Method for preparing high-strength high-toughness magnesium alloy plate strip

A magnesium alloy plate and high toughness technology, applied in the field of magnesium alloy processing, can solve the problems of strength and hardness limiting the use range, affecting the forming ability, increasing production costs, etc., and achieving good industrial application prospects, convenient operation, and energy saving effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

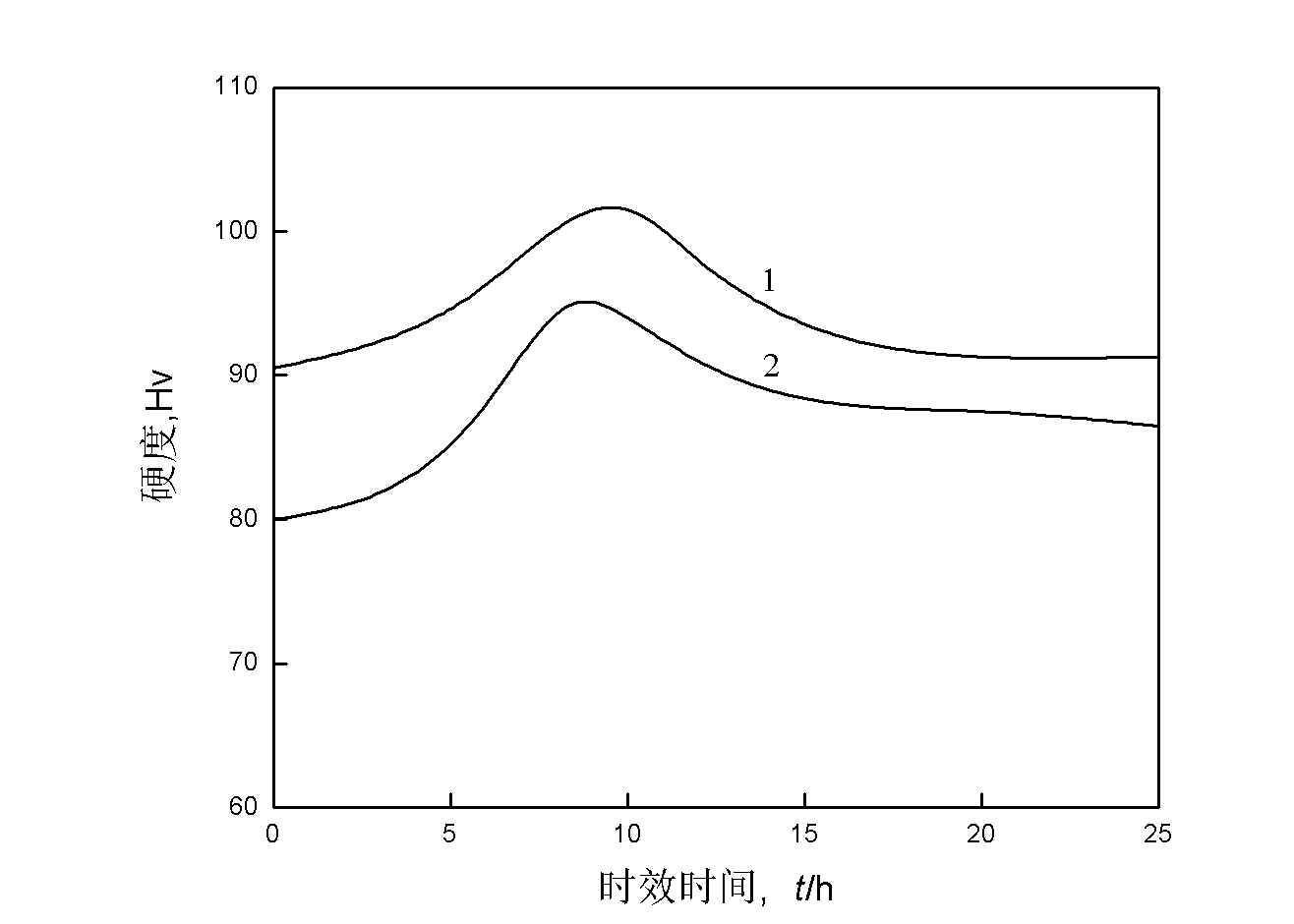

[0035] The AZ91 magnesium alloy with thermal deformation was cold rolled at room temperature, deformed to 8%, and artificially aged at 200 °C. attached by figure 1 It can be seen that the best aging time of the magnesium alloy treated by the process of the present invention is 8-10 hours, and the highest hardness can reach 102Hv, which is nearly 10% higher than that of the traditional direct aging treatment after thermal deformation. After testing, its compressive strength reaches 468MPa, and its maximum compression ratio reaches 13.8%.

Embodiment 2

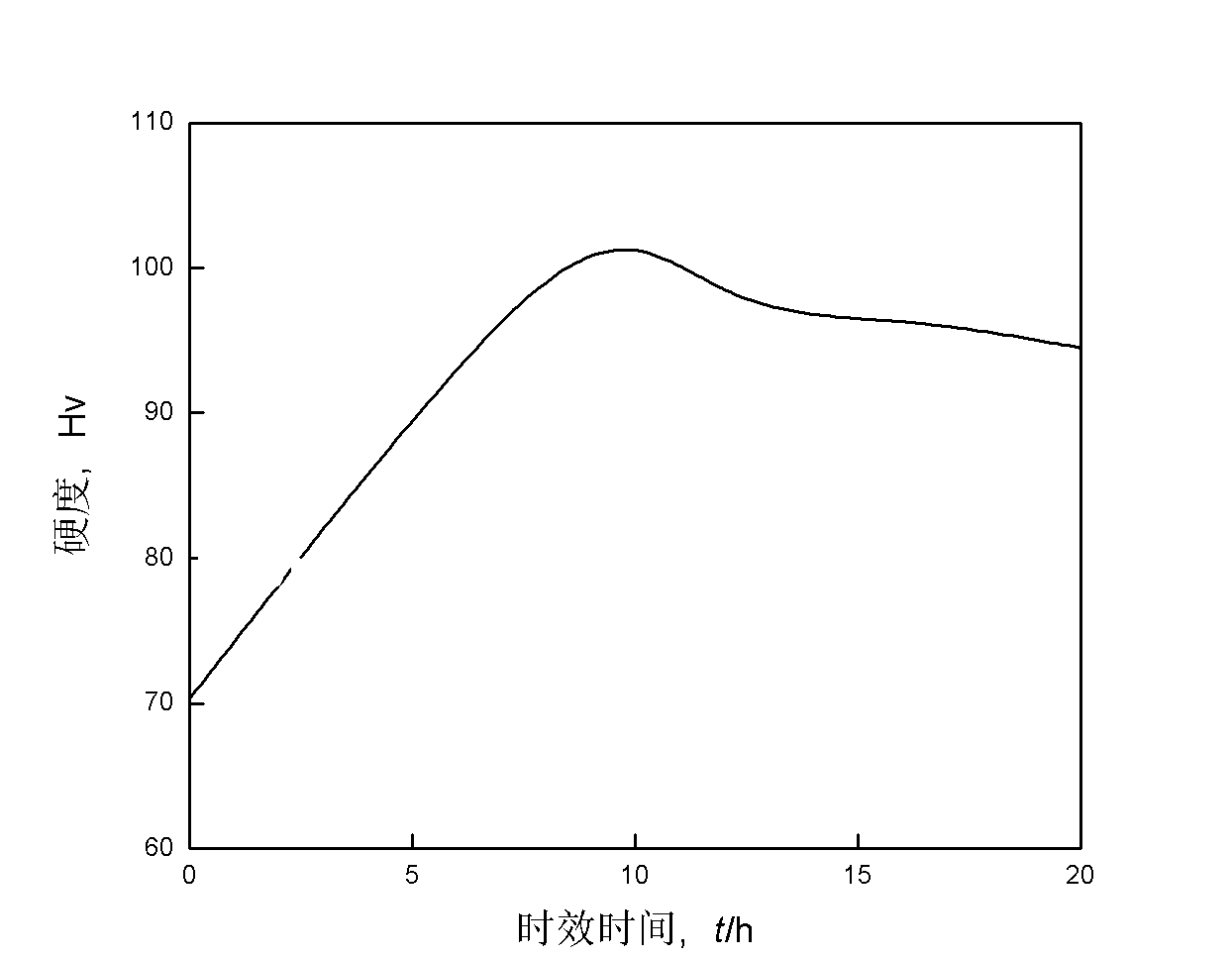

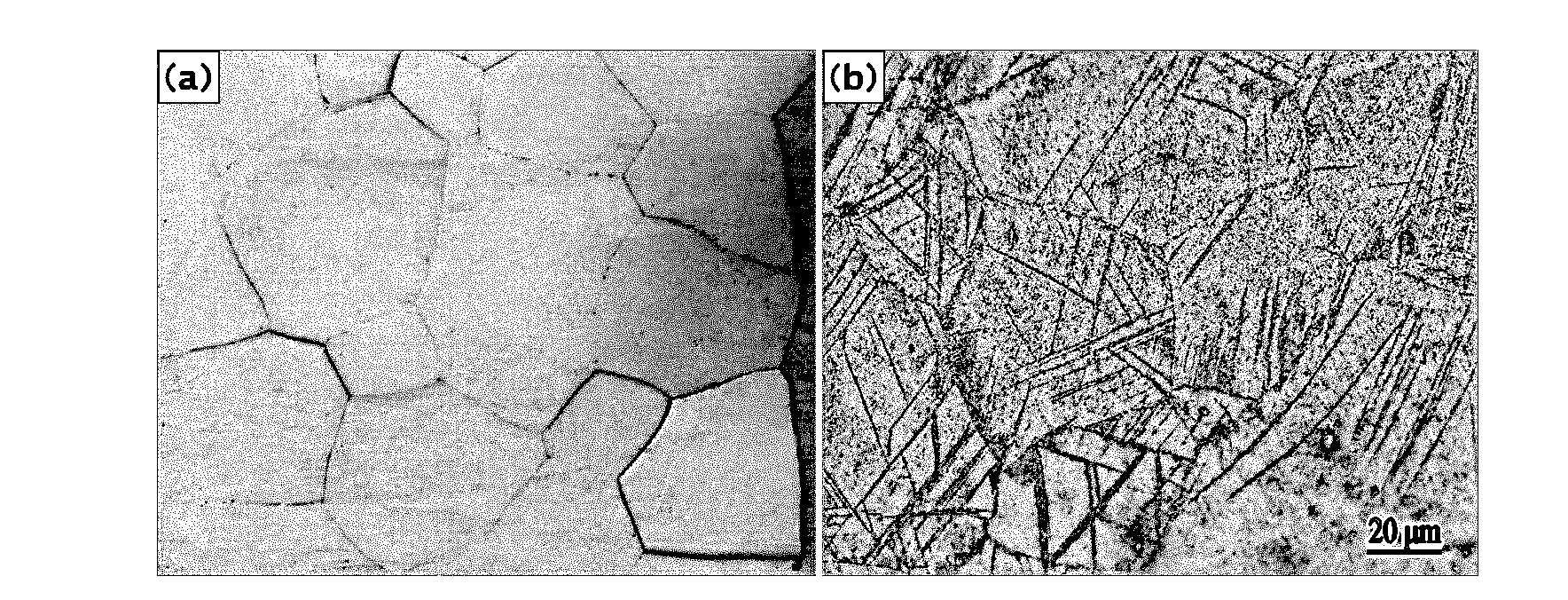

[0037] Heat the AZ91 magnesium alloy with heat-transformed form in a furnace and heat it to 430°C for 4 hours, then quench it with water, cold roll it to 8% at room temperature, and place it at 200°C for artificial aging. attached by figure 2 It can be seen that the best aging time is 10 hours, and the hardness can reach 101Hv at this time. attached by image 3 It can be seen that this high hardness is mainly due to the large number of twins produced during cold deformation and the large number of fine and dispersed granular second phases that are preferentially precipitated from within and near the twins. It can be seen from Table 1 that the compressive strength and maximum compressibility of the magnesium alloy specimens at this time are 472MPa and 20.2%, respectively, which are greatly improved compared with 413MPa and 14.3% treated by the current method.

Embodiment 3

[0039] Put the thermally deformed AZ91 magnesium alloy in a furnace and heat it to 430°C for 4 hours, then quench it with water, then put it in liquid nitrogen for 15 minutes for cryogenic treatment, then carry out cold rolling, deform it to 8%, and artificially place it at 200°C aging. After aging for 10 hours, the hardness of the magnesium alloy is as high as 110Hv. It can be seen from Table 1 that the compressive strength and maximum compressibility of the magnesium alloy specimen are 488MPa and 15.4%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com