Sewage pump with automatic axial thrust balancing function

A technology of automatic balance and axial force, which is applied in the direction of components, pumps, pump components, etc. of pumping devices used for elastic fluids, and can solve the problems of large power consumption of motors and great influence on pump efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

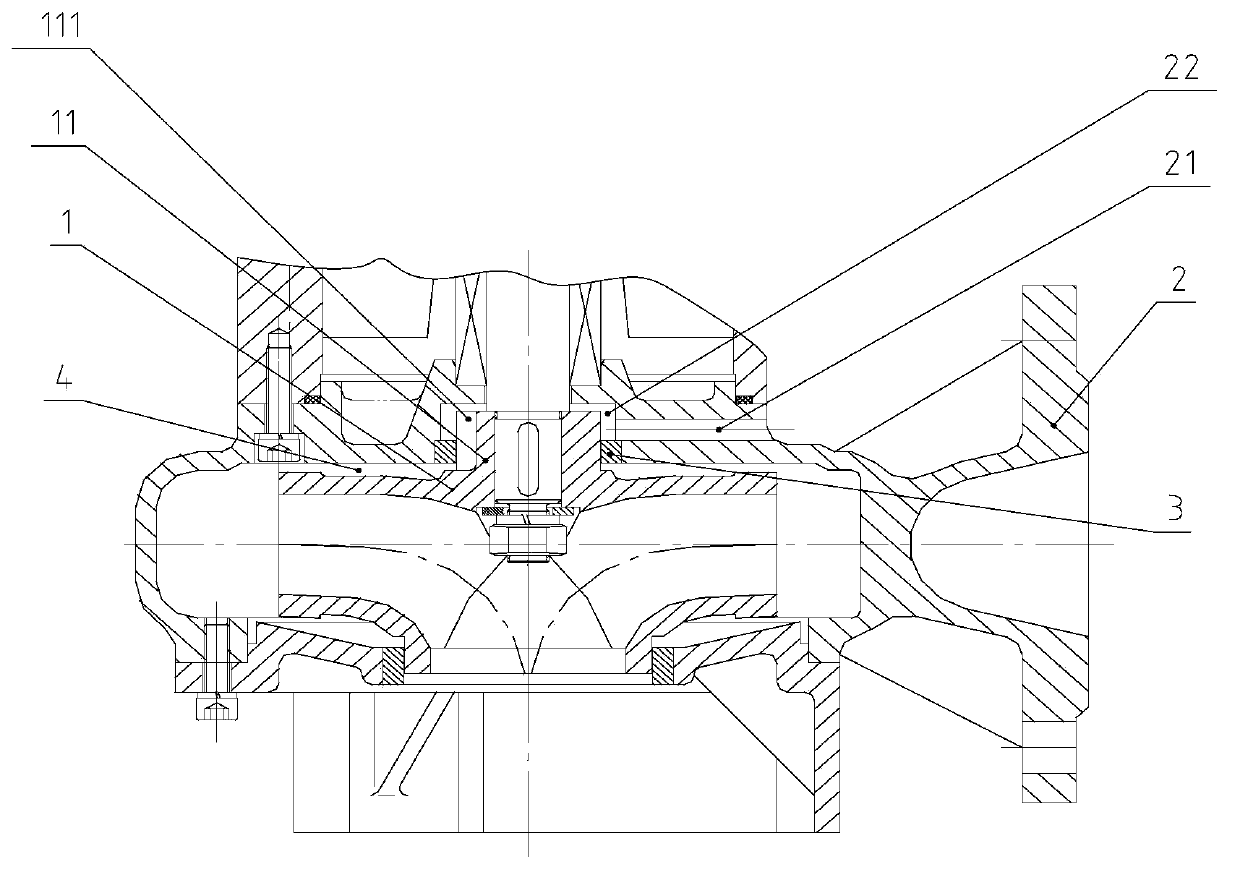

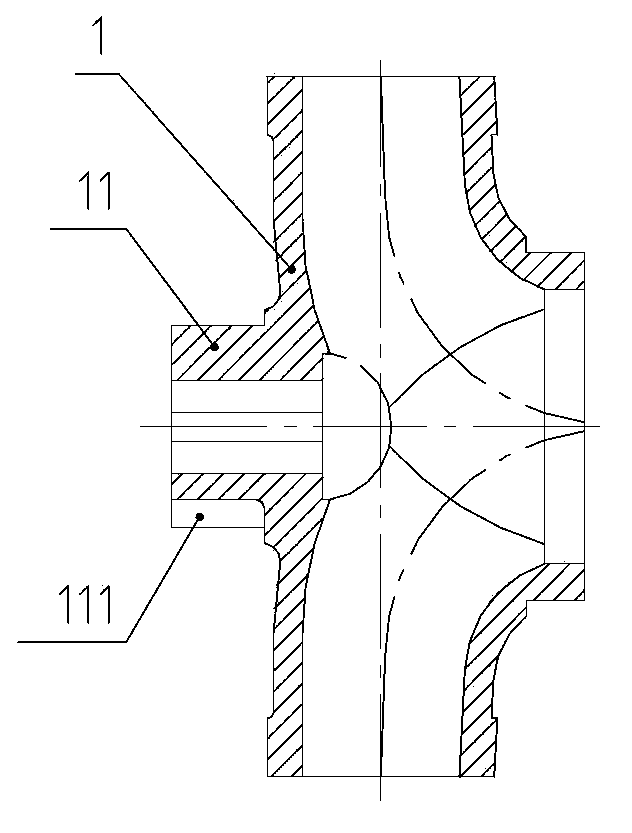

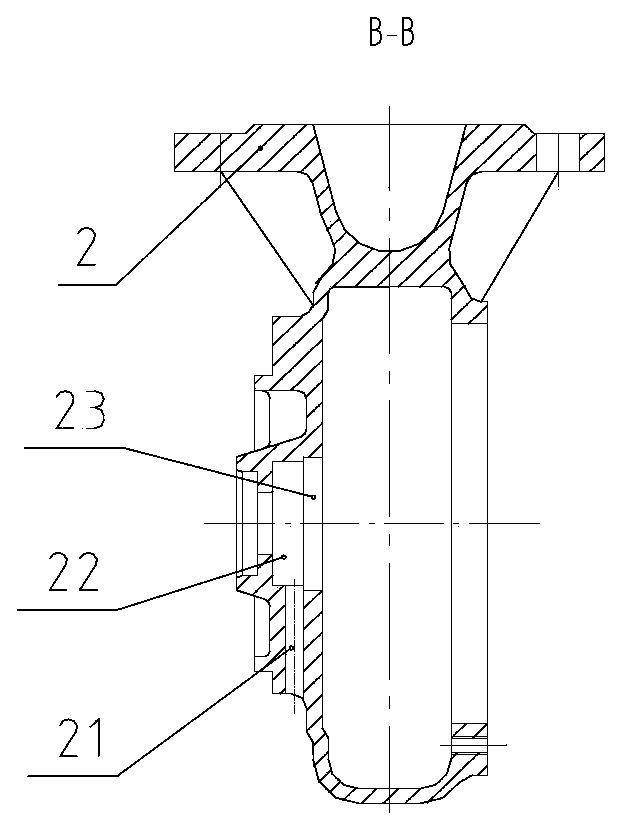

[0021] Such as Figure 1-Figure 5 As shown, a sewage pump with the function of automatically balancing the axial force includes a pump body 2 and an impeller 1. The impeller 1 is provided with a hub 11, and the hub 11 is provided with a water tank 111. The pump The body 2 is provided with a connection hole 22 and a water outlet hole 21 , the water outlet hole 21 communicates with the connection hole 22 , and the water tank 111 is sequentially connected with the connection hole 22 and the water outlet hole 21 . The pump body 2 is inlaid with a sealing ring 3, and the outer diameter of the hub 11 and the inner diameter of the sealing ring 3 are clearance fit, and the unilateral clearance is 0.15mm. The sealing ring 3 is made of copper.

[0022] In this embodiment, the width of the water tank 111 is 4mm, and the depth is 9mm; the length of the water outlet hole 21 is 15mm, and the width is 8mm.

[0023] The working principle of the above-mentioned sewage pump with the function ...

Embodiment 2

[0025] refer to Figure 1-Figure 5 As shown, the present embodiment has the sewage pump with the function of automatically balancing the axial force, the width of the water tank 111 on the hub 11 is 8mm, and the depth is 4mm; the length of the outlet hole 21 on the pump body 2 is 22mm, and the width is 5mm. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com