Advanced treatment method for Lurgi coal gasification wastewater

An advanced treatment and coal-to-gas technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high cost and unreachable discharge of Lurgi furnace coal-to-gas wastewater Standards and other issues to achieve the effect of developed voids, increasing the concentration of available carbon sources and nitrogen sources, and reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

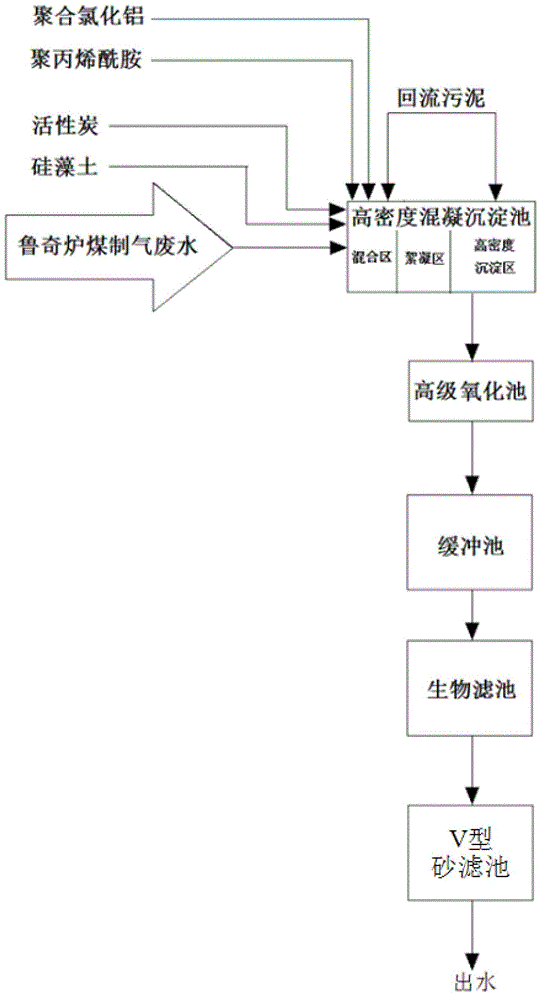

[0013] Specific implementation mode one: this implementation mode is a kind of advanced treatment method of Lurgi furnace coal gasification waste water, specifically completes according to the following steps:

[0014] 1. Coagulation and adsorption treatment: firstly, the Lurgi furnace coal gasification wastewater is passed into the coagulation sedimentation tank, and then polyaluminum chloride, polyacrylamide, diatomite and powdered activated carbon are added, and the sludge reflux ratio is 50% ~100% and the stirring speed is 50r / s~70r / s under the condition of stirring for 4min~6min, and then under the condition of the sludge reflux ratio of 50%~100% and the stirring speed of 0.2r / s~0.5r / s The flocculation is 25min~35min; the dosage of polyaluminum chloride mentioned in step 1 is 80mg / L~100mg / L; the dosage of polyacrylamide mentioned in step 1 is 20mg / L~30mg / L ; The dosage of diatomite described in step 1 is 180mg / L~200mg / L; The dosage of powdered activated carbon described i...

specific Embodiment approach 2

[0024] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the concentration of CODcr in the Lurgi furnace coal gasification wastewater described in step 1 is 150mg / L~250mg / L, NH 4 -N concentration is 40mg / L~80mg / L, phenol concentration is 10mg / L~20mg / L, quinoline concentration is 45mg / L~55mg / L, pyridine concentration is 3mg / L~4mg / L, no cyanide . Others are the same as the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the dosage of polyaluminum chloride described in step 1 is 90 mg / L. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com