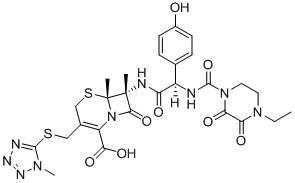

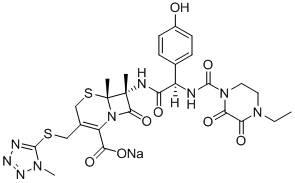

Method for crystallizing cefoperazone sodium

A technology of cefoperazone sodium and cefoperazone acid is applied in the field of crystallization of cefoperazone sodium to achieve the effects of uniform crystal particle size distribution, accelerating crystallization process and preventing coalescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 65ml of acetone to a 250ml three-necked bottle, add 32g of cefoperazone acid under stirring, cool down to 8~10℃, add NaHCO dropwise 3 Adjust the pH of the saturated solution to 6.2~6.8, and maintain this pH until the solid dissolves completely, filter, move the filtrate to a 1000ml three-necked bottle and place it in an ultrasonic generator, control the temperature of 13~18°C, add dropwise to the three-necked bottle while stirring Acetone 100ml, start the ultrasonic generator to seed the crystal for 30~40 minutes after dripping, continue to stir for 30 minutes, continue to drop acetone 700ml into the three-necked bottle, control the temperature at about 15℃, stir and grow the crystal for 70 minutes, filter, and use acetone 100ml of the filter cake was washed and drained, then vacuum-dried at 40°C until the moisture content was acceptable to obtain 30.5g of cefoperazone sodium, with a weight yield of 95.3%, clarity <0.5, sum of impurities: 0.10%, cefoperazone poly...

Embodiment 2

[0025] Add 50ml of acetone and 16ml of ethanol to a 250ml three-necked bottle, add 32g of cefoperazone acid under stirring, cool down to 8~10℃, add NaHCO dropwise 3 Adjust the pH of the saturated solution to 6.2~6.8, and maintain this pH until the solid dissolves completely, filter, move the filtrate to a 1000ml three-necked bottle and place it in an ultrasonic generator, control the temperature of 13~18°C, add dropwise to the three-necked bottle while stirring Acetone 90ml, start the ultrasonic generator to seed the crystal for 30~40 minutes after dripping, continue to stir for 30 minutes, continue to drop acetone 700ml into the three-neck bottle, control the temperature at about 15℃, stir and grow the crystal for 80 minutes, filter, and use acetone 100ml of the filter cake was washed and then sucked dry, vacuum-dried at 40°C until the moisture content was acceptable, and 30.0g of cefoperazone sodium was obtained, with a weight yield of 93.8%, the sum of impurities: 0.12%,...

Embodiment 3

[0027] Add 50ml of acetone and 16ml of isopropanol to a 250ml three-necked bottle, add 32g of cefoperazone acid under stirring, cool down to 8~10℃, add NaHCO dropwise 3 Adjust the pH of the saturated solution to 6.2~6.8, and maintain this pH until the solid dissolves completely, filter, move the filtrate to a 1000ml three-necked bottle and place it in an ultrasonic generator, control 13~18°C, and drop it into the three-necked bottle while stirring Add 90ml of acetone, turn on the ultrasonic generator to seed the crystal for 30~40 minutes after dripping, continue to stir for 30 minutes, continue to drop 700ml of acetone into the three-necked bottle, control the temperature at about 15°C, stir and grow the crystal for 80 minutes, filter, and use Wash the filter cake with 100ml of acetone and drain it, vacuum-dry at 40°C until the water content is acceptable, and obtain 29.6g of cefoperazone sodium, with a weight yield of 92.5%, the sum of impurities: 0.21%, cefoperazone polym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com