Method for concentrating and dehydrating sludge

A technology of sludge concentration and treatment method, applied in dewatering/drying/concentrating sludge treatment, separation methods, chemical instruments and methods, etc., can solve the problems of poor environment, high energy consumption, and high effluent SS

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

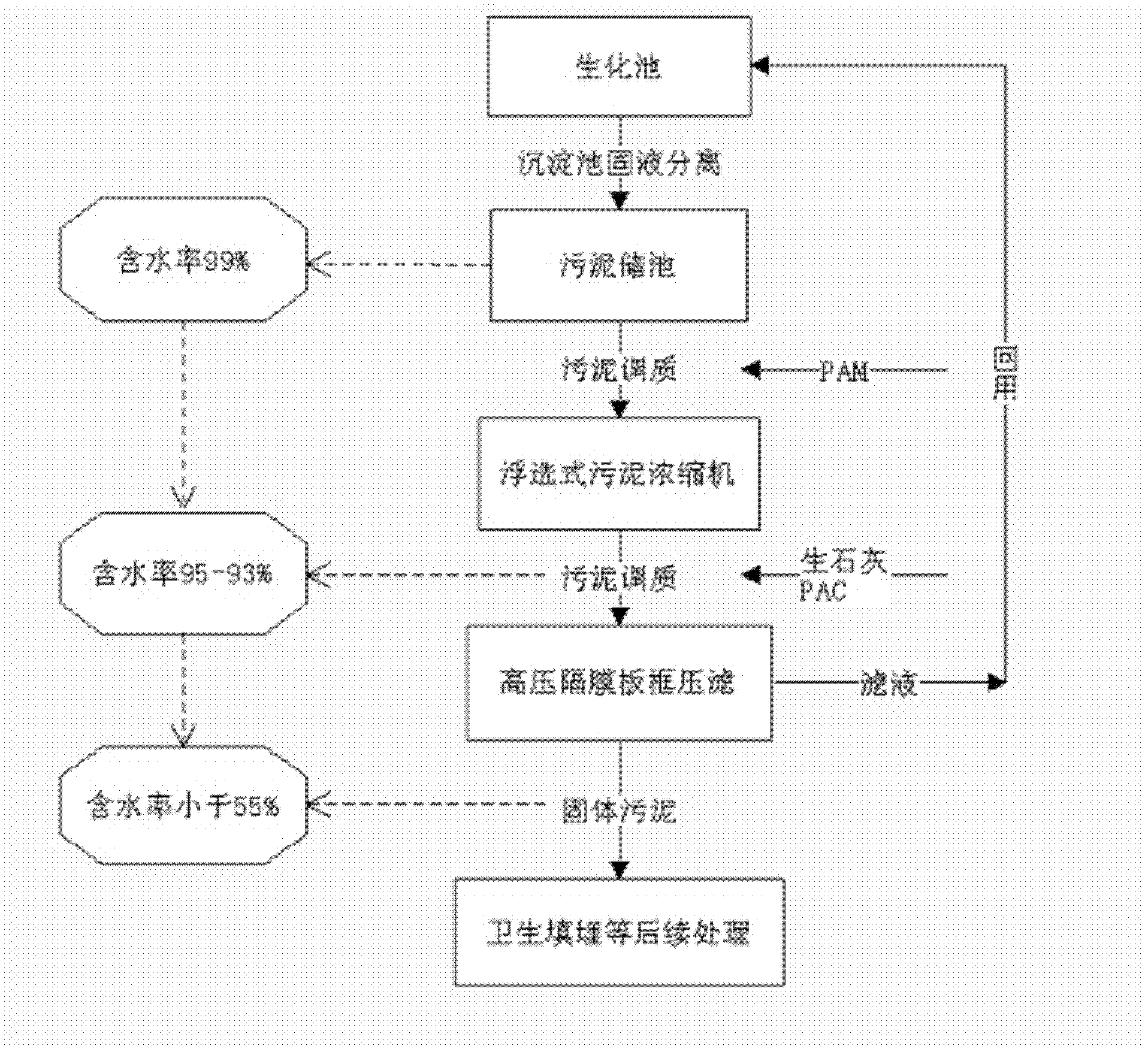

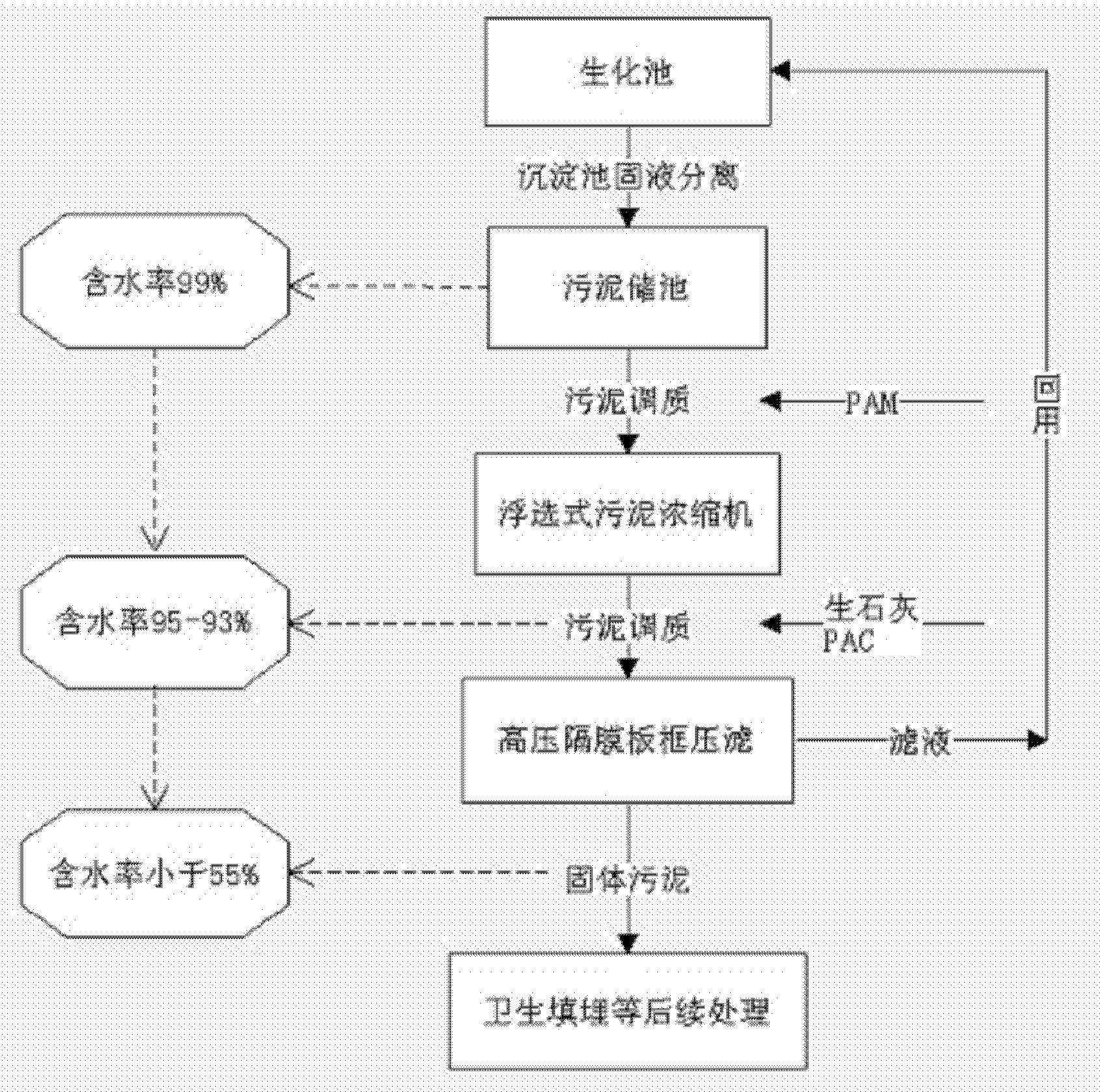

[0024] see figure 1 , figure 2 , the treatment of municipal sludge:

[0025] The first step: sludge conditioning

[0026] Discharge the remaining sludge produced by the domestic sewage after the solid-liquid separation treatment in the biochemical tank and the sedimentation tank into the sludge storage tank, and the sludge in the sludge storage tank (with a moisture content of 99%) is pumped into the sludge conditioning tank, adding polyacrylamide (PAM) to condition the sludge, the addition of polyacrylamide (PAM) is 0.3% of the absolute dry sludge mass;

[0027] Step 2: Sludge Concentration

[0028] The conditioned sludge is pumped into the air-water mixing contact chamber of the flotation sludge thickener, and the sludge passing through the air-water mixing contact chamber rises to the top and is scraped into the sludge tank by the scraper, and clean water Enter the clean water test through the collection system in the clean water collection area. The moisture content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com