Impeller built-in type high-speed centrifugal pump

A high-speed centrifugal and built-in technology, which is applied in the field of centrifugal pumps to achieve the effects of compact structure, balanced axial force and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

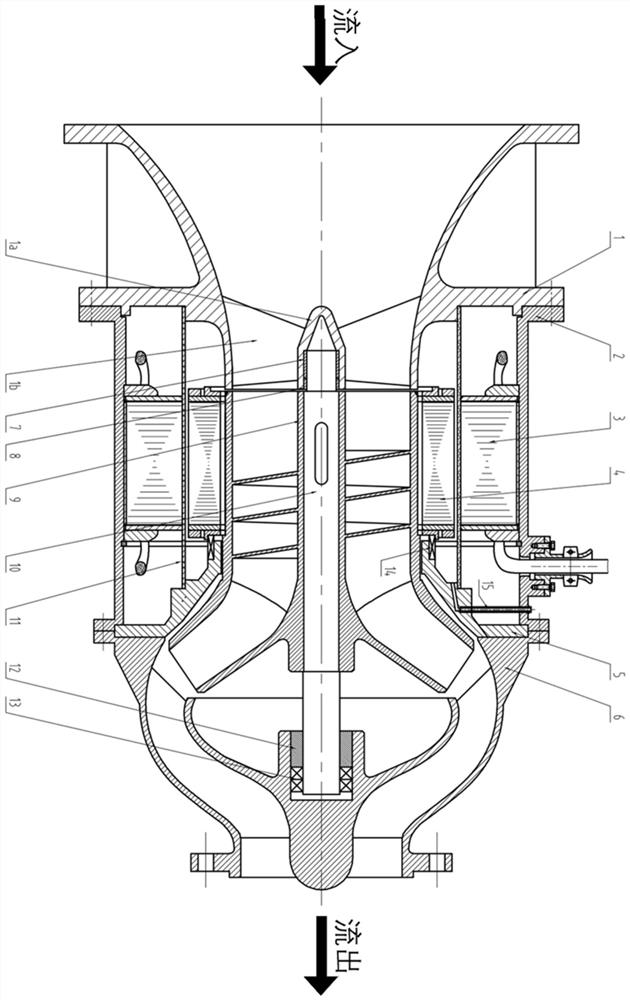

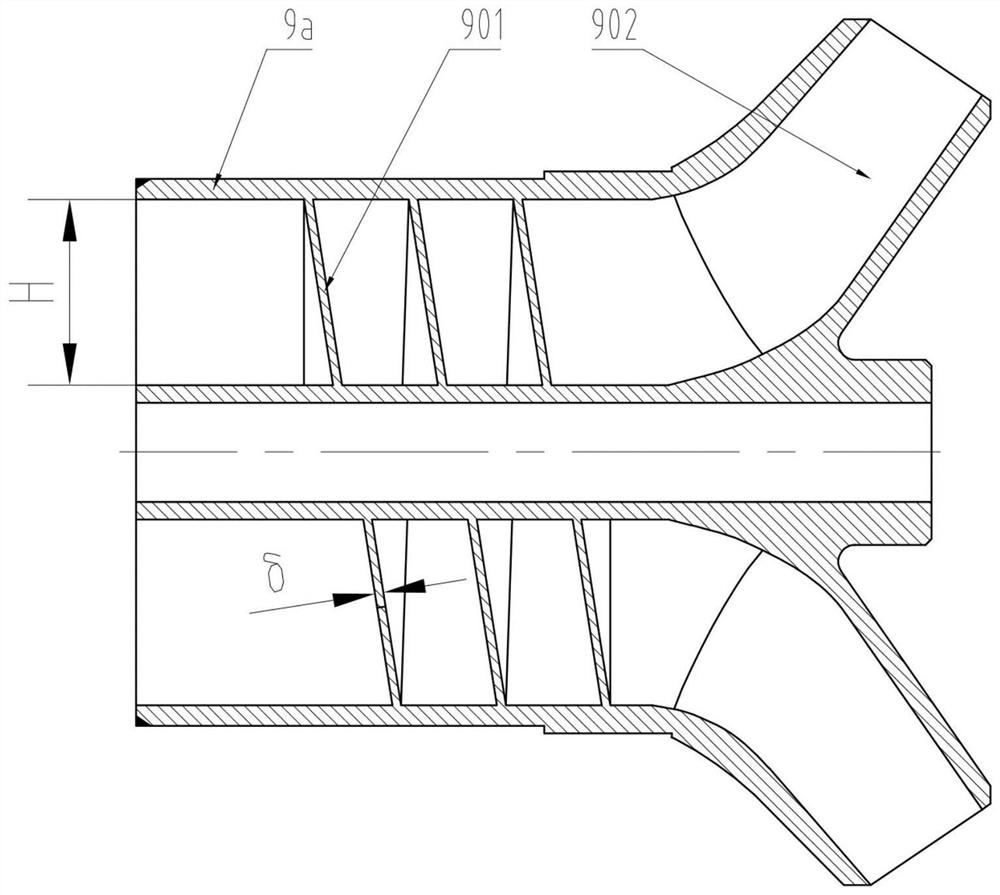

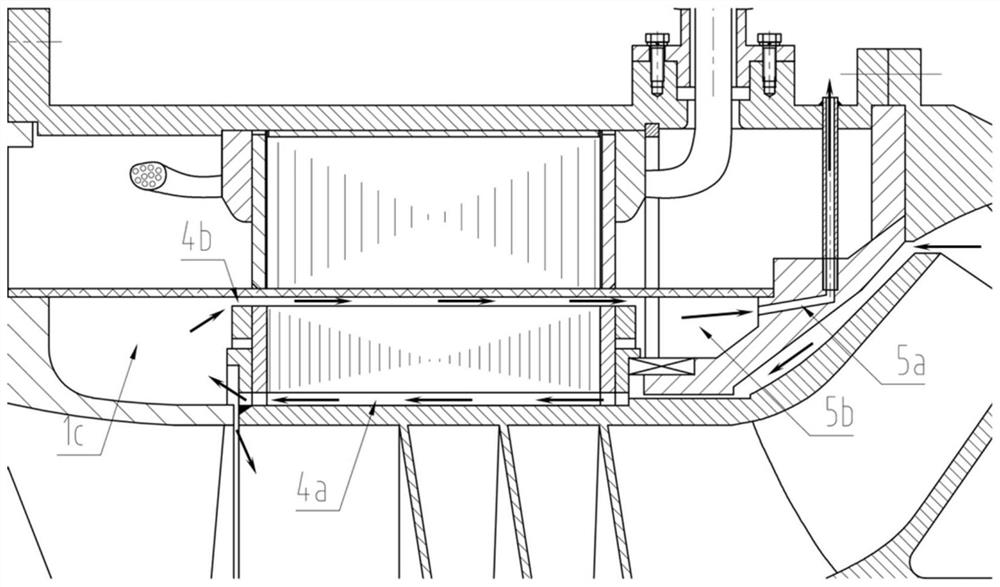

[0028] Such as figure 1 with figure 2 As shown, the impeller built-in high-speed centrifugal pump according to the present invention includes a trumpet tube 1, a motor casing 2, a motor stator 3, a motor rotor 4, a motor partition 5, a rear guide vane 6, a guide bearing 7, and a runner 9 , shaft 10 and two-way thrust bearing 13, the runner 9 is fixed on the shaft 10, the two ends of the shaft 10 are respectively equipped with a guide bearing 7 and a two-way thrust bearing 13; the horn tube 1 is installed on one end of the motor housing 2, The other end of the motor casing 2 is sequentially connected to the motor partition 5 and the rear guide vane 6 , and the motor stator 3 is fixed inside the motor casing 2 . The outer circle of the runner 9 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com