Treatment method for coal gasification wastewater containing phenol and ammonia

A technology for coal gasification wastewater and treatment methods, applied in chemical instruments and methods, water/sewage multi-stage treatment, extraction water/sewage treatment, etc., can solve the problems of easy loss of phenol, low extraction efficiency, high pH value, etc., and achieve reduction Subsequent treatment of pollution load, reduction of extraction operation costs, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

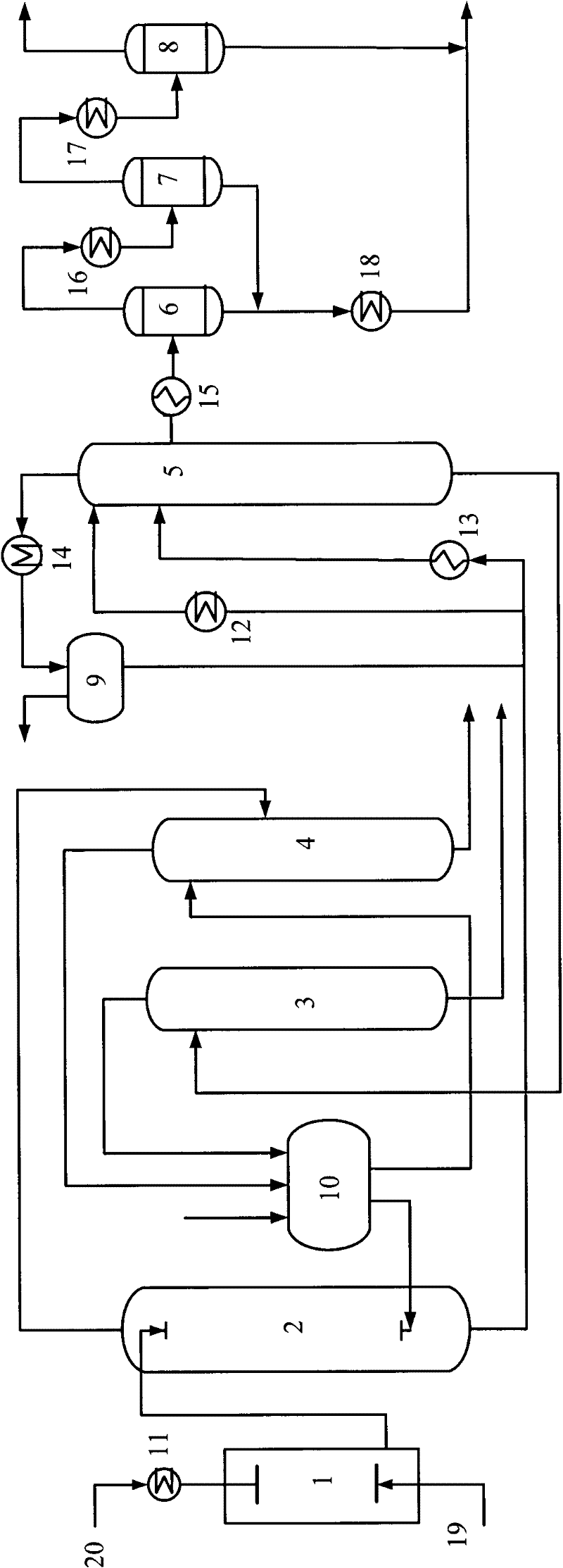

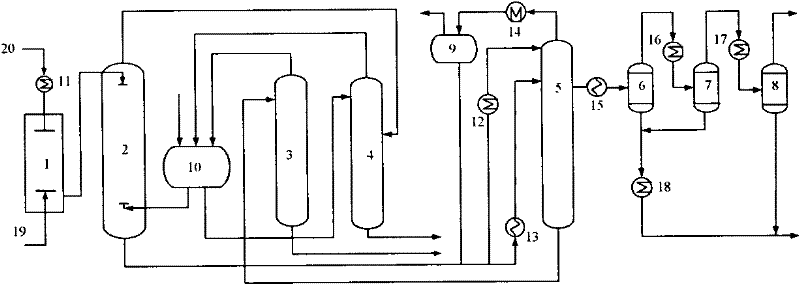

[0028] The phenol content of coal gasification sewage unit is 4000mg·L -1 , the content of polyphenols is 2000mg·L -1 , total ammonia 14.21g·L -1 , CO 2 4.18g·L -1 , the pH value is 10.1, the water temperature is 68°C, and the flow rate is 80 tons / hour. The process shown in Figure 1 is used for processing. into CO 2 The flow rate is 2800 kg / h, and the pH value is adjusted to 7.68. The extraction tower is a packed extraction tower, the extraction agent is diisopropyl ether, the extraction temperature is 39°C, and the volume ratio of solvent to sewage is 1:9. The theoretical plate of the sewage stripping tower is 57, the cold and hot feed ratio is 1:4, the temperature at the top of the tower is 45°C, the pressure at the top of the tower is 0.57MPa, the temperature at the bottom of the tower is 156°C, the pressure at the bottom of the tower is 0.61MPa, and the temperature of the side line is 140.0 °C, pressure 0.58MPa. The operating pressure of the first stage partial cond...

Embodiment 2

[0030] The phenol content of coal gasification sewage unit is 4050mg·L -1 , the content of polyphenols is 1800mg·L -1 , total ammonia 13.8g·L -1 , CO 2 4.01g·L -1 , the pH value is 9.8, the water temperature is 69°C, and the flow rate is 60 tons / hour, and the process is processed as shown in Figure 1. into CO 2 The flow rate is 2180 kg / h, and the pH value is adjusted to 7.56. The sewage stripping tower has 55 theoretical plates, the ratio of cold and hot feed is 1:4.0, the temperature at the top of the tower is 44.1°C, the pressure at the top of the tower is 0.57MPa, the temperature at the bottom of the tower is 159.7°C, the pressure at the bottom of the tower is 0.62MPa, and the temperature of the side stream is 149.0°C , pressure 0.49MPa. The operating pressure of the first stage partial condenser is 0.46MPa, the operating temperature is 144°C, the operating pressure of the second stage partial condenser is 0.36MPa, the operating temperature is 85.6°C, and the operatin...

Embodiment 3

[0032] The phenol content of coal gasification sewage unit is 3880mg·L -1 , the content of polyphenols is 1570mg·L -1 , total ammonia 16.4g·L -1 , CO 2 4.3g·L -1 ,, the pH value is 10.8, the water temperature is 68°C, the flow rate is 40 tons / hour, and the process is processed as shown in Figure 1. into CO 2 The flow rate is 1500 kg / h, and the pH value is adjusted to 7.48. Sewage stripper has 55 theoretical plates, the ratio of cold and hot feed is 1:4.0, the temperature at the top of the tower is 46.3°C, the pressure at the top of the tower is 0.55MPa, the temperature at the bottom of the tower is 158.9°C, the pressure at the bottom of the tower is 0.58MPa, and the temperature of the side stream is 143.0°C , pressure 0.47MPa. The operating pressure of the three-stage partial condenser is 0.45MPa, the operating temperature is 142°C, the operating pressure of the second partial condenser is 0.35MPa, the operating temperature is 88.2°C, and the operating pressure of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com