Preparation method for rear-earth magnesium alloy

A rare earth magnesium and alloy technology, applied in the field of metal materials, can solve the problems that the tensile strength and yield strength need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

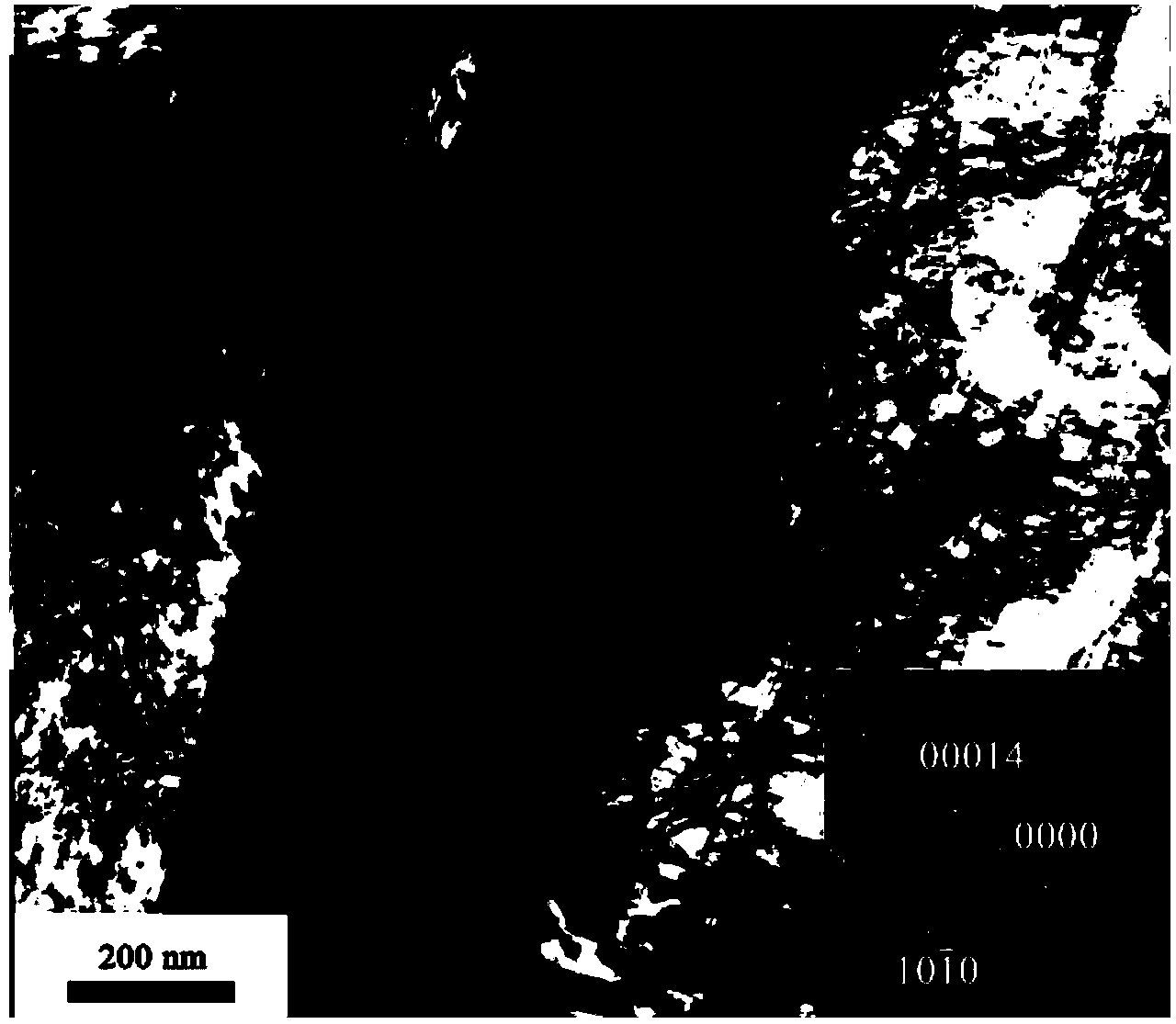

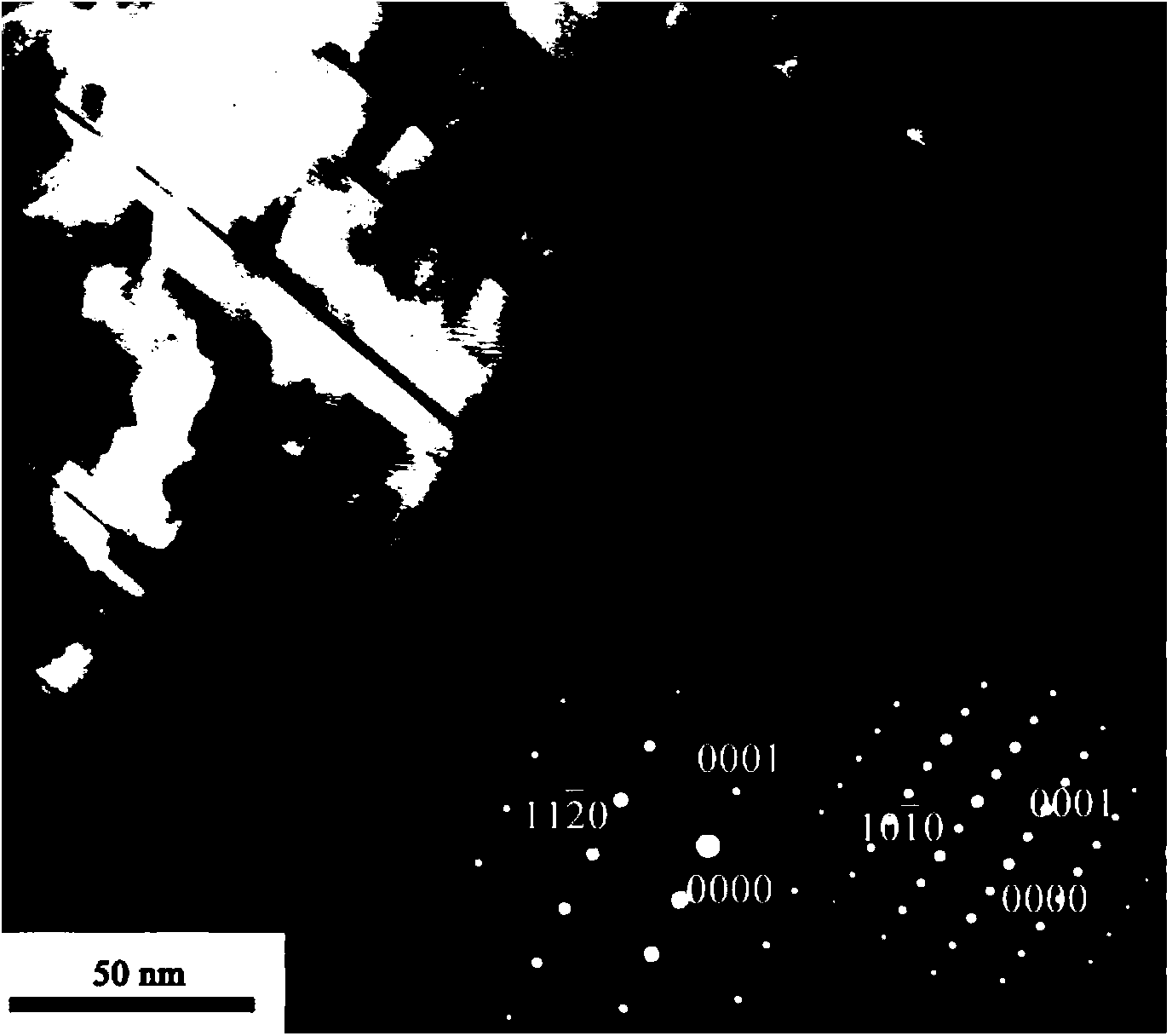

[0028] The invention provides a preparation method of a rare earth magnesium alloy, comprising: casting a magnesium melt, extruding after solution treatment, and then performing cold rolling and aging treatment to obtain a rare earth magnesium alloy; the magnesium melt The elements and contents in the rare earth magnesium alloy are the same as those in the rare earth magnesium alloy; the rare earth magnesium alloy includes Mg, Nd, Gd, Y, Zn and Zr.

[0029] Wherein the rare earth magnesium alloy is a rare earth magnesium alloy containing the above elements well known to those skilled in the art, and there is no special limitation. The present invention preferably includes: 0.1 to 10 wt% of Nd, 10 to 12 wt% of Gd, 3 to 5wt% of Y, 0.5-2wt% of Zn, 0.3-0.8wt% of Zr, the balance of Mg and unavoidable impurities.

[0030] The elements and content in the magnesium melt are the same as those in the rare earth magnesium alloy, and the method for obtaining it can be a method well known ...

Embodiment 1

[0046] 1.1 Divide pure Mg ingots, pure Zn ingots, 20% Mg-Gd master alloys, 20% Mg-Y master alloys, 20% Mg-Nd master alloys and 30% Mg-Zr master alloys, remove scale and oil And dry, according to element content Gd11.2wt%, Y4.5wt%, Zn1.5wt%, Nd1wt%, Zr0.5wt%, the balance is the proportioning material taking of Mg. Preheat and dry No. 5 flux.

[0047] 1.2 Under the protection of 99% carbon dioxide and 1% sulfur hexafluoride mixed gas, add No. 5 flux with 2wt% alloy raw materials, pure Mg ingot and pure Zn ingot weighed in 1.1 into the melting furnace, and heat up to 730 ℃, add the Mg-Gd master alloy and Mg-Nd master alloy weighed in 1.1, stir for 2min, heat up to 780℃, add Mg-Y master alloy and Mg-Zr master alloy, stir for 2min, cool down to 730℃, add No. 5 flux of 2wt% alloy raw materials, after stirring for 12 minutes, blowing in argon gas for refining for 15 minutes, heating up to 780°C, keeping the temperature for 25 minutes, cooling to 750°C for 15 minutes, and removing th...

Embodiment 2

[0056] Turn the round bar obtained in 1.2 into a Ф82mm×120mm extrusion ingot, after 525°C, 24h solution treatment, extrude into a Ф15mm round bar at 425°C, the extrusion ratio is 30:1, and then process it Cold rolling into 120mm×8mm×2.8mm thin sheets, the cold rolling direction is the extrusion direction of the magnesium alloy, the initial rolling amount is 5% / pass, and the subsequent pass rolling amount is 3%~5% / pass , the total rolling amount is 10%, and then aging treatment is carried out under the condition of 210° C. for 24 hours to obtain a rare earth magnesium alloy.

[0057] Performance tests were performed on the rare earth magnesium alloy obtained in Example 2, and its tensile strength was 495 MPa, its yield strength was 466 MPa, and its elongation was 3.1%.

[0058] The rare earth magnesium alloy obtained in embodiment 2 is carried out tensile property test, obtains its tensile curve figure, as Figure 4 Shown in b.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com