Algae-controlling laterite compound flocculant as well as preparation method and applications thereof

A composite flocculant and laterite technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of small water area, high cost, slow effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) The soil sample collection site was located in Huguangyan area, Zhanjiang City, Guangdong Province. Taking layered mining to take lateritic soil samples, according to the literature (Xu Jinhong, Xu Ruisong, Xia Bin, Miao Li, Zhu Zhaoyu. "The content and distribution characteristics of rare earth elements in red soil in Guangdong", China Soil and Fertilizer, 2007(1): 18- 21), it can be known that this laterite contains the laterite of the following components by percentage: SiO 2 36.27~72.91%, Al 2 O 3 9.19~28.37%, Fe 2 O 3 4.4~15.66%, FeO 0.04~0.09%, MnO 0.03~0.22%, CaO 0.06~1.0%, MgO 0.07~0.36%, K 2 O 0.47~0.62%, Na 2 O 0.09~1.4%, P 2 O 5 0.04-0.17%; laterite soil samples are dried by natural air drying or oven drying, pulverized, and passed through a 20-mesh sieve to obtain laterite powder;

[0032] (2) 100g of laterite powder, 12g of polyaluminum chloride and 10g of ferric chloride were added to the ball mill, and under normal temperature and pressure...

Embodiment 2

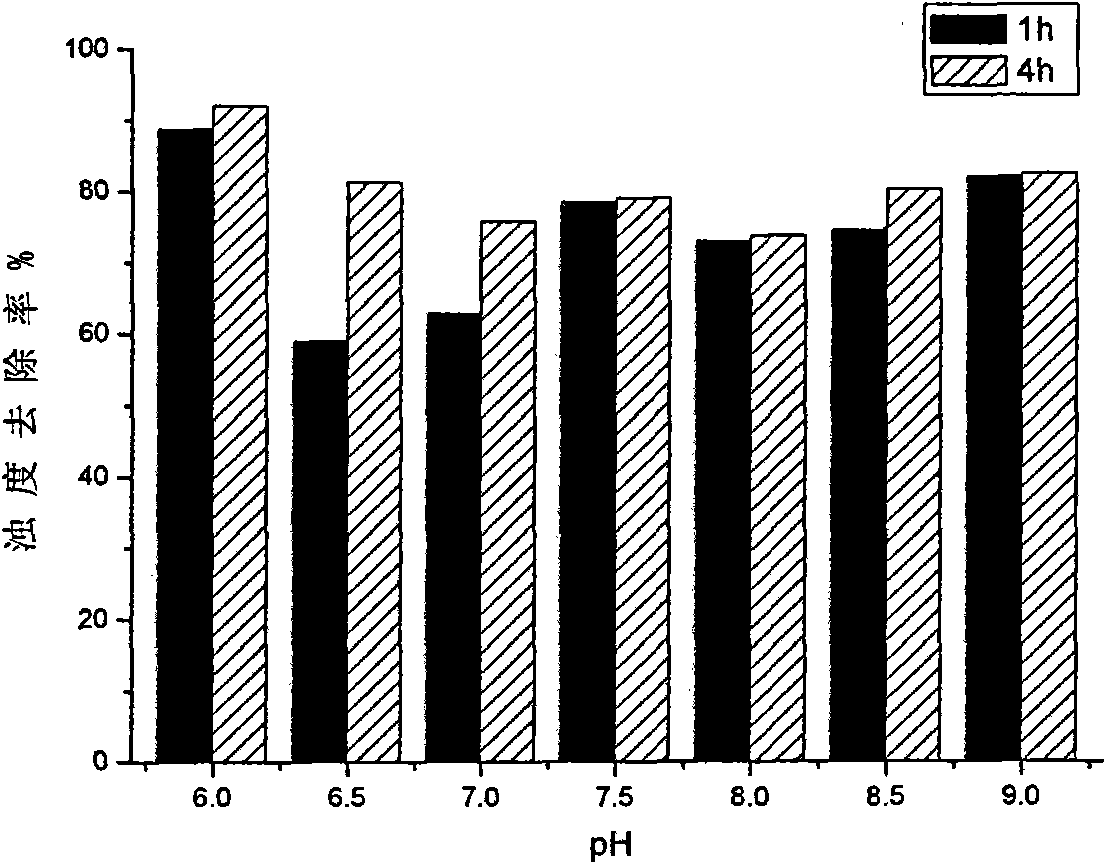

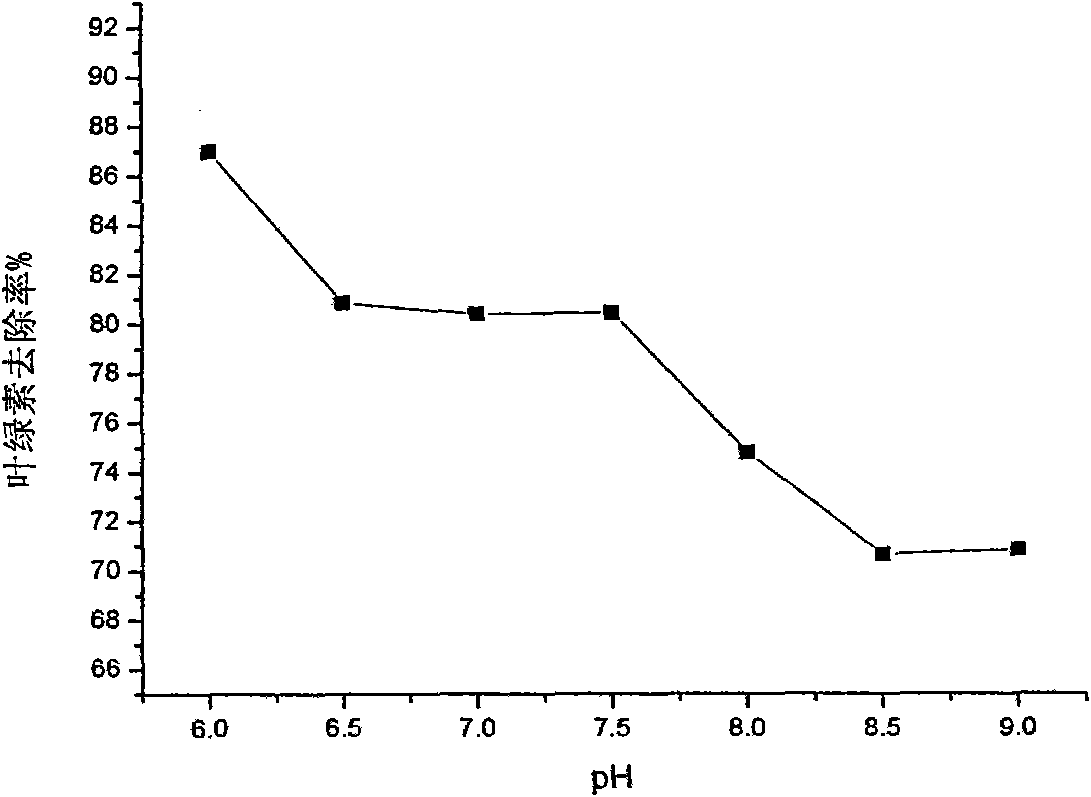

[0044] The source of the water sample was the same as that of Example 1, and the turbidity in the water sample was measured to be 15.07 NTU, and the content of chlorophyll a was 153.34 μg / L. Take a certain amount of laterite powder obtained in step (1) of Example 1 and add it to a 1L water sample, then add 60 mg of polyaluminum chloride and 50 mg of ferric chloride respectively, and after stirring and settling, measure turbidity and chlorophyll a. removal rate.

[0045] a) Add 200 mg of laterite powder, 60 mg of polyaluminum chloride and 50 mg of ferric chloride to a 1 L water sample, stir on a magnetic stirrer for 3 minutes, and then let it settle. After 1 hour, the supernatant of the water sample was extracted to measure the turbidity. Compared with the turbidity of the original water sample, the removal rate of turbidity in 1 hour was 80.55%, and that in 4 hours was 88.59%. After 4 hours, 100 mL of the supernatant of the water sample was extracted, After the chlorophyll wa...

Embodiment 3

[0053] The source of the water sample is the same as that of Example 1. The measured turbidity in the water sample was 16.51 NTU, and the chlorophyll a content was 161.62 μg / L. The laterite composite flocculant prepared in Example 1 was added to a 1L water sample, and after stirring and settling, the turbidity and the removal rate of chlorophyll a were measured.

[0054] a) Add 120 mg of laterite composite flocculant (containing 98.36 mg of soil sample, 11.80 mg of polyaluminum chloride, and 9.84 mg of ferric chloride) to 1 L of water sample, stir on a magnetic stirrer for 3 minutes, and let it settle. After 1 hour, the supernatant of the water sample was extracted to measure the turbidity. Compared with the turbidity of the original water sample, the turbidity removal rate of 1 hour was 74.09%, and the turbidity removal rate of 4 hours was 84.55%; After the chlorophyll was extracted with a chlorophyll suction filter pump, it was extracted with a 9:1 acetone solution for 24 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com