Method of manufacturing active carbon for waste water treatment using waste tyre

A wastewater treatment and activated carbon technology, applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, and other chemical processes, can solve the problems of limited wastewater treatment applications, expensive manufacturing costs, etc., and achieve improved comprehensive utilization efficiency, low cost, and The effect of enhancing the effect of biological treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

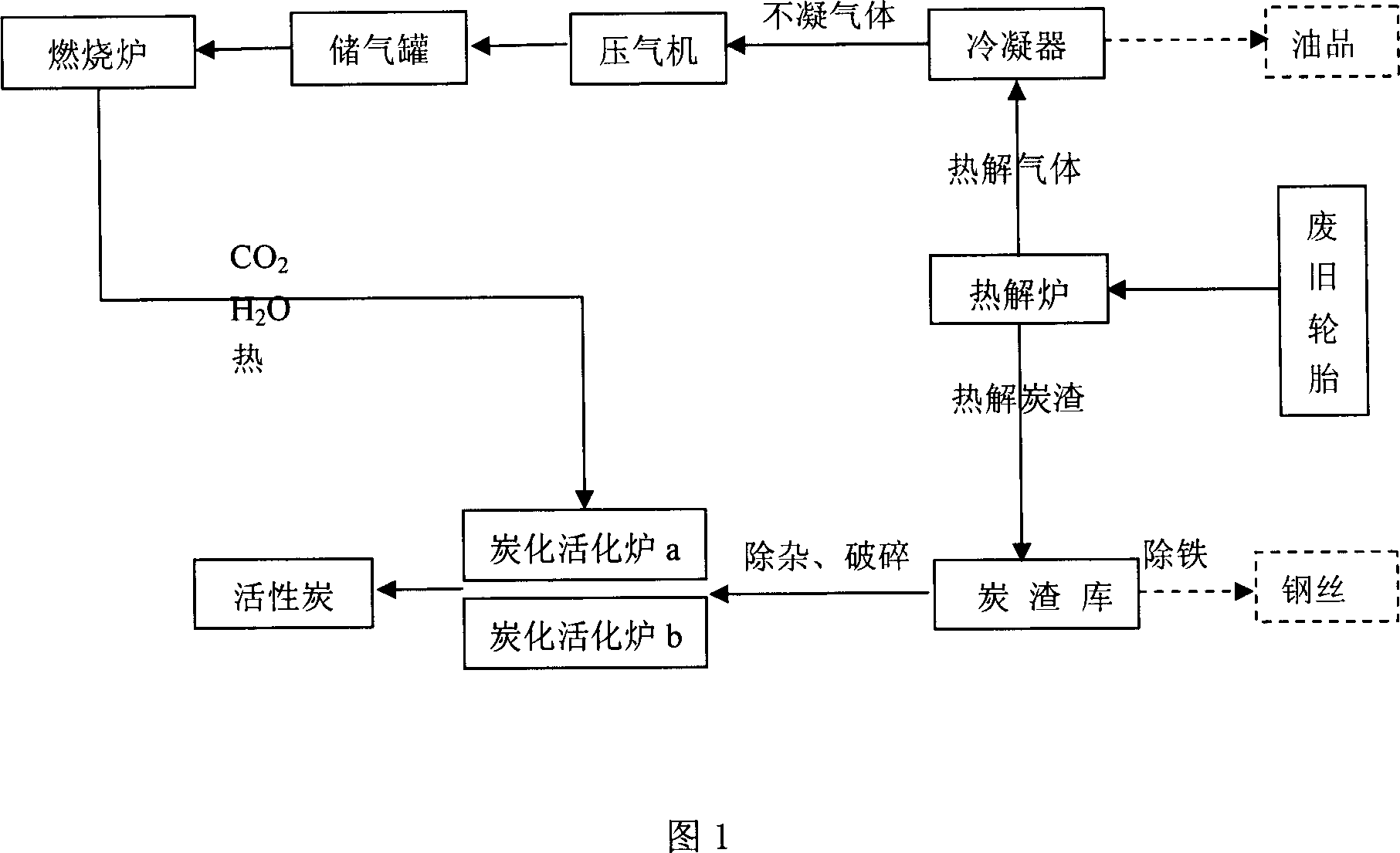

[0030] 1 Waste tires (whole) are mechanically sent to the pyrolysis furnace.

[0031] 2 The temperature in the pyrolysis furnace is 380 °C, and the pyrolysis reaction is carried out,

[0032] 2.1 The carbon slag produced by pyrolysis is sent to the carbonization activation furnace a after iron removal, impurity removal, and crushing;

[0033] 2.2 After the gas produced by pyrolysis passes through the condenser to obtain oil, the non-condensable gas is sent to the gas storage tank through the compressor by conventional methods, and then passed into the combustion furnace, and is burned through the hydrocarbon fuel combustion nozzle to generate high-heat CO 2 and H 2 O;

[0034] 3 The non-condensable gas produced by pyrolysis is burned to produce high-heat CO 2 and H 2 The O gas flow is introduced into the carbonization activation furnace a, so that the reaction temperature of the carbonization activation furnace is maintained at 700 ° C, and the reaction time is 20 hours; ...

example 2

[0038] 1 Waste tires (crushed) are mechanically sent to the pyrolysis furnace.

[0039] 2 The temperature in the pyrolysis furnace is 380 °C, and the pyrolysis reaction is carried out,

[0040] 2.1 The carbon slag produced by pyrolysis is sent to the carbonization activation furnace a after iron removal, impurity removal, and crushing;

[0041] 2.2 After the gas produced by pyrolysis passes through the condenser to obtain oil, the non-condensable gas is sent to the gas storage tank through the compressor by conventional methods, and then passed into the combustion furnace, and is burned through the hydrocarbon fuel combustion nozzle to generate high-heat CO 2 and H 2 O;

[0042] 3 The non-condensable gas produced by pyrolysis is burned to produce high-heat CO 2 and H 2 The O gas flow is introduced into the carbonization activation furnace a, so that the reaction temperature of the carbonization activation furnace is maintained at 950 ° C, and the reaction time is 1 hour; ...

example 3

[0046] 1 Waste tires (whole) are mechanically sent to the pyrolysis furnace.

[0047] 2 The temperature in the pyrolysis furnace is 500 ℃, and the pyrolysis reaction is carried out,

[0048]2.1 The carbon slag produced by pyrolysis is sent to the carbonization activation furnace a after iron removal, impurity removal, and crushing;

[0049] 2.2 After the gas produced by pyrolysis passes through the condenser to obtain oil, the non-condensable gas is sent to the gas storage tank through the compressor by conventional methods, and then passed into the combustion furnace, and burned through the hydrocarbon fuel combustion nozzle to generate high-heat CO 2 and H 2 O;

[0050] 3 The non-condensable gas produced by pyrolysis is burned to produce high-heat CO 2 and H 2 The O gas flow is introduced into the carbonization activation furnace a, so that the reaction temperature of the carbonization activation furnace is maintained at 700 ° C, and the reaction time is 10 hours;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com