Anaerobic granular sludge loaded vulcanized nano zero-valent iron adsorption material as well as preparation method and application thereof

An anaerobic granular sludge and nano-zero valent iron technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of easy loss, easy aggregation, heavy metal ions and semi-metal ions Pollution and other problems, to achieve the effect of improving adsorption performance, long service life, and overcoming easy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

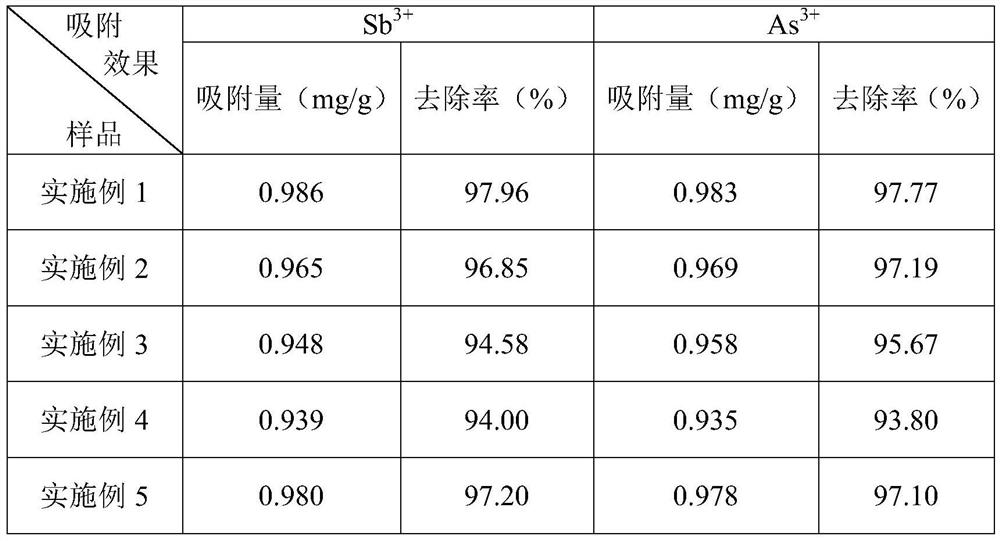

Embodiment 1

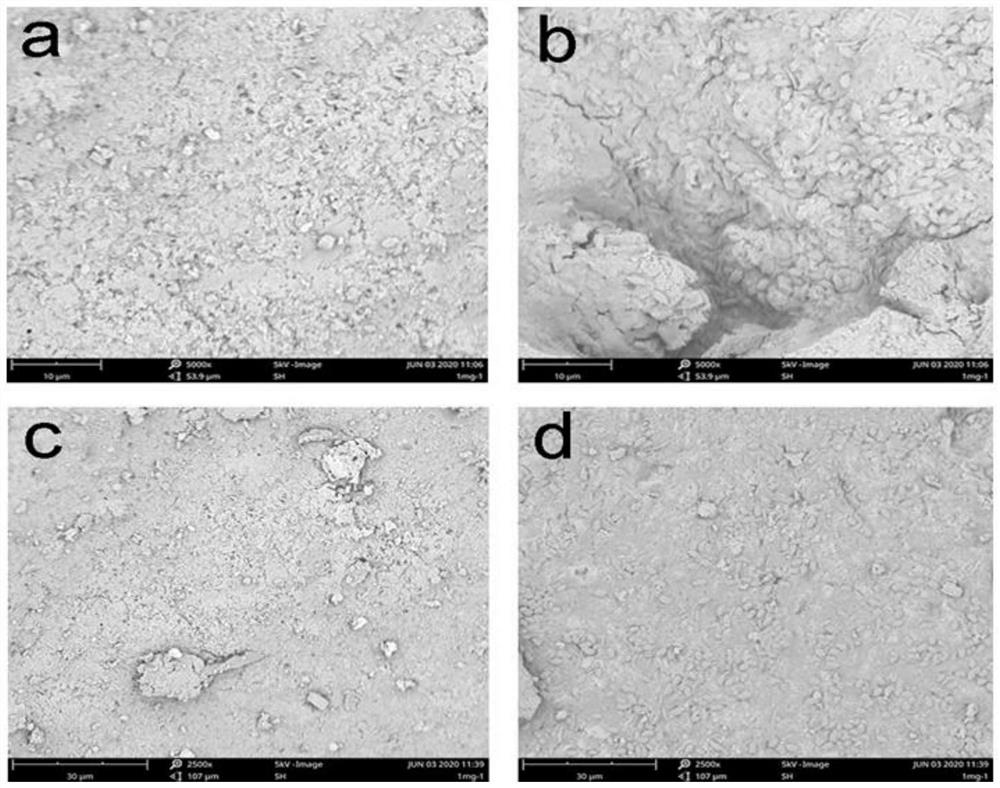

[0028] Embodiment 1 The preparation of anaerobic granular sludge loaded sulfide nanometer zero-valent iron adsorption material (carried out in the laboratory), the specific steps are as follows:

[0029] ① Pass the anaerobic granular sludge through a sieve below 80 mesh, wash and dry.

[0030] ②Put 0.75g of anaerobic granular sludge in a 500mL three-necked flask, and add 80mL of ethanol-water mixed solution (the volume ratio of ethanol to water is 1:0.25).

[0031] ③Add 15mL ferrous sulfate aqueous solution (concentration is 0.75mol / L), 94mL sodium borohydride aqueous solution (concentration is 0.75mol / L), 25mL sodium dithionite aqueous solution (concentration is 0.75mol / L) into the flask, and feed nitrogen.

[0032] ④Adopt small-scale mechanical stirring with a rotating speed of 200rpm. After stirring and reacting at room temperature for 2 hours, centrifuge at 2000rpm for 5 minutes to remove the supernatant, and then use anaerobic deionized water and oxygen-free ethanol to c...

Embodiment 2

[0034] The preparation of embodiment 2 anaerobic granular sludge loading sulfide nanometer zero-valent iron adsorption material (carried out in the laboratory), concrete steps are as follows:

[0035] ① Pass the anaerobic granular sludge through a sieve below 80 mesh, wash and dry.

[0036] ②Put 0.75g of anaerobic granular sludge in a 500mL three-necked flask, and add 80mL of ethanol-water mixed solution (the volume ratio of ethanol to water is 1:0.25).

[0037] ③Add 15mL ferrous sulfate aqueous solution (concentration is 0.5mol / L), 60mL sodium borohydride aqueous solution (concentration is 0.5mol / L), 15mL sodium dithionite aqueous solution (concentration is 0.5mol / L) into the flask, and feed nitrogen.

[0038] ④Adopt small-scale mechanical stirring with a rotating speed of 200rpm. After stirring and reacting at room temperature for 2 hours, centrifuge at 2000rpm for 5 minutes to remove the supernatant, and then use anaerobic deionized water and oxygen-free ethanol to centrif...

Embodiment 3

[0040] Embodiment 3 The preparation of anaerobic granular sludge loaded sulfide nanometer zero-valent iron adsorption material (carried out in the laboratory), the specific steps are as follows:

[0041] ① Pass the anaerobic granular sludge through a sieve below 80 mesh, wash and dry.

[0042] ②Put 0.75g of anaerobic granular sludge in a 500mL three-necked flask, and add 80mL of ethanol-water mixed solution (the volume ratio of ethanol to water is 1:0.25).

[0043] ③Add 20mL ferrous sulfate aqueous solution (concentration is 1mol / L), 80mL sodium borohydride aqueous solution (concentration is 1mol / L), 15mL sodium dithionite aqueous solution (concentration is 1mol / L) into the flask, and pass nitrogen gas.

[0044] ④Adopt small-scale mechanical stirring with a rotating speed of 200rpm. After stirring and reacting at room temperature for 2 hours, centrifuge at 2000rpm for 5 minutes to remove the supernatant, and then use anaerobic deionized water and oxygen-free ethanol to centrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com