Three-level aging heat treatment process for nanometer magnesium alloy

An aging heat treatment, three-stage aging technology, applied in the field of nanomaterial heat treatment, to achieve the effect of ensuring peak aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

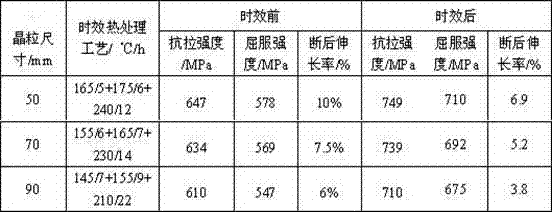

[0018] Nano-magnesium alloy with an average grain size of 50nm (alloy composition (w%): Gd: 8%, Y: 4%, Zr: 0.5%, the rest is Mg and non-removable impurity elements) at 165 ° C The first-stage aging treatment, the aging time is 5h, and then the nano-magnesium alloy after the first-stage aging treatment is subjected to the second-stage aging treatment at 175°C, and the aging time is 6h, and finally the alloy after the second-stage aging is subjected to three-stage aging at 240°C. Level aging treatment, aging time 12h. According to GB / T228-2002, the mechanical properties of the aged magnesium alloy were tested and compared with the pre-aging alloy. The results showed that compared with the unaged nano-magnesium alloy, the tensile strength of the aged magnesium alloy at room temperature was increased by 102MPa, and the yield strength was increased by 132MPa. The tensile strength is up to 749MPa, and the yield strength is up to 710MPa. The specific results are shown in Table 1.

Embodiment 2

[0020] Nano-magnesium alloy with an average grain size of 70nm (alloy composition (w%): Gd: 10%, Y: 6%, Zr: 0.4%, the rest is Mg and non-removable impurity elements) at 155 ° C The first-stage aging treatment, the aging time is 6h, then the nano-magnesium alloy after the first-stage aging treatment is subjected to the second-stage aging treatment at 165°C, and the aging time is 7h, and finally the alloy after the second-stage aging is subjected to three-stage aging at 230°C. Level aging treatment, aging time 14h. According to GB / T228-2002, the mechanical properties of the aged magnesium alloy were tested and compared with the pre-aging alloy. The results showed that, compared with the unaged nano-magnesium alloy, the room temperature tensile strength of the aged magnesium alloy was increased by 105MPa, and the yield strength was increased by 123MPa. The tensile strength is up to 739MPa, and the yield strength is up to 692MPa. The specific results are shown in Table 1.

Embodiment 3

[0022] The nano-magnesium alloy with an average grain size of 90nm (alloy composition (w%): 12%, Y: 3%, Zr: 0.7%, the rest is Mg and non-removable impurity elements) at 145 ° C for the first First-level aging treatment, aging time 7h, then the nano-magnesium alloy after the first-level aging treatment is subjected to second-level aging treatment at 155°C, and the aging time is 9h, and finally the alloy after the second-level aging treatment is subjected to third-level aging at 210°C Treatment, aging time 22h. According to GB / T228-2002, the mechanical properties of the aged magnesium alloy were tested and compared with the pre-aging alloy. The results showed that compared with the unaged nano-magnesium alloy, the room temperature tensile strength of the aged magnesium alloy was increased by 100MPa, and the yield strength was increased by 128MPa. The tensile strength is up to 710MPa, and the yield strength is up to 675MPa. The specific results are shown in Table 1.

[0023]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com