Double-MBR-method sewage treatment process combined with ozone oxidation

A technology for ozone oxidation and sewage treatment, applied in the direction of oxidation water/sewage treatment, biological water/sewage treatment, flotation water/sewage treatment, etc., can solve the problems of large ozone dosage and high operating costs, and achieve investment and operation Low cost, low operating cost, and the effect of reducing membrane pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

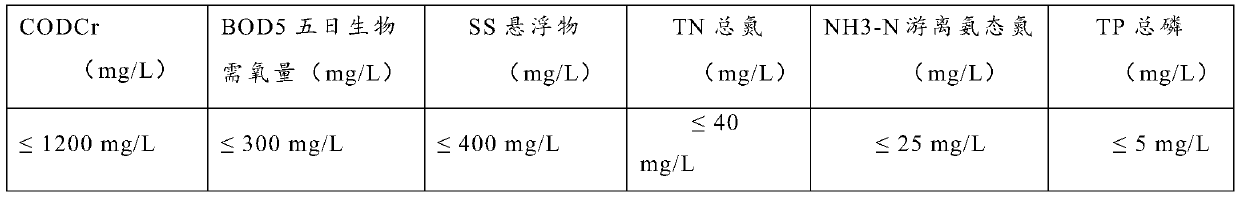

[0048] Example 1: A textile printing and dyeing wastewater treatment plant has a daily treatment capacity of 5000m3 / d, and the design water quality of the plant is shown in Table 1.

[0049] Table 1 Design Influent Water Quality Table

[0050]

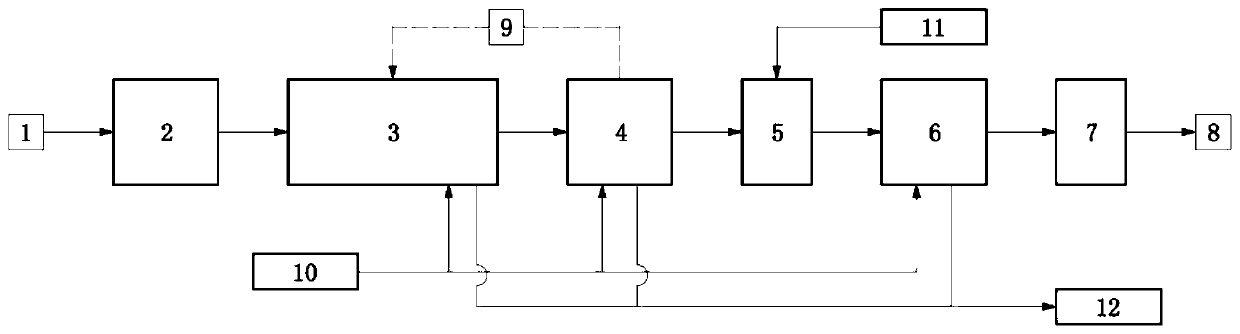

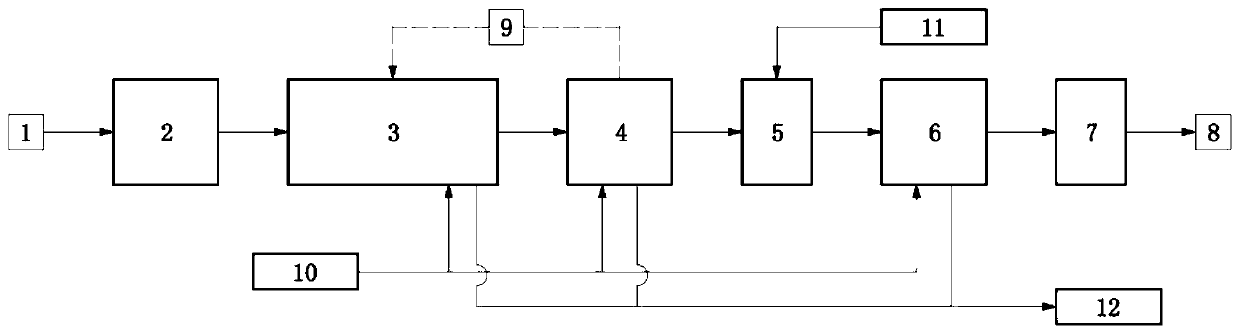

[0051] refer to figure 1 , the present invention firstly provides a sewage treatment device, comprising a water inlet system 1, a pretreatment system 2, a biochemical pool 3, a primary MBR membrane pool 4, an ozone oxidation pool 5, a secondary MBR membrane pool 6, a clean water pool 7, Water outlet system 8 , mixed liquid return system 9 , aeration system 10 , ozone generator 11 , and sludge treatment system 12 . Among them, the biochemical pool 3, the first-level MBR membrane pool 4 and the second-level MBR membrane pool are respectively connected to the aeration system 10 and the sludge treatment system 12, and the mixed liquid reflux is set between the biochemical pool 3 and the first-level MBR membrane pool 4 system9.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com