Multi-stage treatment process for electroplating wastewater of centralized park zone

A technology for electroplating wastewater and treatment process, which is applied in the fields of metallurgical wastewater treatment, neutralization water/sewage treatment, water/sewage treatment, etc. It can solve the problems of failing to meet the national discharge standard and being practical, and achieve the effect of ensuring the compliance rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

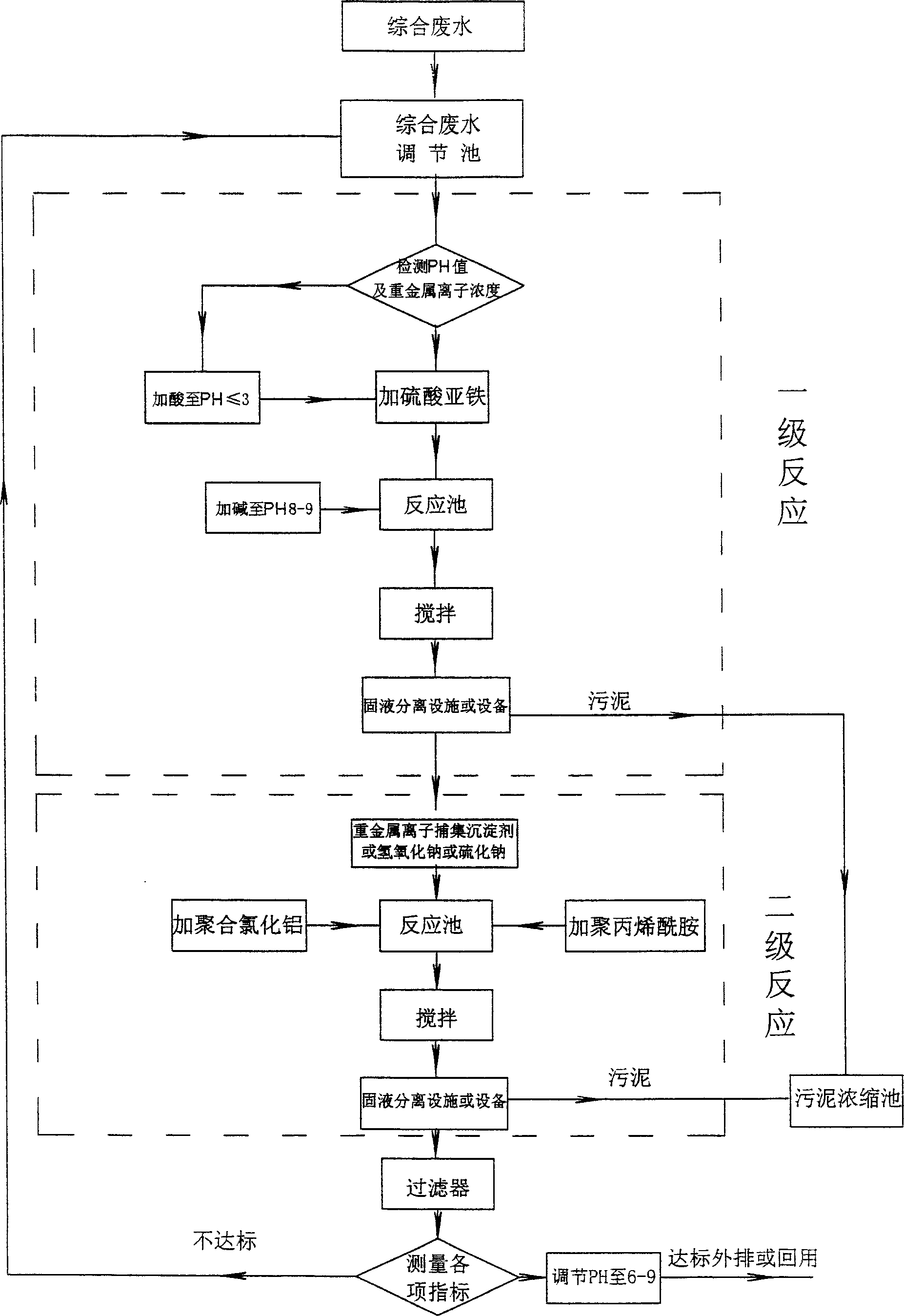

[0024] On April 27, 2005, the electroplating wastewater (except cyanide-containing and oil-containing wastewater) discharged from each factory entered the comprehensive wastewater regulating tank for treatment. The process steps are as follows:

[0025] 1. First-order reaction: The PH value of the comprehensive wastewater is 5.3, and the concentration of heavy metal ions is: Cr 6+ -35mg / L, Cu 2+ -24.3mg / L, Ni 2+ -16.8mg / L. Use the automatic dosing system to automatically add hydrochloric acid to the wastewater (the ratio of hydrochloric acid addition is based on the pH value in the wastewater), and adjust the pH value of the water to 2.97; add sulfuric acid to the pipeline mixer at 13 times the concentration of chromium ions (455mg / L) Ferrous, then the wastewater enters the reaction tank, and the automatic dosing system is used to add sodium hydroxide to the wastewater to adjust the pH of the wastewater to 8.9. After the wastewater is fully mixed and reacted by hydraulic ag...

Embodiment 2

[0031] On May 16, 2005, the electroplating wastewater discharged from each factory entered the comprehensive wastewater regulating pool for treatment. The process steps are as follows:

[0032] 1. First-order reaction: The automatic dosing system is used to automatically add sodium hydroxide to the wastewater (the ratio of sodium hydroxide addition is based on the pH value in the wastewater). After testing, the pH value of the comprehensive wastewater is: 2.8, and the concentration of heavy metal ions is: Cr 6+ -44mg / L, Cu 2+ -42.6mg / L, Ni 2+ -53.5mg / L. Add ferrous sulfate to the pipeline mixer at 14.5 times (638 mg / L) the concentration of chromium ions, then the wastewater enters the reaction tank, and the pH value in the wastewater is adjusted to 8.4 by adding sodium hydroxide to the wastewater by using the automatic dosing system. After the wastewater is fully mixed and reacted by hydraulic agitation in the reaction tank for 23 minutes, it enters the inclined tube sedimen...

Embodiment 3

[0038] On June 23, 2005, the electroplating wastewater discharged from each factory entered the comprehensive wastewater regulating pool for treatment. The process steps are as follows:

[0039] 1. Primary reaction: The automatic dosing system is used to automatically add sodium hydroxide to the wastewater (the ratio of sodium hydroxide is based on the pH value in the wastewater). After testing, the pH value in the comprehensive wastewater is: 1.8, and the concentration of heavy metal ions is: Cr 6+ -72.8mg / L, Cu 2+ -72.6mg / L, Ni 2+ -123.5mg / L. Add ferrous sulfate to the pipeline mixer at 16 times (1164.8mg / L) the concentration of chromium ions, then the wastewater enters the reaction tank, and the pH value of the wastewater is adjusted to 8.3 by adding sodium hydroxide to the wastewater by using the automatic dosing system . The wastewater is fully mixed and reacted by hydraulic stirring in the reaction tank for 25 minutes, then enters the inclined tube sedimentation tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com