Novel horizontal cantilever energy-saving two-stage pump

A two-stage pump, horizontal technology, applied in the direction of non-variable pumps, non-volume pumps, pumps, etc., can solve the problems of unbalanced axial force, inconvenient installation, power consumption, etc., to increase the outlet pressure , Prevent the bearing from falling off and prevent water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

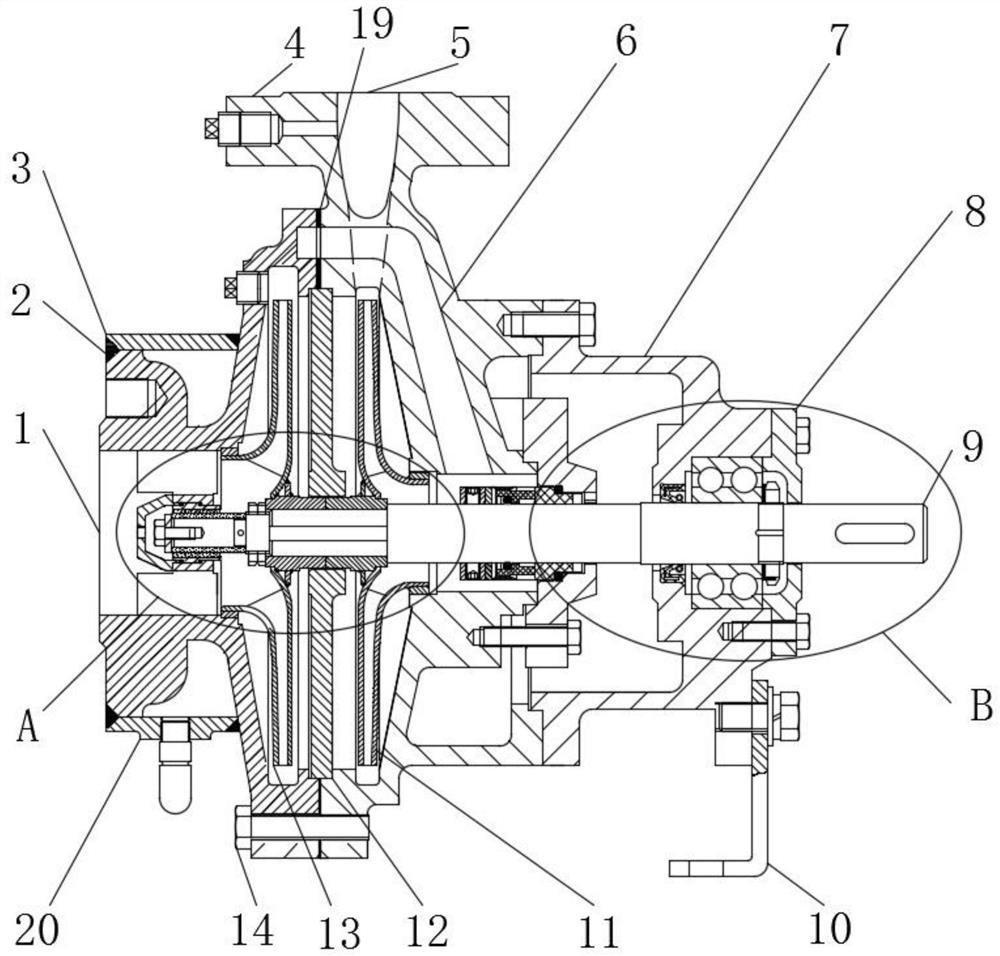

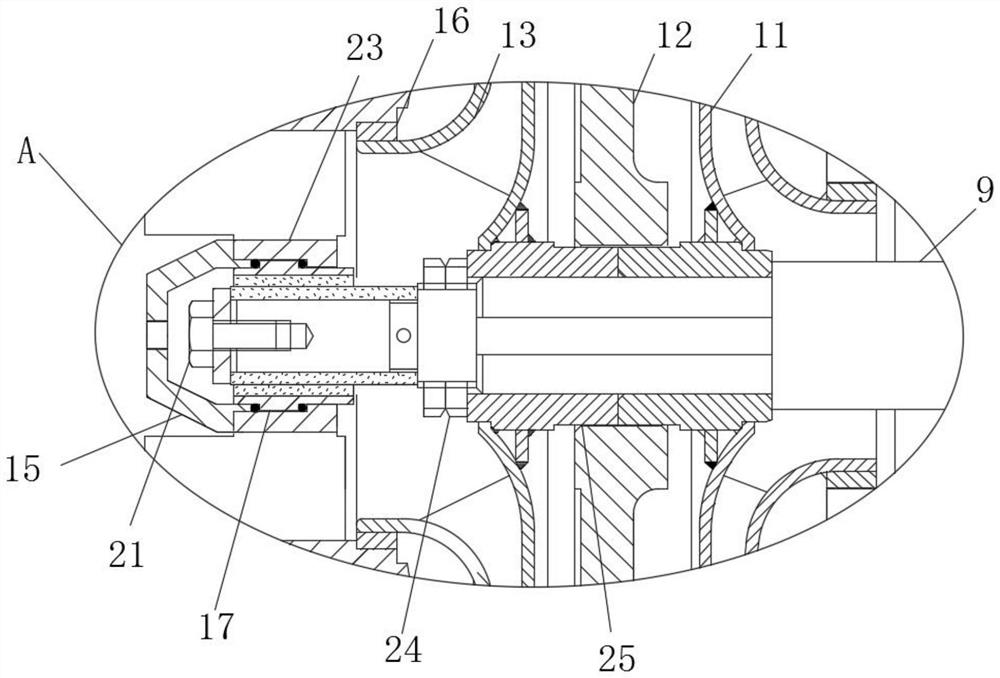

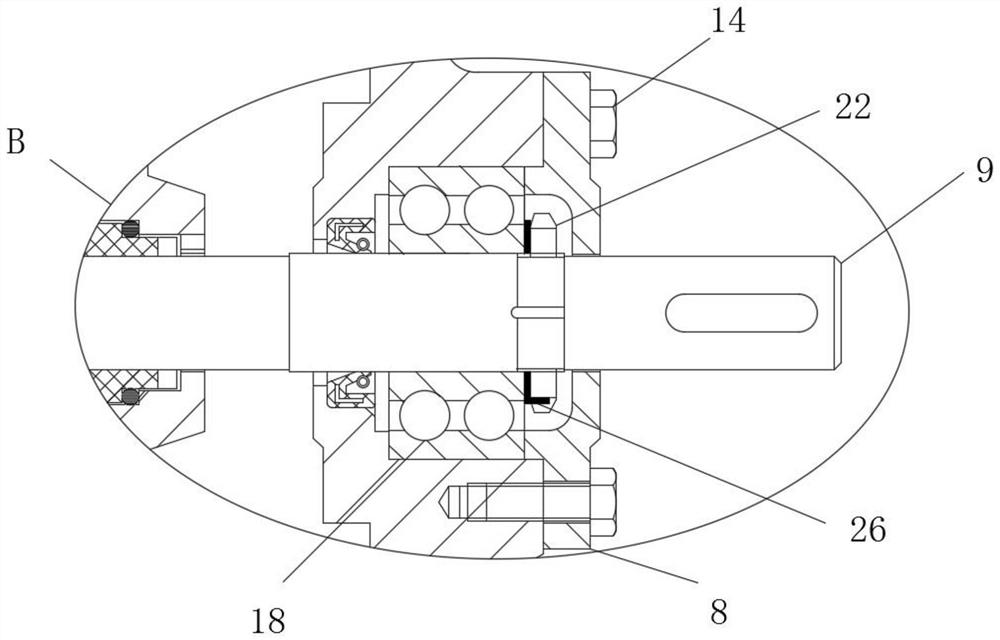

[0024] see Figure 1-3 As shown, a new horizontal cantilever energy-saving two-stage pump includes water inlet 1, heat preservation jacket 2, water inlet flange 3, pump body 4, water outlet 5, water flow channel 6, bearing bracket 7, bearing gland 8 , rotor 9, support leg 10, first impeller 11, partition plate 12, second impeller 13, bolt 14, bearing box 15, impeller mouth ring 16, inner sliding bearing 17, double row radial ball bearing 18, sealing ring 19. Two-stage pump 20, fastening bolts 21, round nuts 22, outer slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com