Adjustable clamping mobile manipulator

A technology for moving manipulators and manipulators, applied in the field of manipulators, can solve the problems of long time for equipment to stop running, reduced equipment use efficiency, long replacement time, etc., and achieves the effect of short stopping time, short replacement time and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

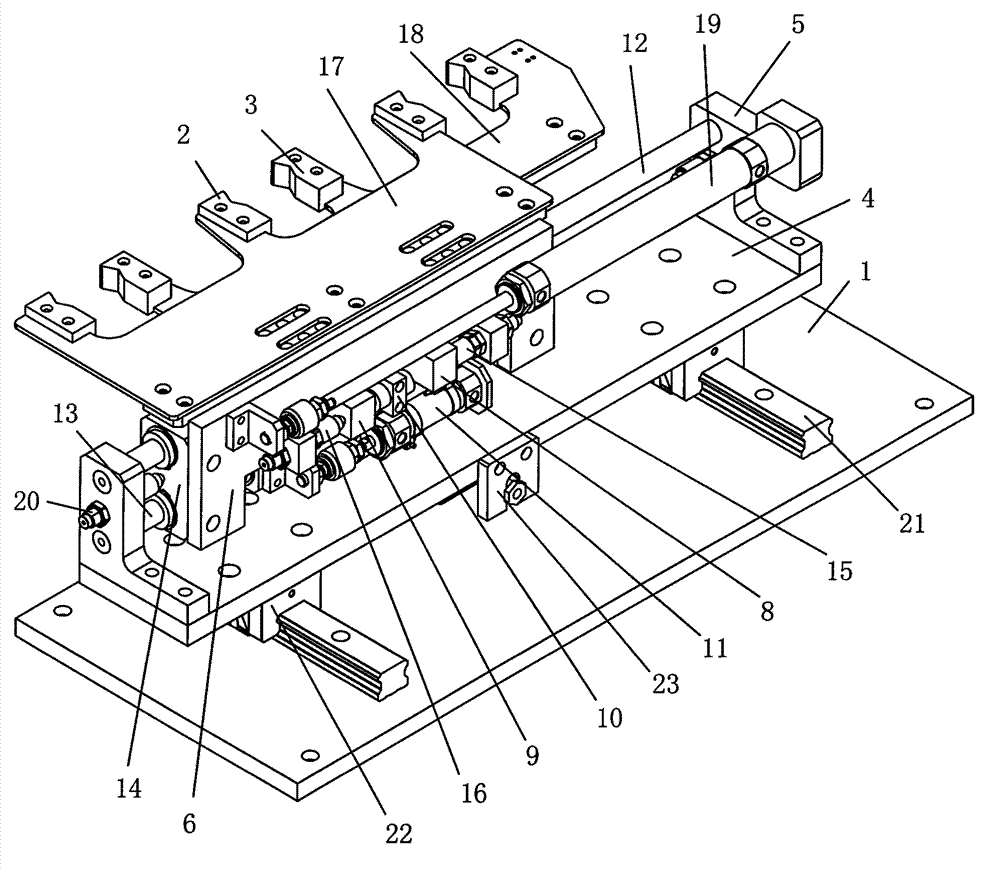

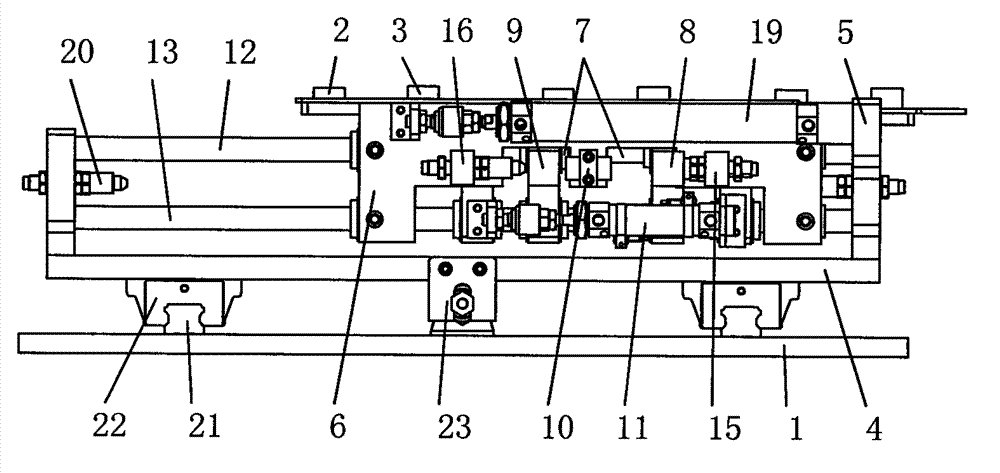

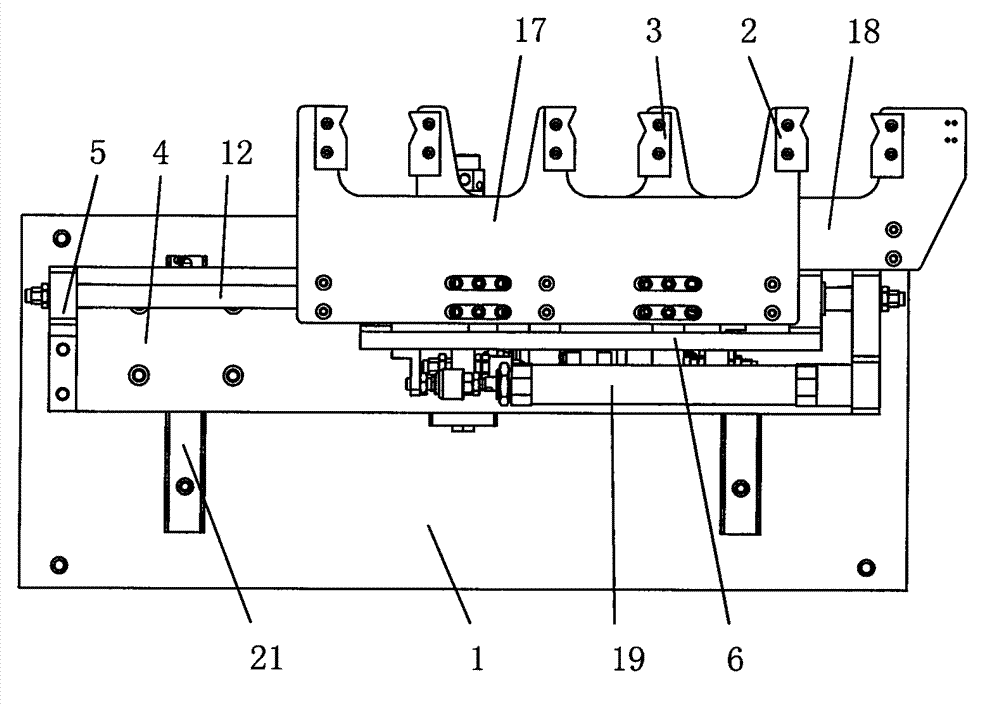

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] refer to Figure 1 to Figure 4 , an adjustable clamping mobile manipulator, including a workbench 1 and a manipulator set on the workbench 1, the manipulator is composed of at least one pair of symmetrical upper manipulator 2 and lower manipulator 3, the workbench 1 A bracket plate 4 is arranged horizontally on the upper side, and the bracket plate 4 is driven by a longitudinal drive mechanism to slide longitudinally along the workbench 1. Supports 5 are vertically arranged on both sides of the support plate 4, and the two supports 5 A guide rod is arranged horizontally between the guide rods, and a slide plate 6 driven by a lateral movement mechanism to move laterally along the guide rods is slid on the guide rods. The middle part of the slide plate 6 is provided with a positioning groove 7, and a positioning groove 7 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com