Automatic rail changing walking chassis of facility leaf vegetable harvesting robot and rail changing method

A walking chassis and robot technology, which is applied in the field of agricultural robots, can solve the problems of high cost, complicated on-track walking and changing rails, and inefficient track changing, and achieves the effects of small footprint, high degree of automation, and compact vehicle body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

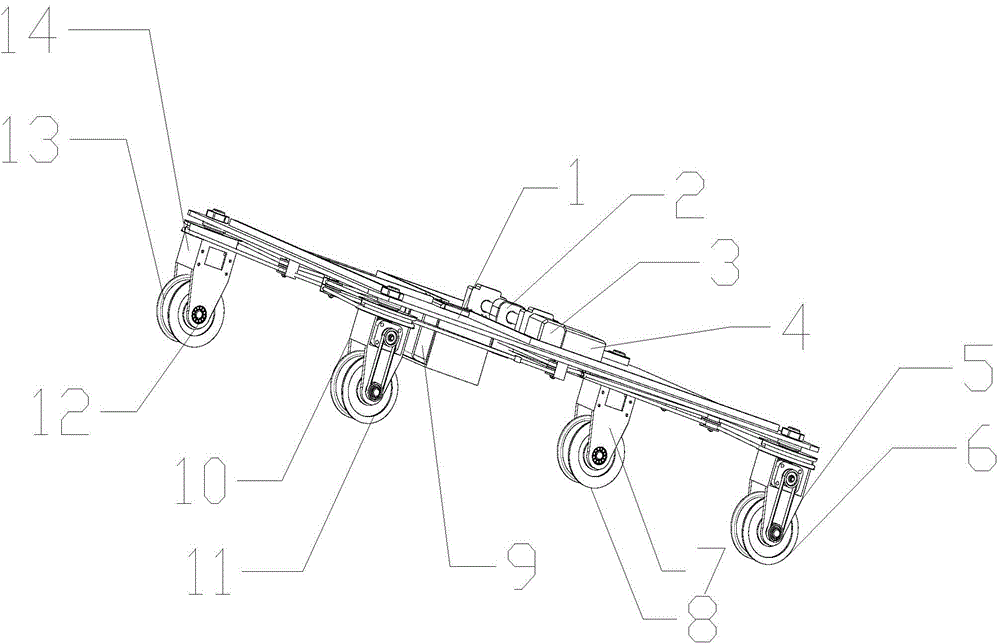

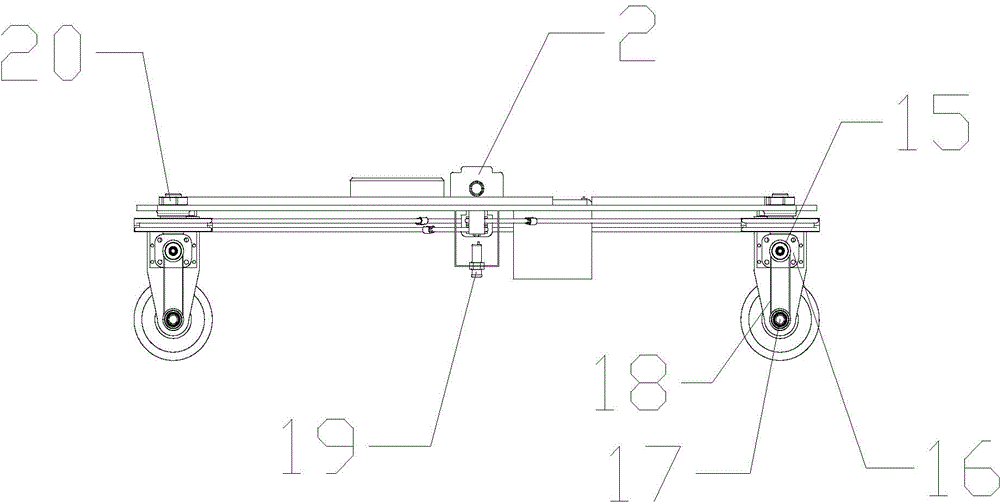

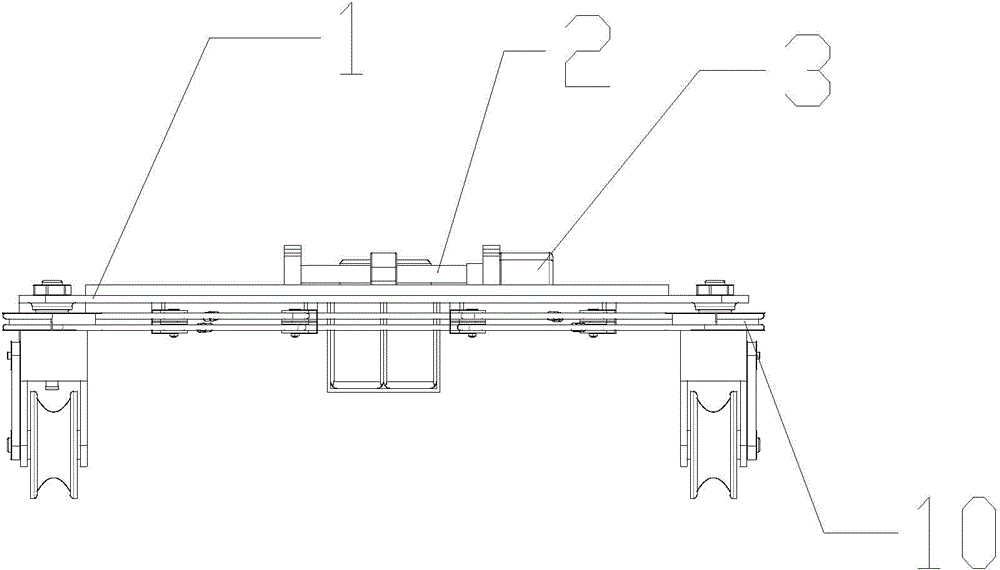

[0028] Below in conjunction with accompanying drawing, the patent of the present invention is further described. The automatic track-changing walking chassis of a facility leaf vegetable harvesting robot described in the present invention, such as figure 1 , 2, 3, 4 shown. The moving mechanism comprises traveling wheels, a traveling wheel fixing frame, a driving device, fixing bolts and lock nuts (20). The traveling wheel fixed mount is a universal wheel swivel frame, the top of the traveling wheel fixed mount is a cylindrical platform and a hollow frame, and the four traveling wheel fixed mounts are respectively fixed on the railcar chassis ( On the four corners of 1), they are respectively called traveling wheel fixed frames 1-4; the described traveling wheels adopt double-sided rail wheels, and the traveling wheels are respectively fixedly placed in the middle of the traveling wheel fixed frames, which are respectively called traveling wheels 1-4 ; Described drive unit i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com