Pickle sheet for 400MPa-level automobile structure and production method of pickle sheet

A technology of automobile structure and production method, applied in the field of steel rolling, can solve the problem of high cost, achieve the effects of low production cost, solving waste acid pollution and significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

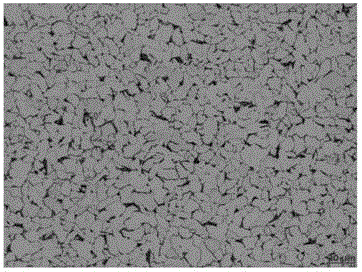

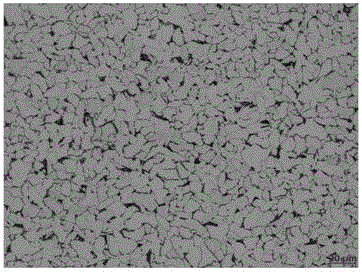

Image

Examples

Embodiment 1

[0026] In terms of weight percentage, the chemical composition of the billet is: C: 0.07%, Si: 0.03%, Mn: 1.10%, P: 0.011%, S: 0.003%, Als: 0.036%, and the rest is Fe and unavoidable impurities.

[0027] Its production process is: billet → hot rolling → laminar cooling → coiling → leveling → pickling → oiling → finished product. After being heated at 1200°C, the 220mm thick steel billet is rough rolled into a 35mm thick intermediate billet through two reversible rough rolling mills for 6 passes. The rough rolling reduction rate is 84.1%. A 2.8mm thick steel coil was rolled by 7 passes, the finishing rolling reduction rate was 92.0%, and the final rolling temperature was 850°C. After the steel coil is cooled by laminar flow, it enters the coiler to obtain the strip steel, and the coiling temperature is 580°C. After the temperature of the steel coil is lower than 50 degrees, the steel coil is transported to the leveling unit for leveling, and the leveling elongation rate is 1.2...

Embodiment 2

[0030] In terms of weight percentage, the chemical composition of the billet is: C: 0.08%, Si: 0.03%, Mn: 1.08%, P: 0.012%, S: 0.005%, Als: 0.042%, and the rest is Fe and unavoidable impurities.

[0031] Its production process is: billet → hot rolling → laminar cooling → coiling → leveling → pickling → oiling → finished product. After being heated at 1200°C, the 220mm thick steel billet is rough rolled into a 40mm thick intermediate billet through two reversible rough rolling mills for 6 passes. The rough rolling reduction rate is 81.8%. The 3.5mm-thick steel coil was rolled by 7 passes, the final rolling reduction rate was 91.3%, and the final rolling temperature was 850°C. After the steel coil is cooled by laminar flow, it enters the coiler to obtain the strip steel, and the coiling temperature is 590°C. After the temperature of the steel coil is lower than 50 degrees, the steel coil is transported to the leveling unit for leveling, and the leveling elongation rate is 1.2%....

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com