Steel adapting to high deformation and punching and used for high-surface-quality aluminum-coated substrates and production method thereof

A technology of stamping processing and production method, applied in the field of high surface quality aluminum-clad substrate steel and its production, can solve the problems of insufficient plastic deformation ability, difficulty in meeting large deformation requirements, poor steel-aluminum bonding performance, etc., and achieve excellent plasticity. Deformation ability, excellent steel-aluminum interface bonding performance, uniform deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

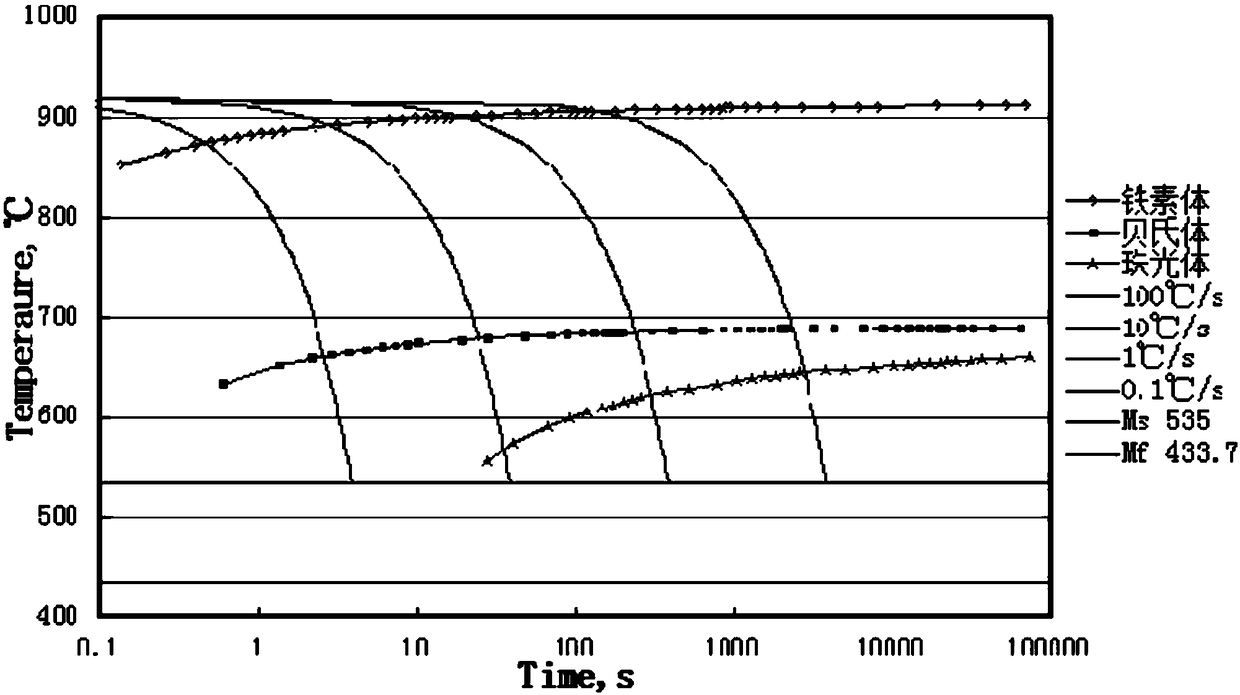

Image

Examples

Embodiment 1

[0054] According to the steel chemical composition requirements of the present invention, steelmaking is carried out in a 500kg vacuum induction furnace, and the obtained chemical composition is shown in Table 1, and cast into a 100kg steel ingot. 600°C.

[0055] The mechanical properties of the steel examples of the present invention are shown in Table 2. The composition, production process and performance were compared with similar steel grades. in,

[0056] Contrast steel 1 is Chinese patent CN101514426A "Steel with low yield point for anti-seismic buildings with a yield strength of 100 MPa and its production method"; the content of Si and Al is relatively high, and it does not contain O;

[0057] Contrast steel 2 is the Chinese patent CN101775535A "160MPa level earthquake-resistant low-yield point steel, steel plate and its manufacturing method", which has a high Al content and does not contain O;

[0058] Comparative steel 3 is Chinese patent CN101525720 "a new type of...

Embodiment 2

[0064] According to the composition requirements of the present invention, the steel of the present invention is smelted on a 500kg vacuum induction furnace in a laboratory. The chemical composition is shown in Table 1. The billet heating temperature is 1200°C, the final rolling temperature is 820-860°C, and after rolling, it is water-cooled to 540-600°C for coiling or air-cooled to room temperature. Rolling thickness 2-8mm. The mechanical properties are shown in Table 2.

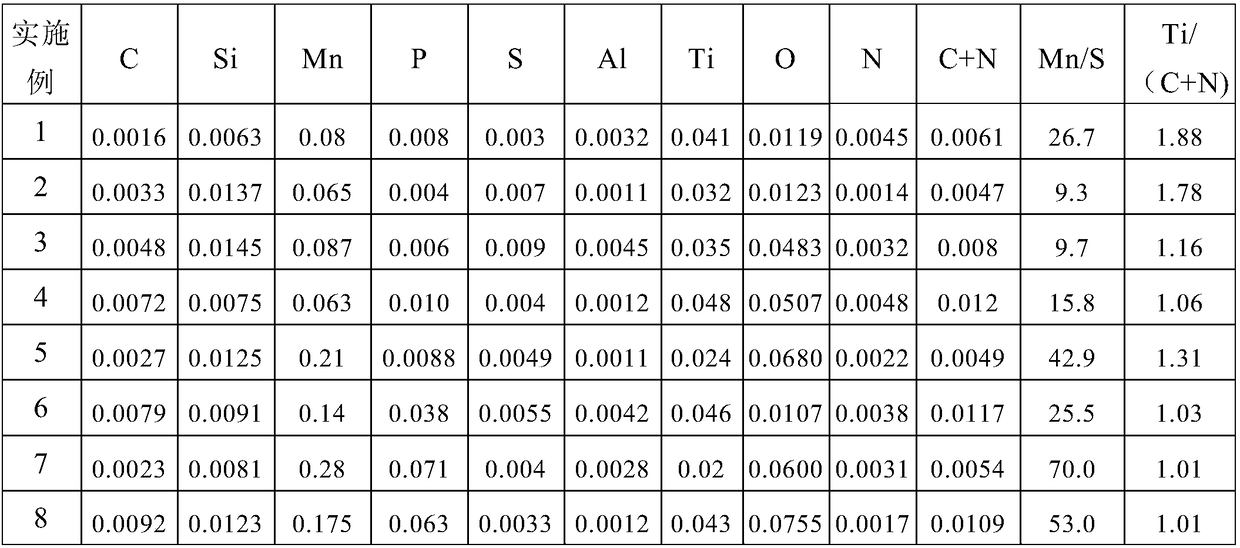

[0065] Table 1 steel embodiment of the present invention - chemical composition unit: weight percent

[0066]

[0067] Table 2 Steel Examples of the Invention - Mechanical and Aluminum-clad Properties

[0068]

[0069] It can be seen from Table 2 that the steel of the present invention has stable yield strength, and under different rolling processes, the tensile strength of steel plates of various specifications is all between 280-380MPa, and has very high elongation. It is superior to the compari...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com