Treatment method of coal gasification wastewater

A technology of coal gasification wastewater and treatment method, which is applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. complex issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment is used to illustrate the treatment method of coal gasification wastewater provided by the present invention.

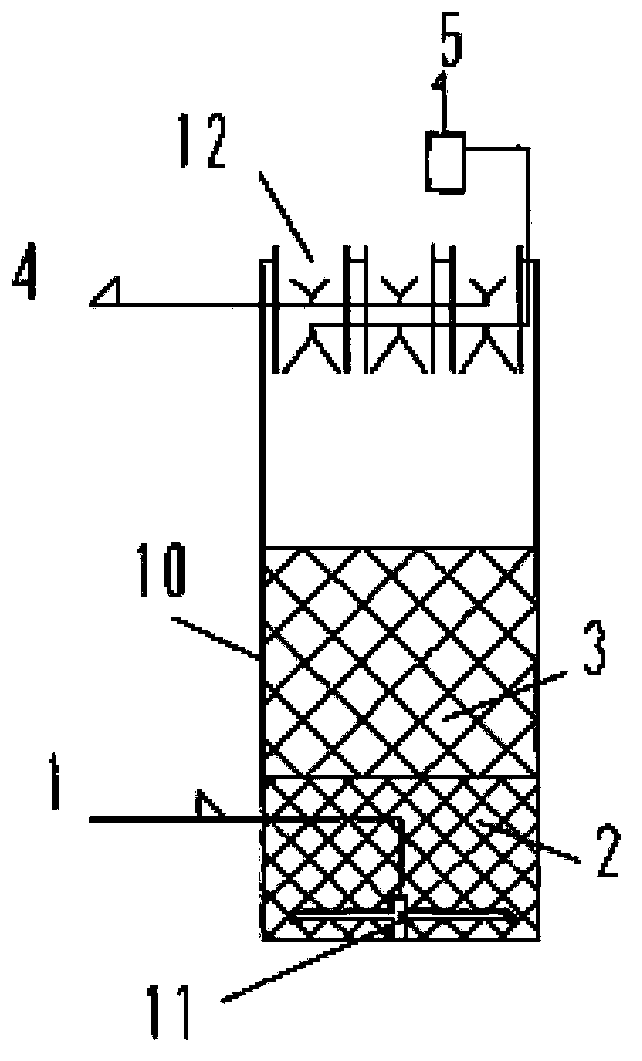

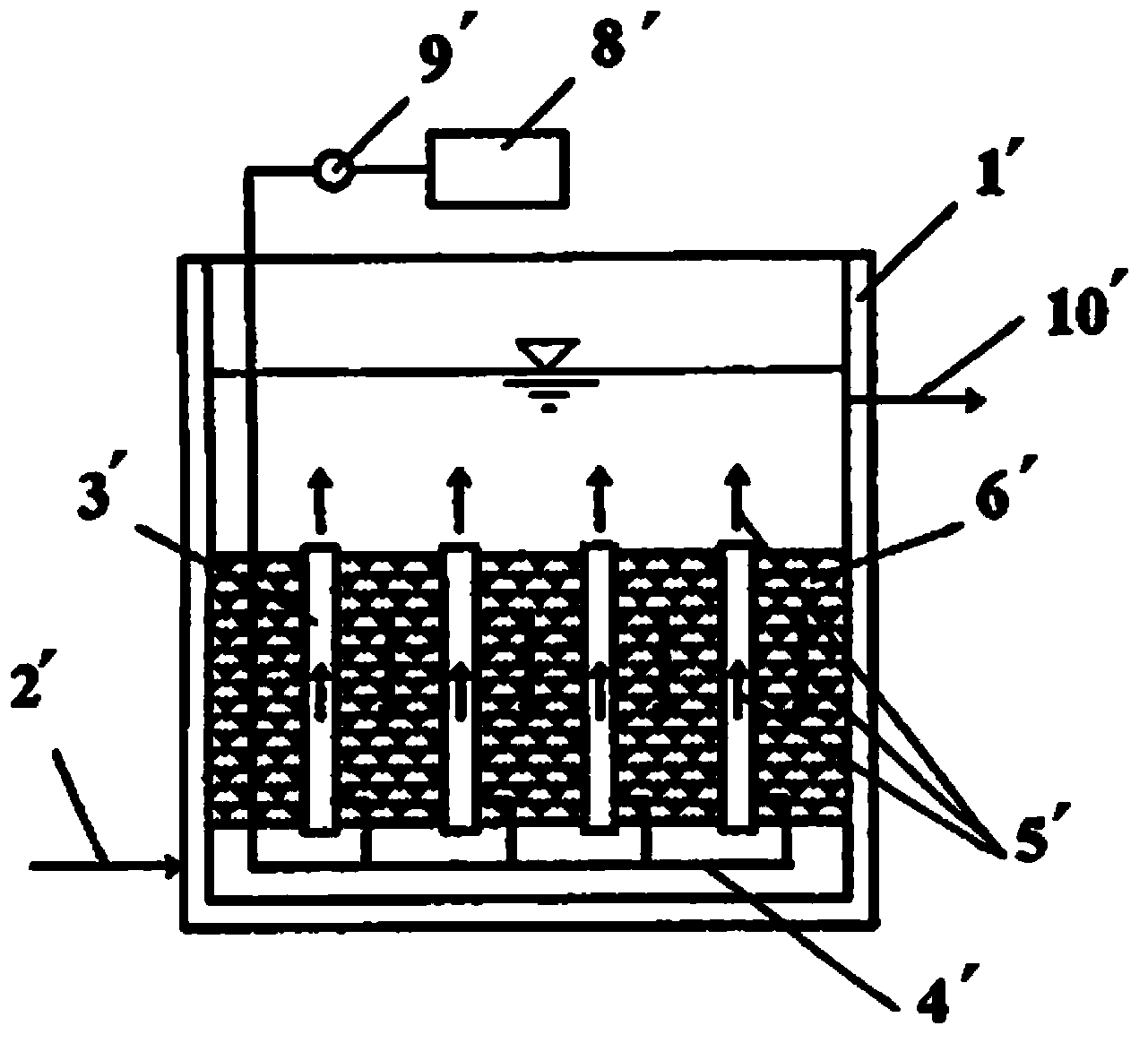

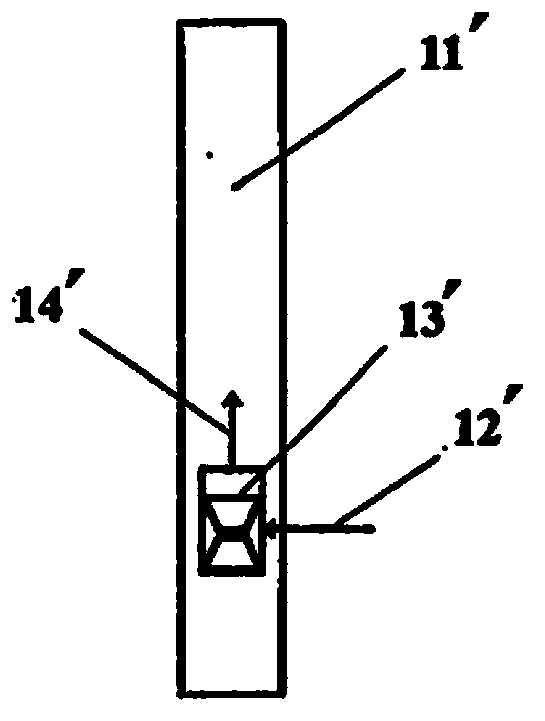

[0054] The anaerobic biological treatment in figure 1 The anaerobic sludge expanded bed reactor shown is carried out, wherein, the sludge concentration in the acidogenic bacteria accumulation area 2 and the methanogen accumulation area 3 is 30g / L; the described anaerobic sludge expanded bed reactor is high 18m and a diameter of 14m, the height of the acid-producing bacteria gathering area 2 is 4.2m, and the height of the methanogenic bacteria gathering area 3 is 8.4m. The aerobic biological treatment in figure 2 The aerobic biofilm reactor shown is carried out, wherein the sludge concentration is 5g / L.

[0055] Under the conditions of a temperature of 34°C and a pH value of 6, the coal gasification wastewater to be treated is continuously introduced from the water inlet pipe 1 of the anaerobic sludge expanded bed reactor and passed through t...

Embodiment 2

[0059] This embodiment is used to illustrate the treatment method of coal gasification wastewater provided by the present invention.

[0060] The anaerobic biological treatment in figure 1 Carry out in the shown anaerobic sludge expanded bed reactor, wherein, the sludge concentration in acidogenic bacteria accumulation area 2 and methanogen accumulation area 3 is 10g / L; Described anaerobic sludge expanded bed reactor is high The height of the acid-producing bacteria gathering area 2 is 4.8 m, and the height of the methanogenic bacteria gathering area 3 is 8.4 m. The aerobic biological treatment in figure 2 The aerobic biofilm reactor shown is carried out, wherein the sludge concentration is 4g / L.

[0061]Under the conditions of a temperature of 37°C and a pH value of 7, the coal gasification waste water to be treated is continuously introduced from the water inlet pipe 1 of the anaerobic sludge expanded bed reactor and passed through the water distributor 11 so that the for...

Embodiment 3

[0065] This embodiment is used to illustrate the treatment method of coal gasification wastewater provided by the present invention.

[0066] The anaerobic biological treatment in figure 1 In the shown anaerobic sludge expanded bed reactor, wherein, the concentration of sludge in the acidogenic bacteria accumulation area 2 and the methanogen accumulation area 3 is 50g / L; the anaerobic sludge expanded bed reactor is high The height of the acid-producing bacteria gathering area 2 is 4.8 m, and the height of the methanogenic bacteria gathering area 3 is 9.6 m. The aerobic biological treatment in figure 2 The aerobic biofilm reactor shown is carried out, wherein the sludge concentration is 3g / L.

[0067] Under the conditions of a temperature of 36°C and a pH value of 8, the coal gasification wastewater to be treated is continuously introduced from the water inlet pipe 1 of the anaerobic sludge expanded bed reactor and passed through the water distributor 11 so that the formed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com