Axial force self-balance type four-screw mechanical device with gas thrust bearings

A thrust bearing and mechanical device technology, applied in the field of compressors and expanders, can solve the problems of reduced friction, low bearing capacity, large friction loss, etc., and achieve the effect of simplifying the structure of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

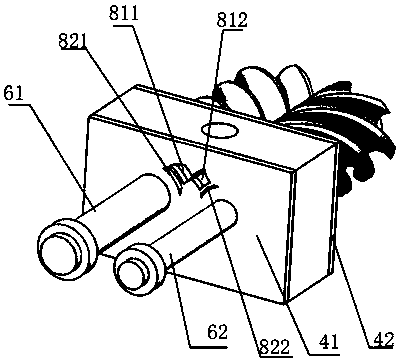

[0057] Taking the gas thrust bearing as an example, the gas static pressure thrust bearing is used, such as Figure 7 shown.

[0058] Aerostatic thrust bearings are one type of sliding bearings. When the gas enters the first working chamber 10 of the gas thrust bearing through the second exhaust hole 82, on the one hand, a layer of lubricating gas film with a certain load and rigidity will be formed in the gap between the bearing and the shaft. The supporting effect makes the shaft float in the bearing. On the other hand, the gas enters the second working chamber 11 of the gas thrust bearing through the orifice of the gas thrust bearing. The pressure increases and the flow rate decreases. The third exhaust hole 83 merges into the exhaust port 73 and is discharged together with the gas directly flowing into the exhaust port 73 , and forms a lubricating air film with a certain load and rigidity in the second working chamber 11 to bear the axial force. In the exhaust seat, the ...

Embodiment 2

[0060] Taking the gas thrust bearing as an example, the gas dynamic pressure thrust bearing is used, such as Figure 8 shown.

[0061]The dynamic pressure bearing is mainly composed of two parts: a wedge structure and a fluid lubricating film. When the gas enters the first working chamber 10 of the gas thrust bearing through the second exhaust hole 82, the gas enters the second working chamber 11 from the first working chamber 10 through the gap between the inner ring of the bearing and the first rotating shaft 61 / second rotating shaft 62 , and then flow into the exhaust port 73 through the third exhaust hole 83 under the action of the pressure difference, and be discharged together with the gas directly flowing into the exhaust port 73 . Due to the certain viscosity of the gas, the gas is compressed when it enters the reserved wedge-shaped area, and the compressed gas will generate axial pressure in the second working chamber 11 and generate supporting capacity. In the exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com