Punching machine and punching method thereof for printed circuit board

A technology of printed circuit boards and punching machines, which is applied in manipulators, manufacturing tools, metal processing, etc. It can solve the problems of large mobile frame area, inconvenient clamping, and reduced speed, so as to achieve small motion inertia and low maintenance costs. Low, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

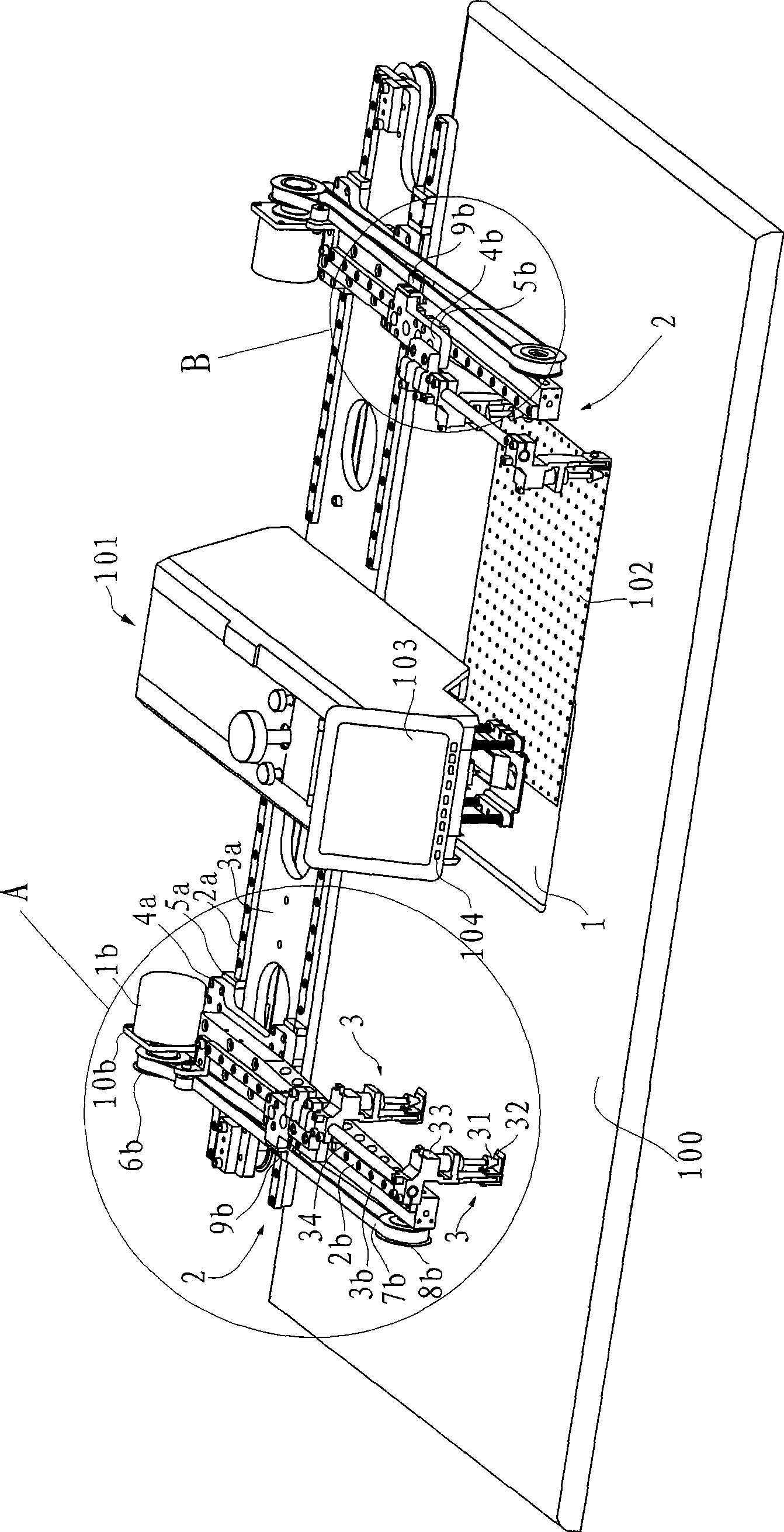

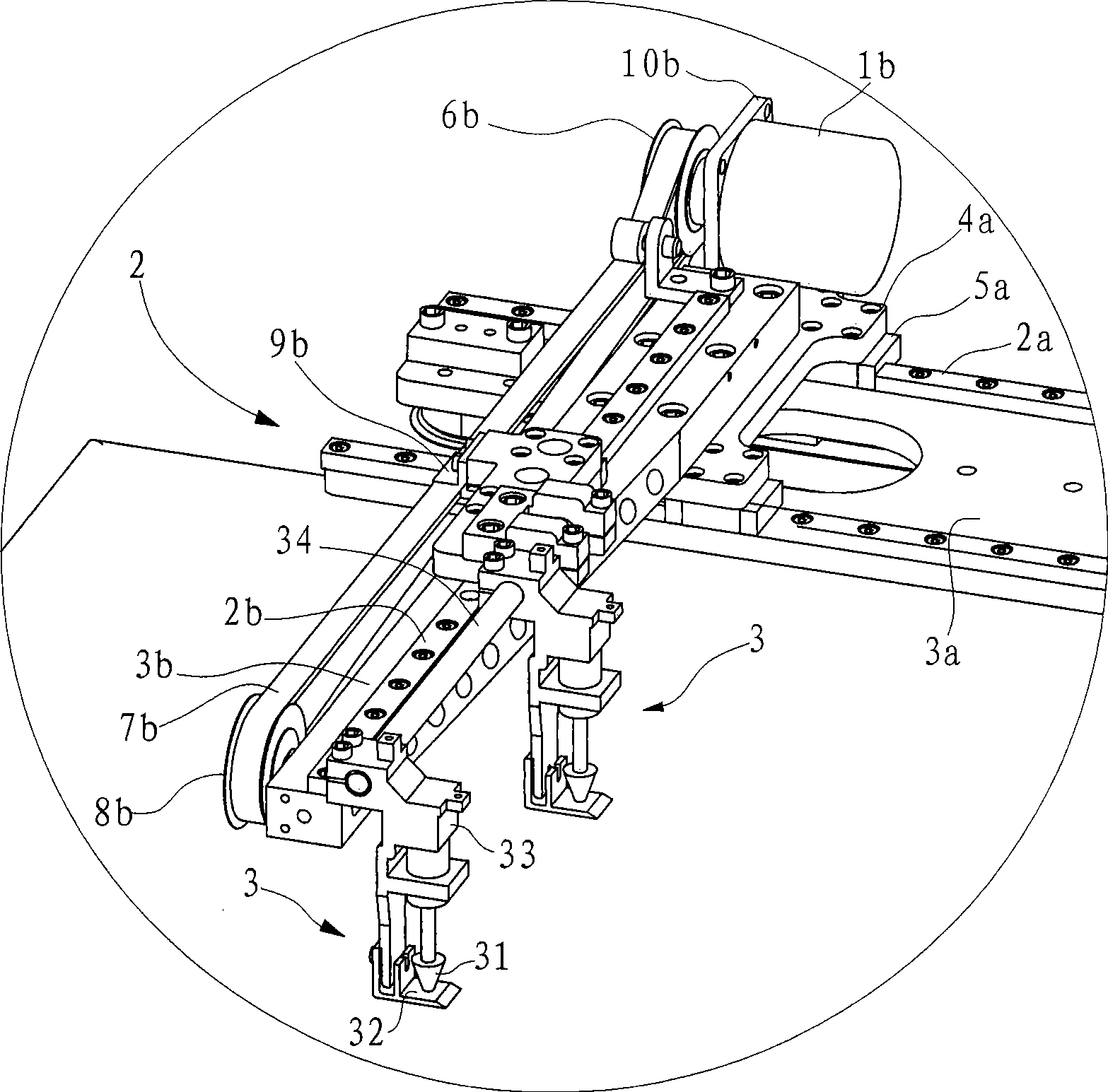

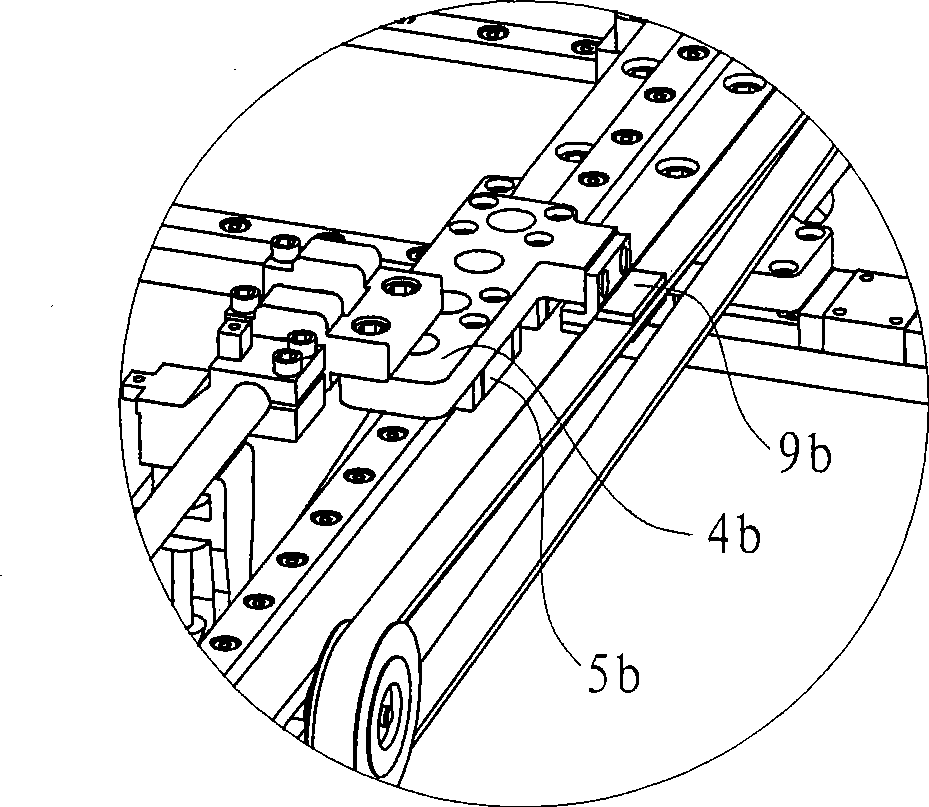

[0053] Example: as Figure 1 to Figure 4 As shown, the printed circuit board punching machine in this embodiment includes a machine head 101, a worktable 100, a mobile table 1, a control device (not shown in the figure) and a mobile manipulator 2, and the machine head 101 is provided with punching holes The mechanism, the pressing device, the display panel 103 and the input button 104, the punching mechanism is used to punch holes on the printed circuit board 102, in this embodiment, the punch 9 and the concave mould structure are used. The pressing device can press the printed circuit board 102 against the mobile table 1 to make the printed circuit board 102 move with the mobile table 1 . In this embodiment, a presser foot 4 is used.

[0054] The moving table 1 is used for fine-tuning the position of the printed circuit board 102 in a small range, and is located in the center of the work table 100, and has a transverse driving mechanism and a longitudinal driving mechanism (b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com