Management system for fine spinning winder and fine spinning winder

A management system and winding machine technology, which is applied in thin material processing, textile and papermaking, and conveying filamentous materials, etc., can solve the problems of reduced production efficiency, increase, and cumbersomeness, and achieve the goal of suppressing quality decline and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

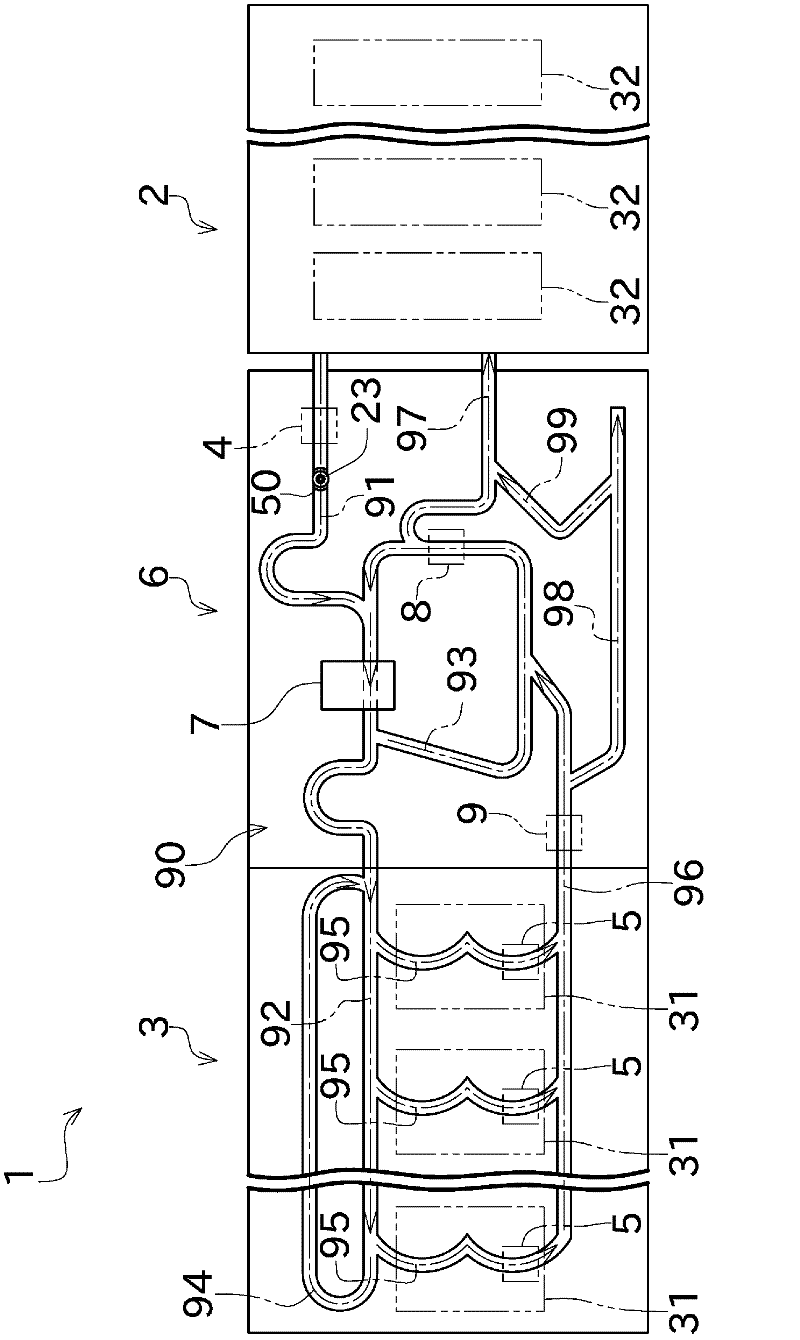

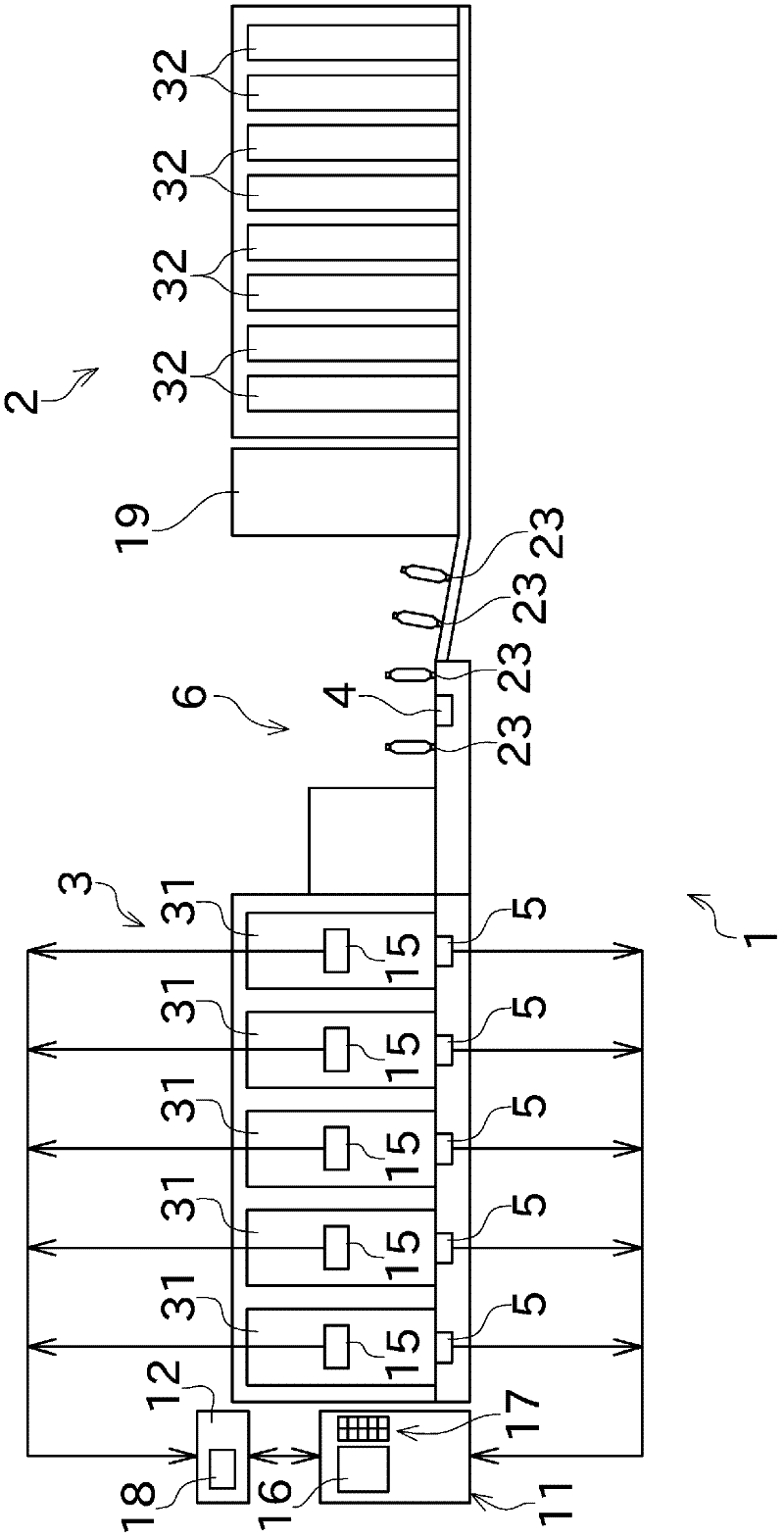

[0028] Next, embodiments of the invention will be described. figure 1 It is a schematic plan view showing the worsted spinning winder 1 according to one embodiment of the present invention viewed from above. figure 2 It is a schematic front view and block diagram of the worsted spinning winder 1 .

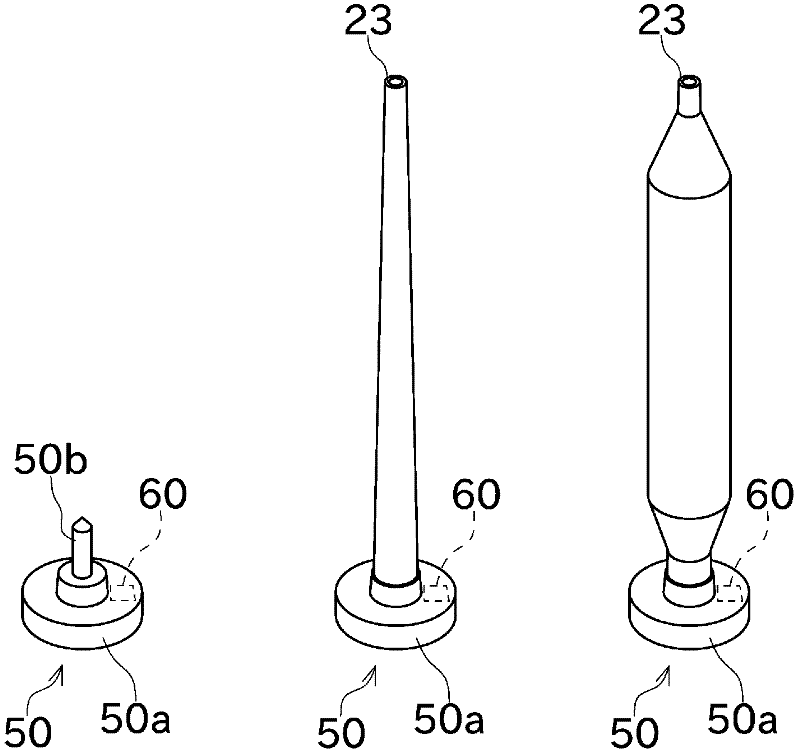

[0029] Such as figure 1 As shown, the worsted spinning winder 1 is provided with a side pan conveying path 90 for transporting a side pan (conveying body) 50 on which the bobbin 23 is placed, and the spinning machine 2 and the winder 3 are disposed on the side pan conveying path 90. And bobbin automatic feeding device (bobbin conveying mechanism) 6. The side pan conveying path 90 connects the spinning machine 2 and the winder 3 in an annular shape, and the bobbin 23 (the side pan 50 ) circulates in the side pan conveying path 90 . Among them, although figure 1 Only one of the bobbin 23 and the side tray 50 is shown in the center, but actually a plurality of side trays 50 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com