Method for producing hot rolling two-phase steel plate at 700MPa level of tensile strength

A technology of tensile strength and manufacturing method, which is applied in metal rolling, manufacturing tools, temperature control, etc., can solve the problems of unfavorable promotion, high cost, and incapability of large-scale production, so as to avoid surface wrinkling, low cost, and excellent quality. The effect of comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

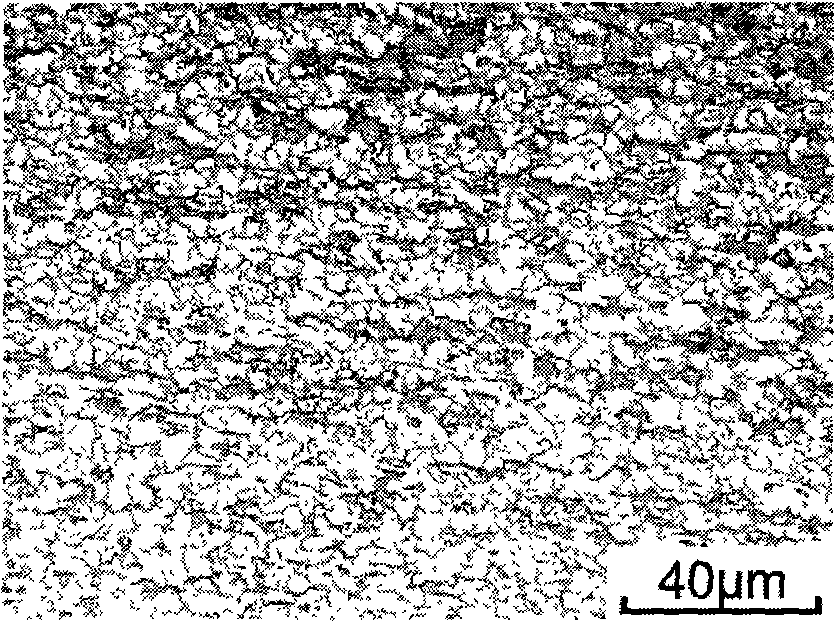

[0019] from figure 1 It can be seen that the 700MPa grade dual-phase steel plate obtained in this patent has a dual-phase structure of polygonal ferrite and martensite, wherein the white part is ferrite structure with a volume fraction of about 85%, and the gray-black part is martensite. Tensitic structure, the volume fraction is about 15%.

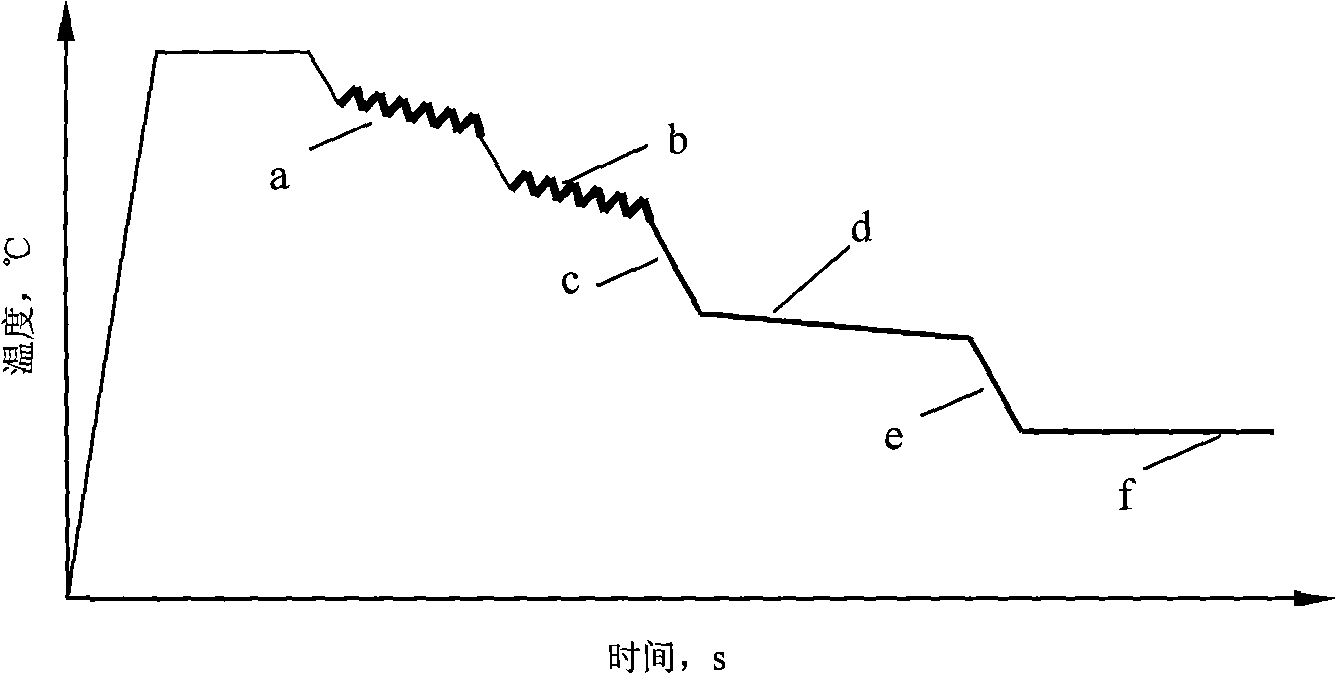

[0020] from figure 2 It can be seen that the two-stage cooling after hot rolling is an important implementation step of this patent. It mainly includes the first stage of water cooling. After a certain period of air cooling, the second stage of water cooling is carried out. After the water is cooled to a certain temperature, coiling Therefore, controlled cooling is an important guarantee for obtaining good microstructure and properties of dual-phase steel.

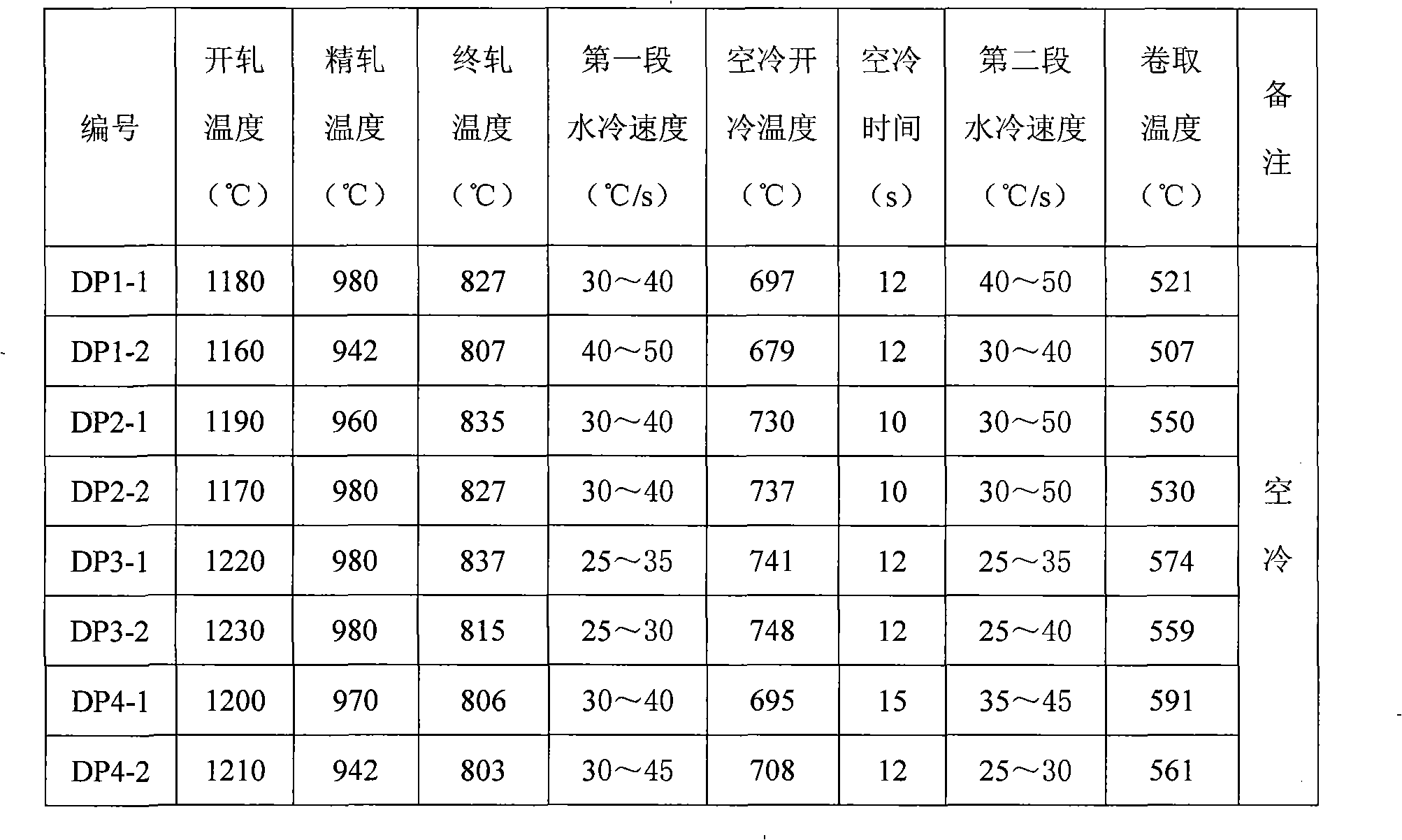

[0021] The steel with the chemical composition shown in Table 1 is selected as the raw material, and the blank size is 40mm (thickness) × 80mm (width) × 100mm (length). The contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com