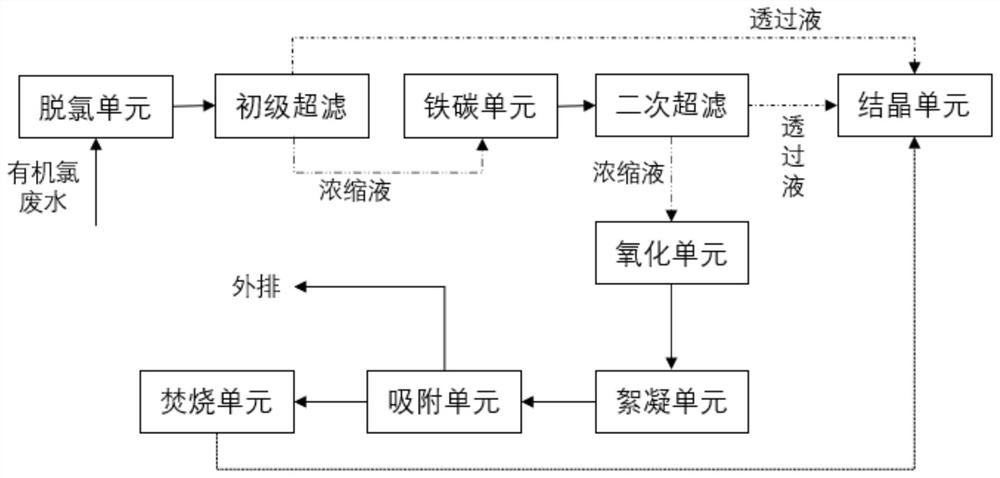

Landfill leachate treatment system

A technology of landfill leachate and treatment system, applied in the field of landfill leachate treatment system, can solve the problems of increasing system energy consumption, large energy consumption, oxygen consumption, etc., and achieve the effect of improving biochemical treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

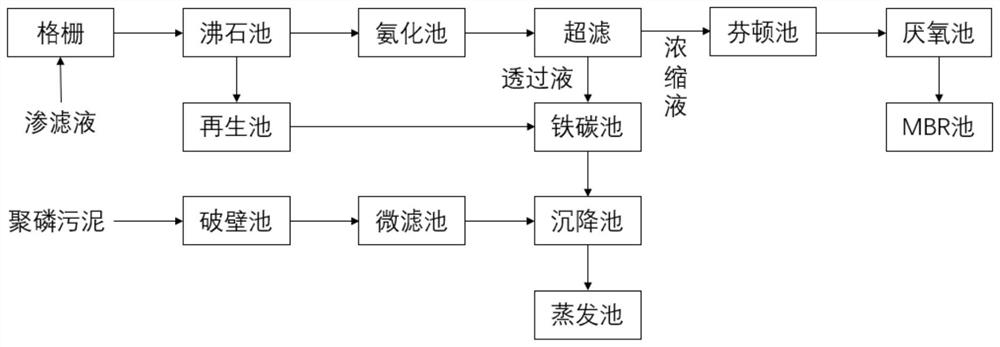

Embodiment 1

[0035] Landfill leachate adopts landfill leachate piled up in a waste incineration power plant, CODcr19800mg / L; NH3-N1122mg / L; organic nitrogen 1329mg / L.

[0036] The pretreated landfill leachate is transported to the zeolite pool for ammonia nitrogen adsorption treatment. The concentration of ammonia nitrogen in the effluent is 238mg / L, and the organic nitrogen is 974mg / L. Then it enters the ammoniation pool for ammoniation of organic nitrogen substances in the wastewater. The ammonified wastewater is subjected to ultrafiltration treatment, and the ammonia nitrogen effluent produced by ultrafiltration and regeneration treatment is transported to the iron-carbon tank for treatment, and the iron-carbon effluent is transported to the sedimentation tank, and the magnesium source and phosphorus-accumulated sludge are added to the sedimentation tank The product forms struvite, and the nitrogen and phosphorus elements can be recovered. The nitrogen recovery rate is about 56%, and the...

Embodiment 2

[0038] Landfill leachate adopts landfill leachate piled up in a waste incineration power plant, CODcr23495mg / L; NH3-N963mg / L; organic nitrogen 1129mg / L.

[0039] The pretreated landfill leachate is transported to the zeolite pool for ammonia nitrogen adsorption treatment. The concentration of ammonia nitrogen in the effluent is 179mg / L, and the organic nitrogen is 910mg / L. Then it enters the ammoniation pool for ammoniation of organic nitrogen substances in the wastewater. The ammonified wastewater is subjected to ultrafiltration treatment, and the ammonia nitrogen effluent produced by ultrafiltration and regeneration treatment is transported to the iron-carbon tank for treatment, and the iron-carbon effluent is transported to the sedimentation tank, and the magnesium source and phosphorus-accumulated sludge are added to the sedimentation tank The product forms struvite, and the nitrogen and phosphorus elements can be recovered. The nitrogen recovery rate is about 61%, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com