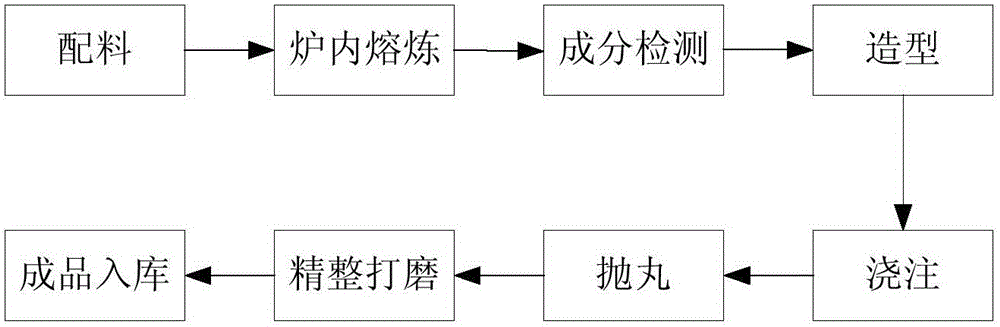

Cast piece processing technology

A processing technology and casting technology, applied in the field of casting processing, can solve problems such as unstable casting quality, high labor intensity of workers, complex influencing factors, etc., and achieve the effects of fast melting speed, convenient melting, and flexible and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A casting process, comprising the steps of:

[0024] 1) Ingredients: Select 750kg of smelted pig iron, 150kg of scrap steel, and 100kg of recycle materials, and stir and mix them.

[0025] 2) Smelting in the furnace: Put the prepared charge into a 2-ton intermediate frequency induction furnace to smelt the charge into molten iron. The input voltage of the medium frequency induction furnace is 380V, the output voltage is 750V, and the output frequency is 10kHz. The smelting time is 60 minutes, the smelting temperature is 1350°C, and the exhaust gas after smelting in the furnace is dust-collected by cloth bags.

[0026] 3) Composition detection: a molten iron composition analyzer is installed in front of the furnace to detect and adjust the composition of the molten iron.

[0027] 4) Molding: First put molding sand into the empty sand box, then put the foam plastic gasification mold into the sand box and make it stable; then fill the molding sand layer by layer accordin...

Embodiment 2

[0033] A casting process, comprising the steps of:

[0034] 1) Ingredients: Select 850kg of smelted pig iron, 100kg of steel scrap, and 50kg of recycled material, and stir and mix.

[0035] 2) Smelting in the furnace: Put the prepared charge into a 2-ton intermediate frequency induction furnace to smelt the charge into molten iron. The input voltage of the medium frequency induction furnace is 380V, the output voltage is 750V, and the output frequency is 10kHz. The smelting time is 30 minutes, the smelting temperature is 1500°C, and the waste gas after smelting in the furnace is dust-collected by cloth bags.

[0036] 3) Composition detection: a molten iron composition analyzer is installed in front of the furnace to detect and adjust the composition of the molten iron.

[0037] 4) Molding: First put molding sand into the empty sand box, then put the foam plastic gasification mold into the sand box and make it stable; then fill the molding sand layer by layer according to the...

Embodiment 3

[0043] A casting process, comprising the steps of:

[0044] 1) Ingredients: Select 800kg of smelted pig iron, 100kg of scrap steel, and 100kg of recycled materials, and stir and mix them.

[0045] 2) Smelting in the furnace: Put the prepared charge into a 2-ton intermediate frequency induction furnace to smelt the charge into molten iron. The input voltage of the medium frequency induction furnace is 380V, the output voltage is 750V, and the output frequency is 10kHz. The smelting time is 45 minutes, the smelting temperature is 1450°C, and the waste gas after smelting in the furnace is dust-collected by cloth bags.

[0046] 3) Composition detection: a molten iron composition analyzer is installed in front of the furnace to detect and adjust the composition of the molten iron.

[0047] 4) Molding: First put molding sand into the empty sand box, then put the foam plastic gasification mold into the sand box and make it stable; then fill the molding sand layer by layer according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com