Serpentine channel solar cell waste-heat recovery unit

A solar cell and waste heat recovery technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of sudden drop in photoelectric conversion efficiency of batteries, shortening the service life of battery panels, and thermal pollution of the surrounding environment, so as to improve photoelectric conversion efficiency, Effect of lowering battery temperature and preventing heat pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

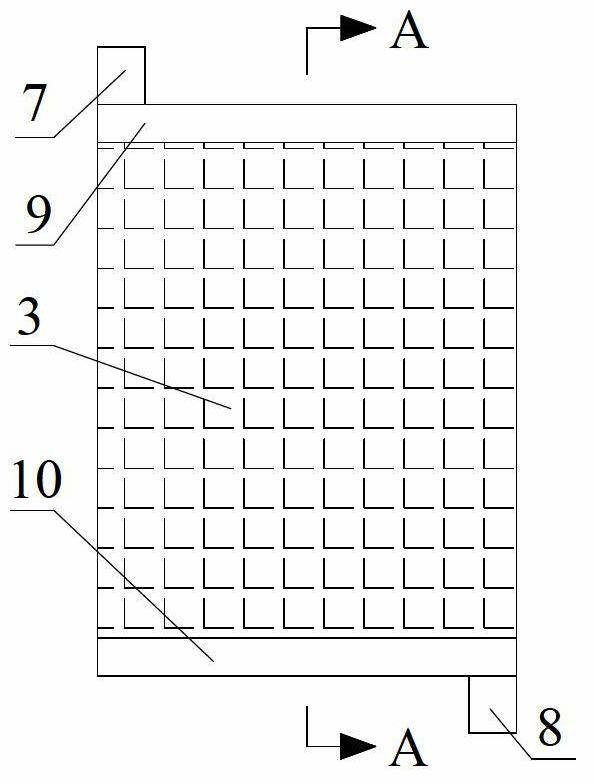

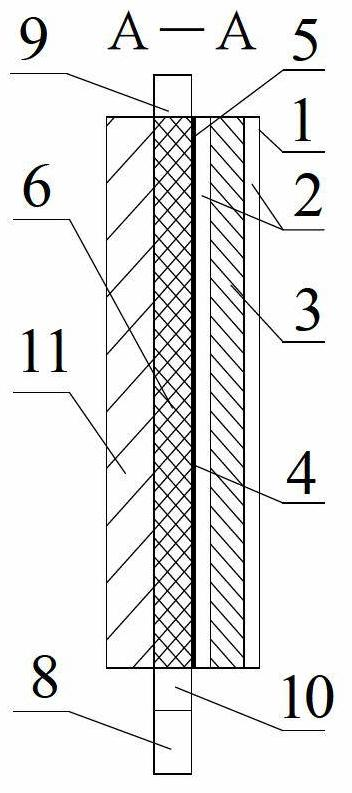

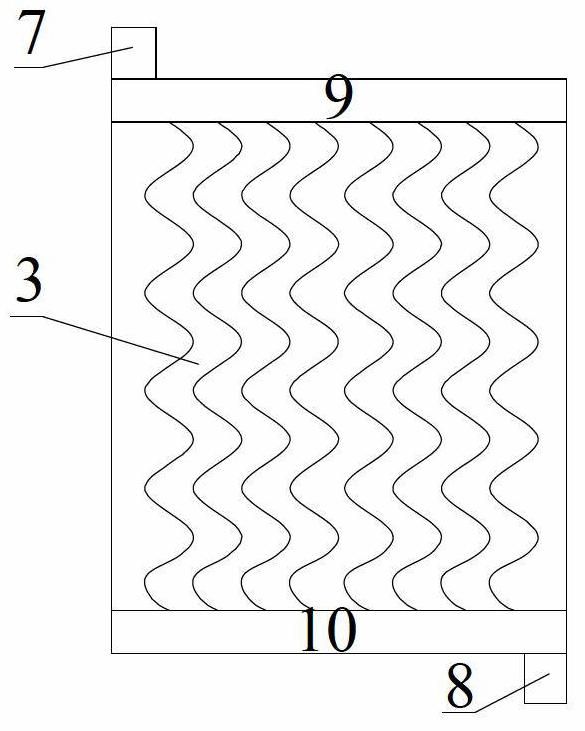

[0015] Such as figure 1 , figure 2 and image 3 As shown, the inventive device is mainly composed of a photovoltaic template battery system and a waste heat recovery device, wherein the photovoltaic template battery system is composed of a front glass cover 1, air 2, solar cells 3 and a rear glass cover 4, and the waste heat recovery device includes a serpentine The water flow channel 6, the water inlet 7, the water outlet 8, the water inlet connecting box 9 and the water outlet connecting box 10, wherein the water inlet connecting box 9 and the water outlet connecting box 10 are respectively connected to it on both sides of the serpentine water flow channel 6, and the water inlet 7 and The water inlet connection box 9 is connected, and the water outlet connection box 10 is connected with the water outlet 8; the transparent silica gel 5 bonds the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com