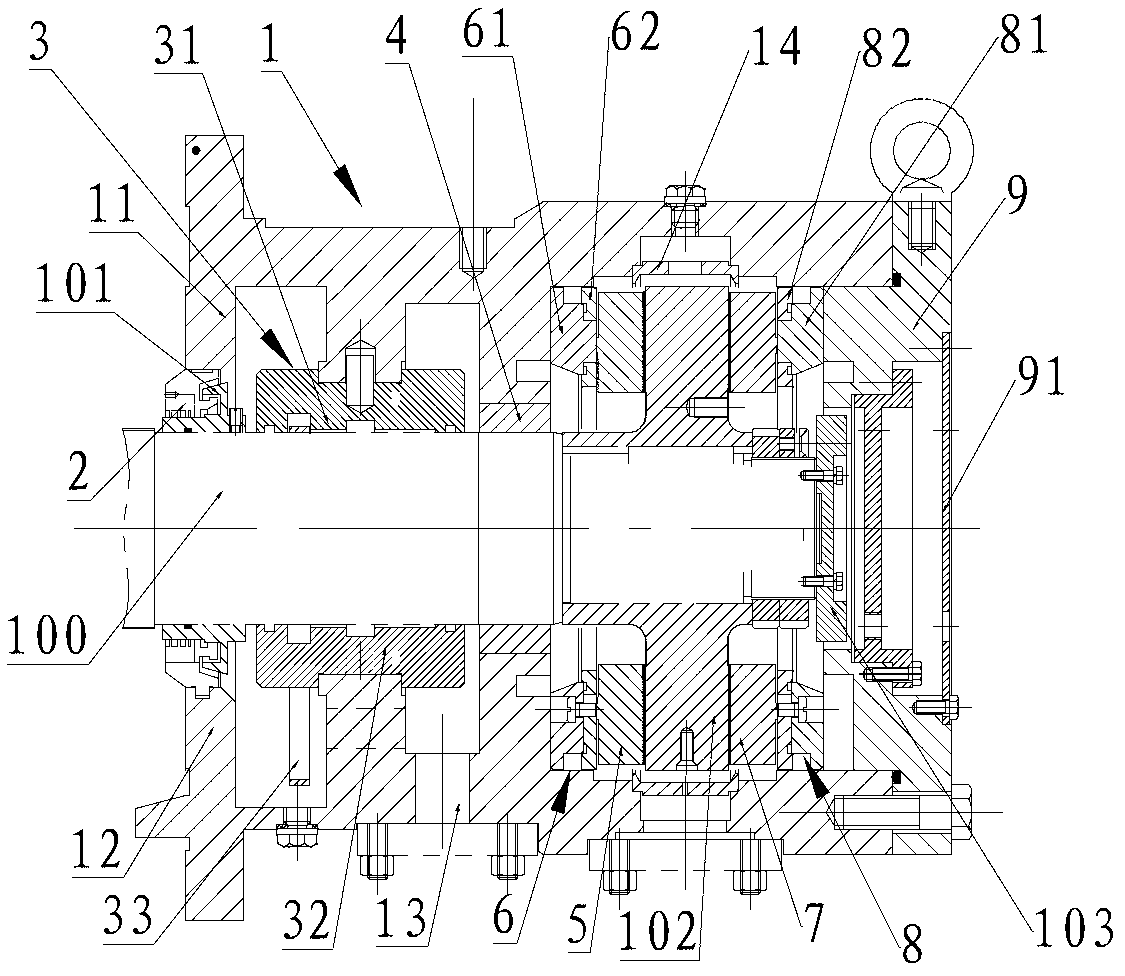

[0019] see figure 1 In order to better understand the technical solution of the present invention, the inventors of the present invention will describe in detail below through specific embodiments in conjunction with the accompanying drawings:

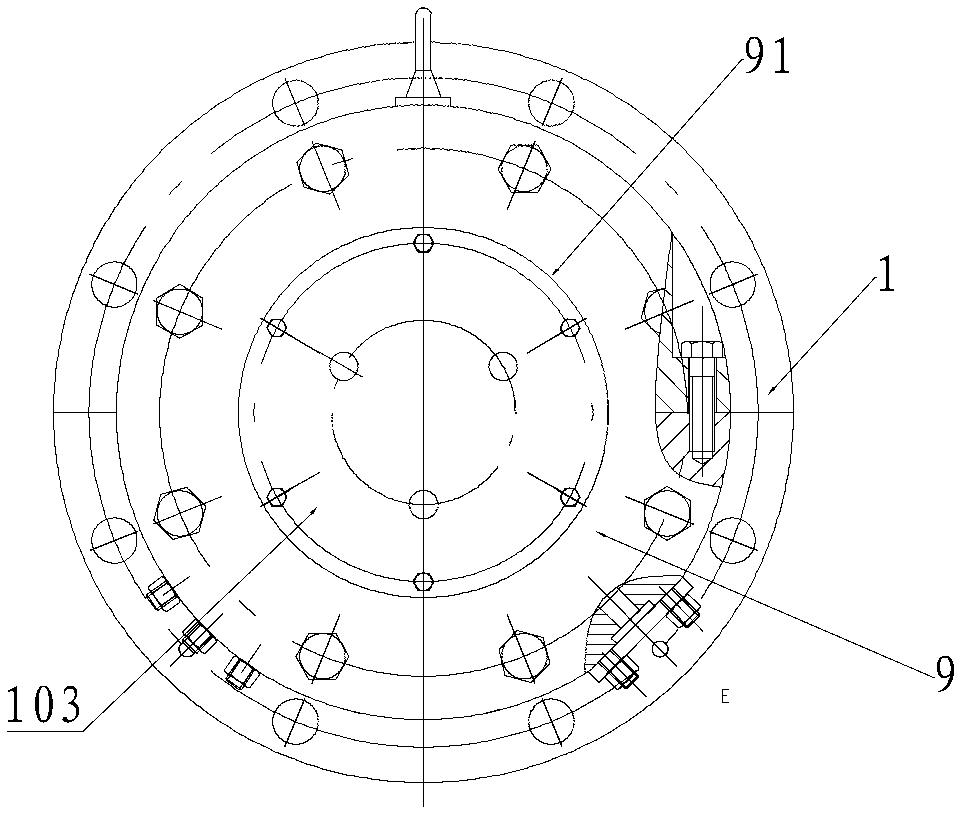

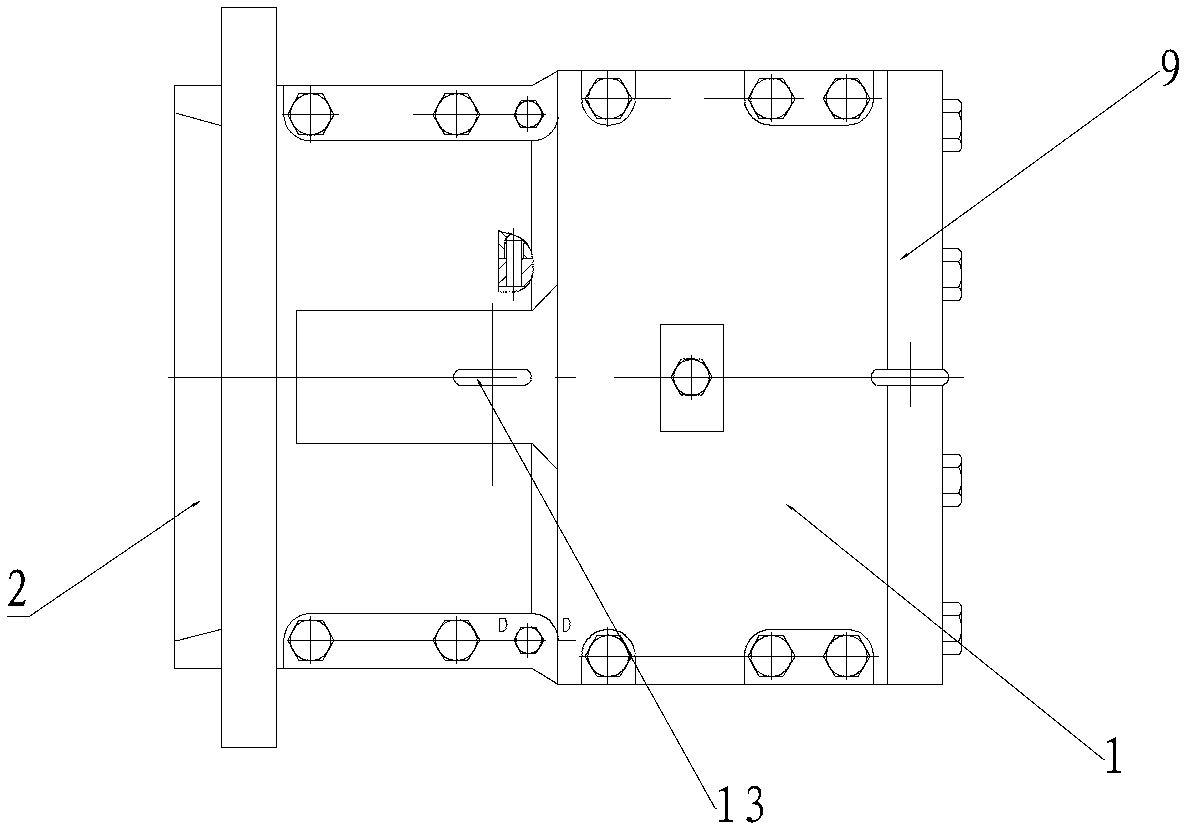

[0020] see figure 1 , a bearing used in the main feedwater pump of the present invention is sleeved on the non-driving end of the pump shaft 100 of the main feedwater pump. The bearing includes an oil retaining plate 101, a thrust plate 102, and an axial displacement measuring plate 103 fixedly sleeved on the pump shaft 100, and an oil retaining plate 101, a thrust plate 102, and an axial displacement measuring plate 103 on the outer circumference of the bearing. Bearing seat 1. Wherein, a front end bearing cover 2 is provided between the oil deflecting plate 101 and the radial direction of the bearing seat 1, and the front bearing end cover 2 and the bearing seat 1 are fixed by clamping. In order to facilitate the clamping connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com