Biochemical treatment device of kitchen wastes

A biochemical treatment device, a technology for kitchen waste, applied in grain processing, chemical/physical processes, mixers with rotary stirring devices, etc. problem, to achieve the effect of removing odor, improving efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

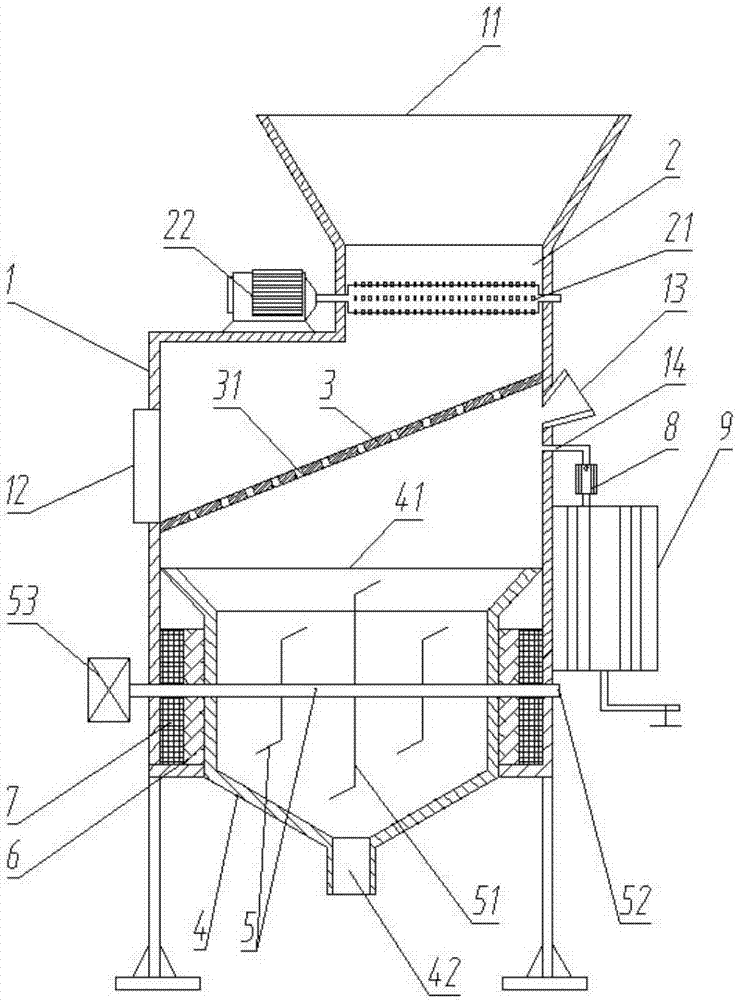

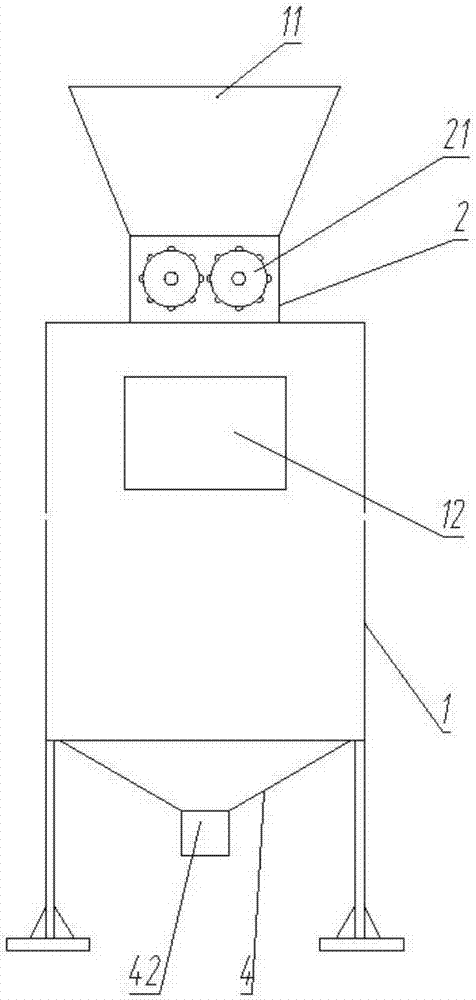

[0015] The present invention is described below in conjunction with accompanying drawing.

[0016] as attached figure 1 , 2 Shown is a kind of food waste biochemical treatment device according to the present invention, comprising a box body 1; a feed port 11 is installed above the box body 1, and a discharge port 12 is processed on the side wall; the feed port 11 and the box body A crushing chamber 2 is installed between the main body 1; a crushing mechanism is fixed in the crushing chamber 2; the crushing mechanism includes a hob 21 and a driving motor 22, and the hobs 21 are two groups, which mesh with each other and are arranged forward and backward along the horizontal direction. They are respectively fixed on the side wall of the crushing chamber 2 through bearings; the drive motor 21 is installed on the side of the crushing chamber 2 to drive the hob 21 to rotate; the box body 1 is provided with a partition 3 and a material receiving cylinder 4; the partition 3 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com