Super-hydrophobic wear-resistant polypropylene film and preparation method thereof

A polypropylene film, super-hydrophobic technology, applied in the field of polymer materials, can solve the problems of easy loss of compatible hydrophobic agents and wear-resistant agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 4-cyano-4-(thiobenzoyl)valeric acid (5.0mmol) was added to the 50ml side-neck flask equipped with a stirring bar, 20ml anhydrous tetrahydrofuran THF was added with a syringe, and chlorination was slowly added dropwise under constant stirring. Sulfoxide SOCl 2 (50.0 mmol), the temperature of the oil bath was raised to 75°C, refluxed for 2.5 h, and the SOCl was distilled off under reduced pressure after the reaction was completed. 2 and THF to obtain a yellow oily product, which was dissolved in an appropriate amount of toluene solution.

[0035] Add single-end hydroxy polypropylene PP-OH (0.8 mmol) into a 100 mL branch-neck flask equipped with a stirrer, and after filling with nitrogen three times, under N 2 Under the atmosphere, add 30ml of anhydrous toluene, under constant stirring, slowly heat the oil bath temperature to 70°C, after the polymer is completely dissolved, add 1.5ml of pyridine, and slowly add the above yellow dissolved in toluene solution after 40min. ...

Embodiment 2

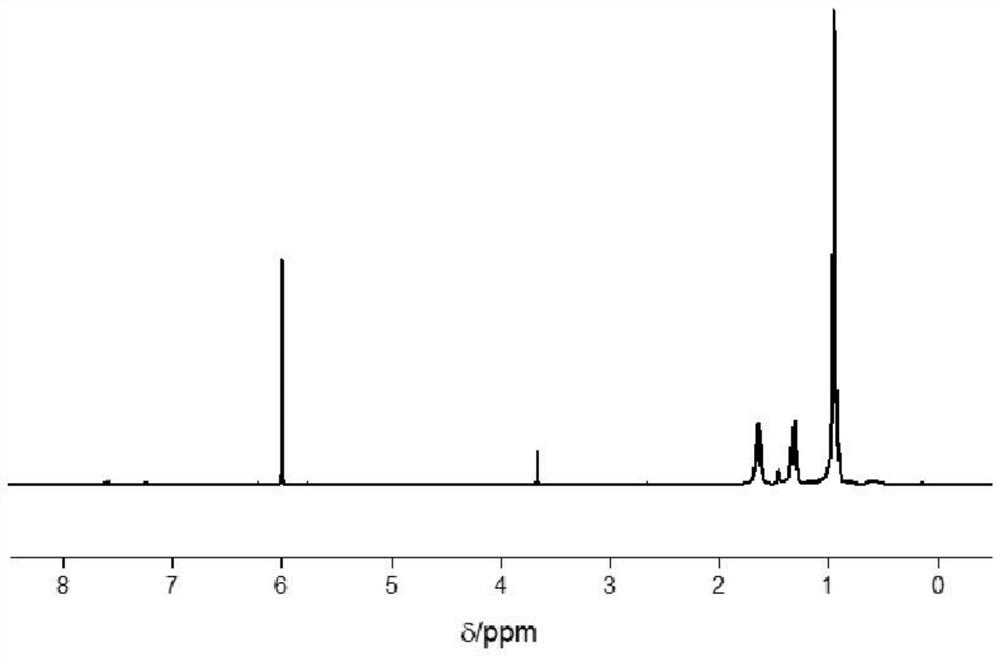

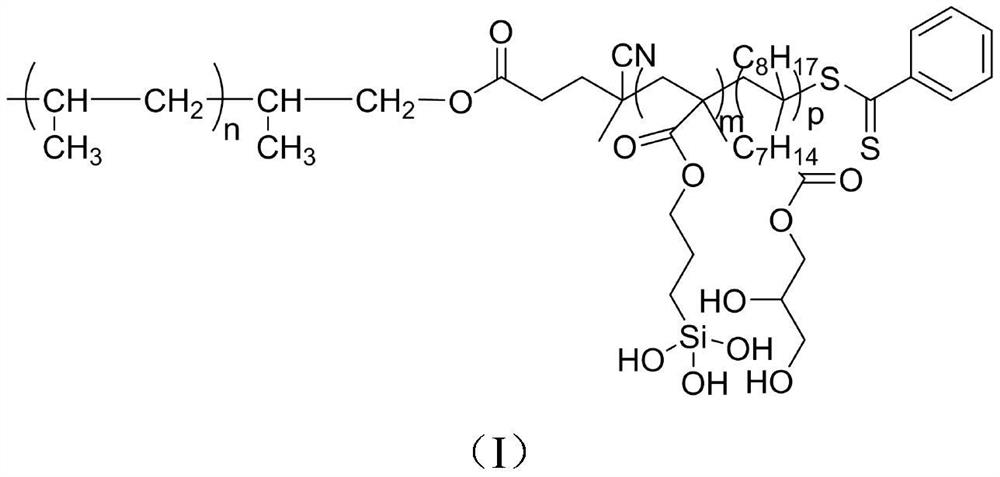

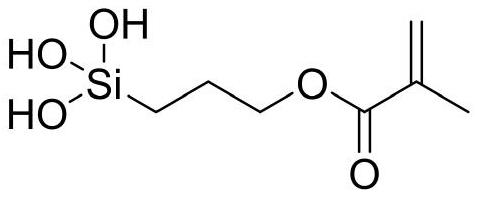

[0037] The polypropylene macromolecular chain transfer agent (0.1 mmol), silane coupling agent (10 mmol), AIBN (0.01 mmol) and 5 mL of dioxane prepared in Example 1 were added to a 10-ml Schlenk bottle with a stirring bar. , set the temperature of the oil bath to 75°C, and after three cycles of liquid nitrogen freezing-pumping-thawing, place the Schlenk bottle in the oil bath reaction pot for polymerization reaction, and immediately take out the Schlenk bottle and put it in liquid nitrogen after 3 hours of reaction. After cooling, the crude product was repeatedly precipitated in anhydrous ether, and the precipitate was filtered and vacuum-dried to obtain a superhydrophobic polypropylene block copolymer with a yield of 72.8%.

Embodiment 3

[0039] The superhydrophobic polypropylene block copolymer (0.1 mmol), anti-wear agent (10 mmol), AIBN (0.01 mmol) and 5 mL of dioxane prepared in Example 2 were respectively added to a 10-ml Schlenk bottle with a stirring bar. , set the temperature of the oil bath to 75°C, and after three cycles of liquid nitrogen freezing-pumping-thawing, place the Schlenk bottle in the oil bath reaction pot for polymerization reaction, and immediately take out the Schlenk bottle and put it in liquid nitrogen after 3 hours of reaction. After cooling, the crude product was repeatedly precipitated in anhydrous ether, and the precipitate was filtered and vacuum-dried to obtain a superhydrophobic wear-resistant polypropylene block copolymer with a yield of 67.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com