Smelting preparation method of high-purity high-silicon manganese-silicon alloy

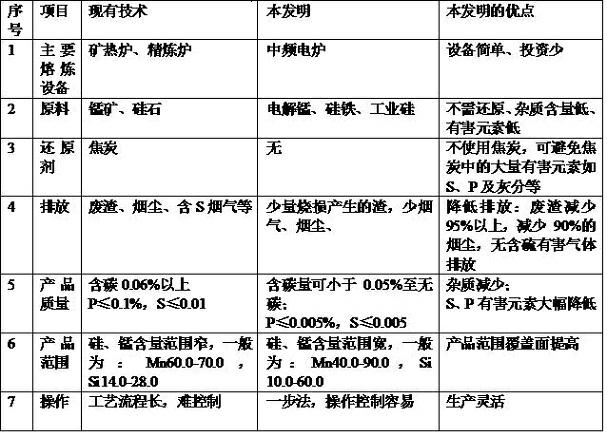

A high-silicon-manganese-silicon-silicon alloy technology, which is applied in the field of smelting and preparation of high-purity high-silicon-manganese-silicon alloys, can solve the problems of complicated smelting methods, high content of harmful impurity elements, and high difficulty in element content matching control, achieving significant economic benefits and social benefits, low content of harmful impurity elements, and fast smelting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Smelting FeMn64Si27 alloy with electrolytic manganese, ferrosilicon and industrial silicon:

[0047] Ingredients: electrolytic manganese 640Kg, FeSi75-A 360Kg, alloy block particle size 2~15cm;

[0048] Slag material: 5Kg each of wollastonite and lime, mix well;

[0049] Equipment: a medium frequency induction furnace with a nominal capacity of 1000Kg and a frequency of 1kHz, using a neutral alumina crucible, the power supply method is three-phase power supply, and the overall stirring method;

[0050] Melting process: first add slagging material, mix electrolytic manganese and ferrosilicon into the furnace, and control the temperature at 1380~1400°C after energizing and heating up to melt, determine the alloy composition as Mn63%, Si26.5%, add 10Kg electrolytic Manganese and 6Kg of ferrosilicon are melted and kept under electromagnetic stirring, the temperature is raised to 1420°C, the dross is removed, and poured into a metal mold to form a block-shaped high-silicon-...

Embodiment 2

[0052] Melting Mn60Si40 alloy with electrolytic manganese and industrial silicon:

[0053] Ingredients: electrolytic manganese 60Kg, industrial silicon 40Kg;

[0054] Slag material: wollastonite 0.7Kg, lime 0.3Kg, mix well;

[0055] Equipment: a medium frequency induction furnace with a nominal capacity of 100Kg and a frequency of 1kHz, using a quartz sand crucible, the power supply method is two-phase power supply, and the overall stirring method;

[0056] Melting process: first add slagging material, put electrolytic manganese into the furnace, turn on the electricity to heat up and melt, control the temperature at 1450°C, add industrial silicon in two batches, determine the alloy composition after melting as Mn55%, Si38%, add 5Kg Electrolytic manganese and 2Kg of industrial silicon are melted and kept under electromagnetic stirring, the temperature is lowered to 1400°C, the scum is removed, and poured into a metal mold to form a block-shaped high-silicon-manganese-silicon ...

Embodiment 3

[0058] Smelting FeMn64Si18 alloy with electrolytic manganese and ferrosilicon:

[0059] Ingredients: electrolytic manganese 130Kg, FeSi75-A 70Kg, alloy block particle size 2~15cm;

[0060] Slag material: wollastonite 0.6Kg, lime 1.4Kg, mix well;

[0061] Equipment: a medium-frequency induction furnace with a nominal capacity of 200Kg and a frequency of 500Hz, using a magnesia crucible, the power supply method is three-phase power supply, and the overall stirring method;

[0062] Melting process: first add slagging material, mix electrolytic manganese and ferrosilicon into the furnace, and control the temperature at 1300°C after heating up and melting. After melting, the alloy composition is determined to be Mn63.5%, Si17.2%, and additional After 1Kg of electrolytic manganese and 3Kg of ferrosilicon, the furnace temperature was raised to 1320°C, the dross was removed, and poured into a metal mold to form a block-shaped high-silicon-manganese-silicon alloy; the composition of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com