Light gauge aluminum foil woolen produced with AL-Ti-C wire refiner and preparation method

A double-zero aluminum foil, al-ti-c technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems that the alloy production process cannot meet the requirements and the alloy production process has high requirements, and achieve the reduction of pinholes Increase the probability, uniform and delicate color, reduce the effect of hard spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

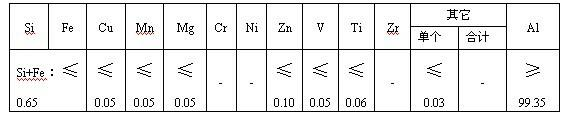

[0035] A kind of Al-Ti-C wire refiner is used to produce double-zero aluminum foil wool, and the mass fraction of alloy elements in the aluminum foil wool is as follows:

[0036] Its Fe:Si is between 4.3~5.3:1.

[0037] Among them, the preferred scheme is: Fe: 0.35~0.45%; Si: 0.08~0.12%

[0038] Its preparation includes the following process flow: material preparation→batching→feeding→melting→stirring→primary refining in smelting furnace (powder injection refining with argon gas)→slag removal→sampling→component adjustment→secondary refining in smelting furnace (using carbon tetrachloride Refining)→slag removal→converter→one-time refining in static furnace (refining with carbon tetrachloride)→intensified refining in static furnace (argon refining every 2 hours)→add Al-Ti-C wire master alloy fine online Chemical agent→Ar on-line degassing→Filter box dual-channel dual-stage foam ceramic filter plate filtration (the upper filter plate mesh is 30PPI and the lower filter plate mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com