Technical process for producing chloride aluminum

A technology of polyaluminum chloride and process method, which is applied in the direction of aluminum chloride, aluminum halide, flocculation/precipitation water/sewage treatment, etc., and can solve the problems of calcium chloride suspended solids, water-insoluble substances exceeding the standard, and high production costs. Achieve the effects of shortening natural settlement time, increasing production and saving initial investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

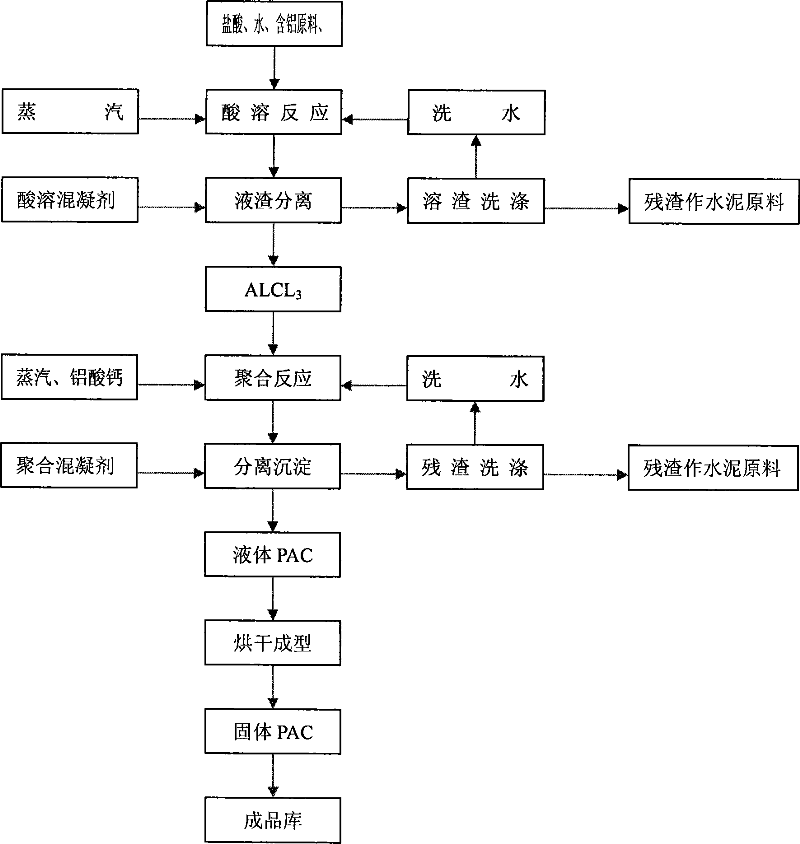

Method used

Image

Examples

Embodiment 1

[0034] The first step of acid dissolution reaction:

[0035] In the acid-resistant reactor equipped with stirring and acid mist recovery device, add water and hydrochloric acid in sequence to make 16-25% acid-soluble reaction solution. Start stirring and preheating to 40°C-60°C, cut off the heat source, and adjust the amount of bauxite in the formula step by step (bauxite can be boehmite ore, trihydrate bauxite, low-grade bauxite, etc.) (Based on the acid-soluble aluminum content of 30%), put all the liquid in before the liquid temperature is 90°C, and rely on self-heating reaction when the temperature rises to ≥100°C, heat again, and strengthen the reaction at normal pressure for 2-4 hours, and the reaction temperature is 105°C-115°C between. Before discharging, add acid-soluble coagulant polyacrylamide in an amount of 0.005% to 0.05% of the volume of the aluminum-containing acid solution, and stir for 1-2 minutes. Put the reaction material into the liquid slag separation t...

Embodiment 2

[0039] The first step of acid dissolution reaction:

[0040] In the acid-resistant reactor equipped with stirring and acid mist recovery device, add water and hydrochloric acid in sequence to make 16-25% acid-soluble reaction solution. Start stirring and preheating to 40°C-60°C, cut off the heat source, add the amount of kaolin in the formula (calculated as 30% acid-soluble aluminum content) in batches before the liquid temperature is 90°C, and rely on self-heating reaction to raise the temperature ≥ 100 ℃, heat again, and strengthen the reaction at normal pressure for 2-4 hours, and the reaction temperature is between 105 ℃ and 115 ℃. Before discharging, add acid-soluble coagulant polyacrylamide in an amount of 0.005% to 0.05% of the volume of the aluminum-containing acid solution, and stir for 1-2 minutes. Put the reaction material into the liquid slag separation tank, let it stand for precipitation, and the supernatant is the mother liquor of the next step polymerization r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com