Equipment for treating organic wastewater through joint of electrolyzation and oxidant

A technology for organic wastewater and combined treatment, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc. It can solve the problems of low space-time efficiency, achieve high space-time efficiency and improve biochemical treatment efficiency. , the effect of saving electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

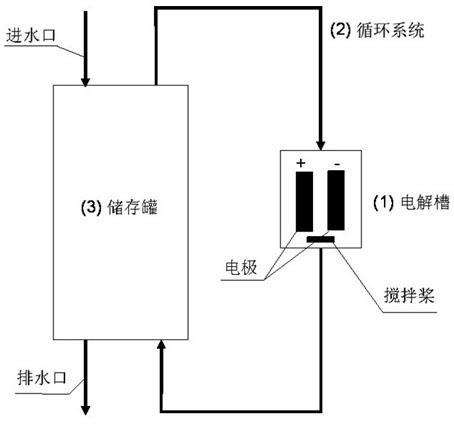

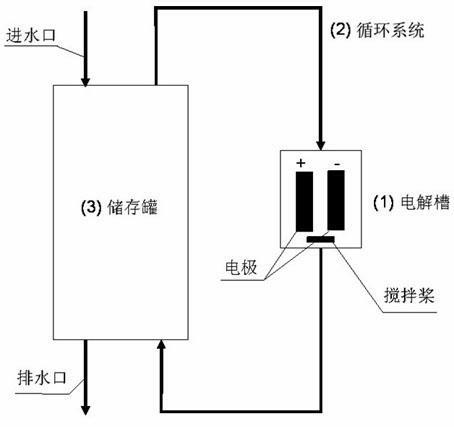

[0020] Equipment construction and operation. Such as figure 1 The electrolysis-oxidant joint treatment equipment for organic wastewater shown is composed of an electrolytic cell, a circulation system and a storage tank. The storage tank is provided with a water inlet and a drainage port. One end of the electrolytic cell is connected to the storage tank through the circulation system, and the other end is directly connected to the storage tank. The tanks are connected, the circulation system includes a circulation pump and pipelines, 0.1mol / L hypochlorous acid is added as an oxidant in the electrolytic cell and a BDD electrode is installed, and the electrode is connected to a direct current with a voltage of 12.0V and a current of 4.0A. During operation, the wastewater first enters the storage tank, and then flows into the electrolytic cell from one end of the electrolytic cell through the circulating pump, and then connects the current, and electrolysis and oxidation decomposi...

Embodiment 2

[0022] Utilize the equipment of Example 1 and adopt BDD electrode and hypochlorous acid to oxidize and degrade landfill leachate. The COD of the leachate reaches 3480mg / L, and the concentration of ammonia nitrogen reaches 4000mg / L. Under the conditions of voltage 12.0V and current 4.0A, hypochlorous acid with a concentration of 0.1mol / L is added, electrolyzed for 5 hours, COD drops to 85mg / L, ammonia nitrogen Reducing to 50 mg / L, the degradation effect is remarkable, and it has a good decolorization effect. COD and ammonia nitrogen did not decrease significantly when only hypochlorous acid was added. However, when electrolysis and hypochlorous acid were combined, the degradation rate of COD and ammonia nitrogen was about 1.5 times faster.

Embodiment 3

[0024] Utilize the equipment of embodiment 1 and adopt BDD electrode and hypochlorous acid to electrolyze phenol wastewater. Phenol wastewater COD=2240mg / L, continuous electrolysis under the conditions of applied voltage 12.0V, current 4.0A, adding hypochlorous acid with a concentration of 0.1mol / L, after 5 hours electrolysis COD decreased to 35mg / L. Simply adding hypochlorous acid has no degradation, but when electrolysis and hypochlorous acid are combined, the rate is significantly improved, which is nearly 2 times faster than that of pure electrolysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com