Flame space of pure oxygen combustion kiln, pure oxygen combustion kiln and method for preparing glass liquid

An all-oxygen combustion and space technology, which is applied in glass production, glass furnace equipment, glass manufacturing equipment, etc., can solve problems such as accelerating the erosion of alkali vapor in the kiln to the roof tiles and shortening the life of the kiln.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

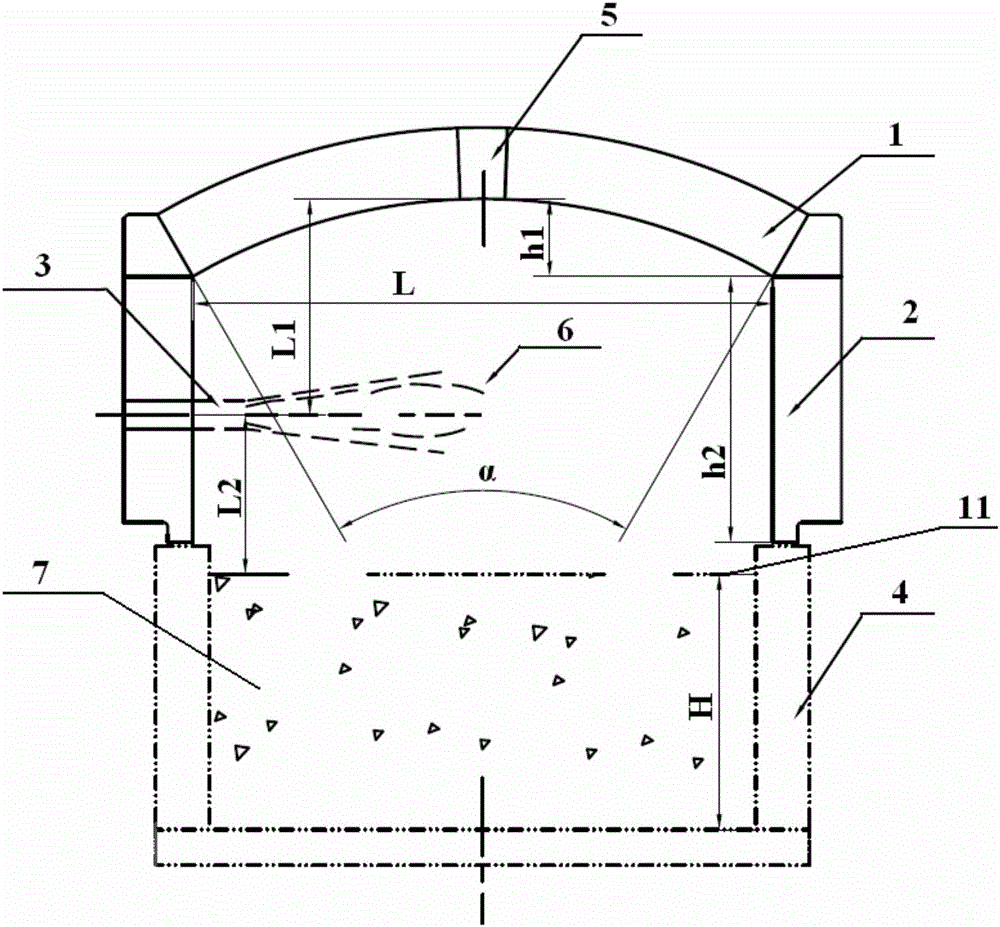

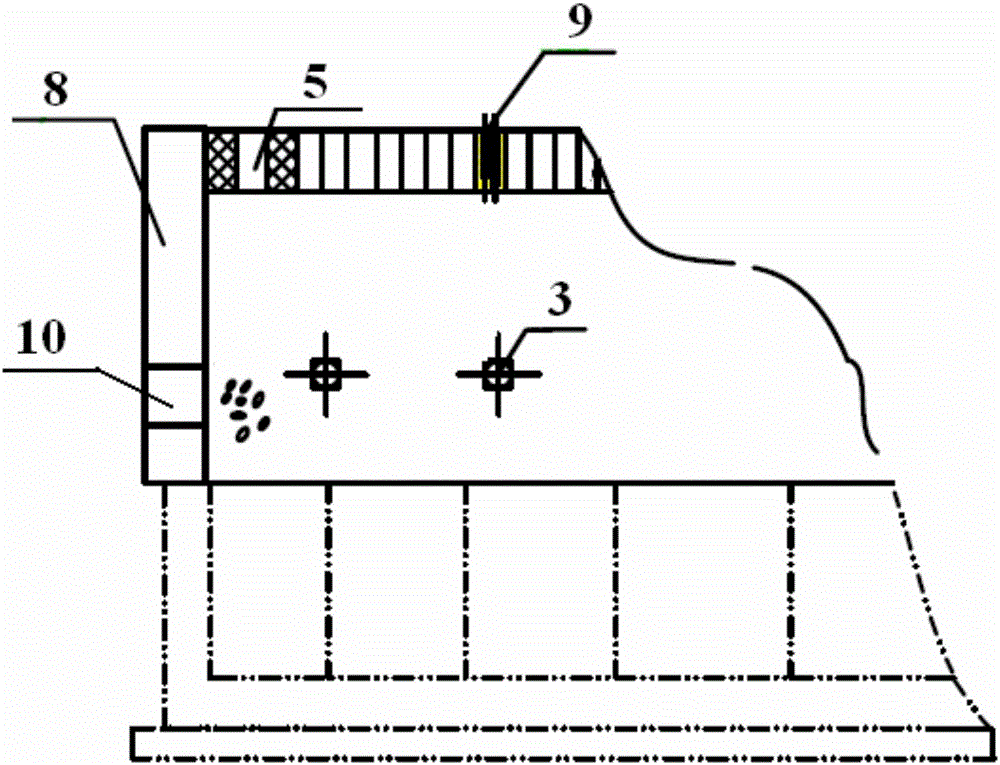

[0049] Such as Figure 1-2 As shown, the flame space structure of this embodiment is used in an oxy-combustion kiln with a melting amount of 10 tons / day and natural gas as fuel. The flame space is matched with the melting pool 4 located below it, and the parapet 2 is provided with a burner 3, the burners 3 are symmetrically arranged in pairs, and form a flame 6 after burning during combustion. There is a liquid level scale line 11 on the pool wall, the flue gas outlet 5 is set on the top of the large wall 1 above the kiln feeding area, the feeding port 10 is located on the front gable 8, and the feeding machine is set on the front gable 8 when feeding. The feeding port 10 on the top is input with glass raw material, the material of the hole brick of the flue gas outlet 5 is 33# fused zirconia corundum brick, the material of the top brick of Dapan 1 is 33# fused zirconia corundum brick, and the material of the breast wall brick is α-β corundum brick; among them, h1 / L=1:8.3, (h...

Embodiment 2

[0053] Such as Figure 1-2 As shown, the flame space structure of this embodiment is used in an oxy-combustion kiln with a melting amount of 10 tons / day and natural gas as fuel. The flame space is matched with the melting pool 4 located below it, and the parapet 2 is provided with a burner 3, the burners 3 are symmetrically arranged in pairs, and form a flame 6 after burning during combustion. There is a liquid level scale line 11 on the pool wall, the flue gas outlet 5 is set on the top of the large wall 1 above the kiln feeding area, the feeding port 10 is located on the front gable 8, and the feeding machine is set on the front gable 8 when feeding. The feeding port 10 on the top is used to input glass raw materials, the material of the hole bricks of the flue gas outlet 5 is 36# fused zirconia corundum bricks, the material of the top bricks of the large wall 1 is 36# fused zirconia corundum bricks, and the material of the breast wall bricks is α-β corundum brick; among th...

Embodiment 3

[0057] Such as Figure 1-2 As shown, the flame space structure of this embodiment is used in an oxy-combustion kiln with a melting amount of 10 tons / day and natural gas as fuel. The flame space is matched with the melting pool 4 located below it, and the parapet 2 is provided with a burner 3, the burners 3 are symmetrically arranged in pairs, and form a flame 6 after burning during combustion. There is a liquid level scale line 11 on the pool wall, the flue gas outlet 5 is set on the top of the large wall 1 above the kiln feeding area, the feeding port 10 is located on the front gable 8, and the feeding machine is set on the front gable 8 when feeding. The feeding port 10 on the top is put into glass raw material, the material of the hole brick of the flue gas outlet 5 is 41# fused zirconia corundum brick, the material of the crown brick of Dapan 1 is α-β corundum brick, and the material of breast wall brick is β corundum brick Brick; among them, h1 / L=1:7.8, (h1+h2) / H=1.7:1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com