Coal gasification wastewater treatment device and treatment method thereof

A technology of coal gasification wastewater and treatment device, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of long hydraulic retention time, long reaction process and high treatment cost , to achieve the effect of short hydraulic retention time, high biological activity and high denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

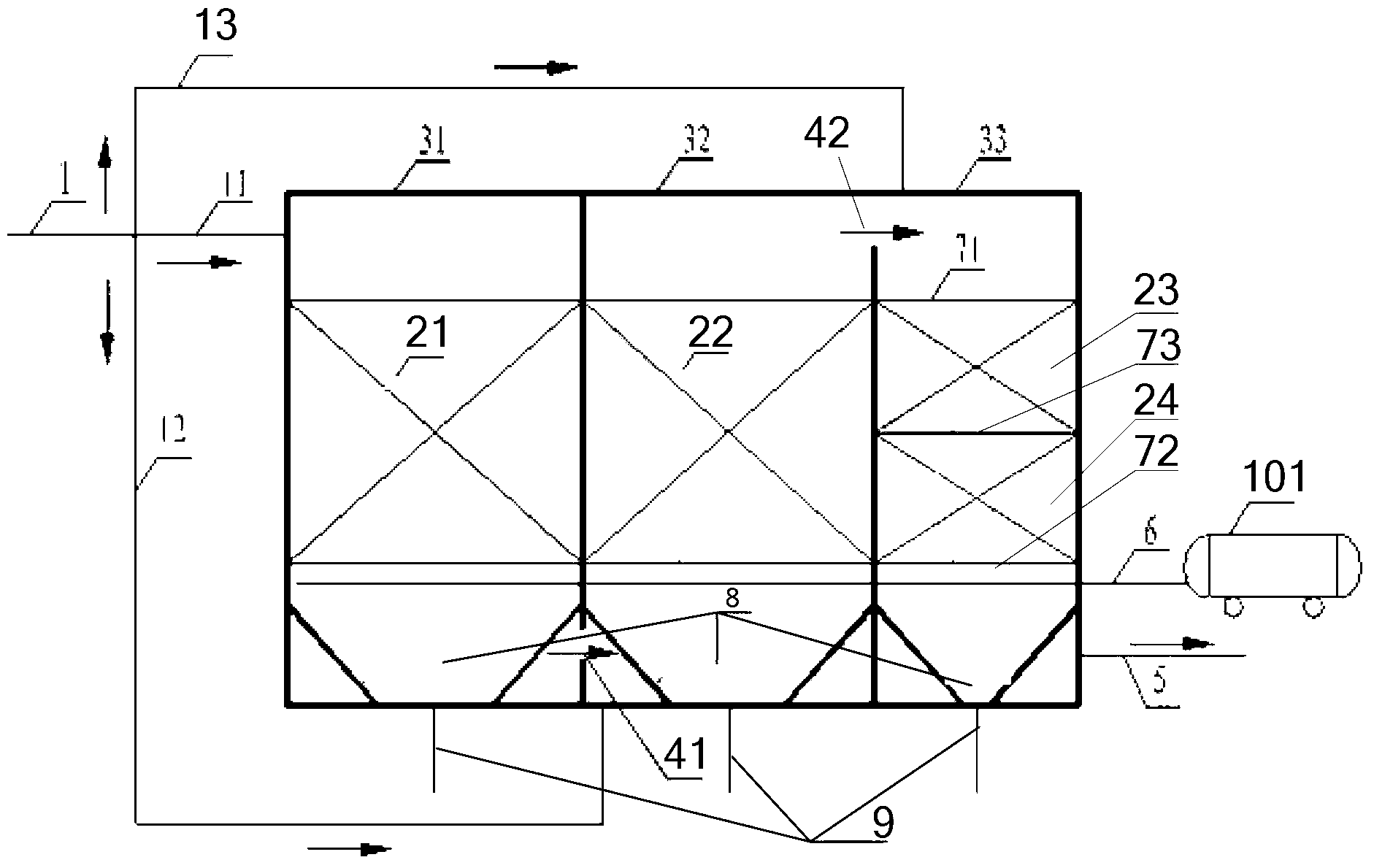

[0050] The volume of the first biological oxidation tank 31 is equal to that of the second biological oxidation tank 32, and the volume of the third biological oxidation tank 33 accounts for 25% of the total volume of the device;

[0051] The first carrier 21, the second carrier 22 and the third carrier 23 are polyurethane porous cubes, the average side length of the first carrier 21 and the second carrier 22 is 30mm, and the average aperture range is 1~4mm, and the side length of the third carrier 23 is 20mm, the aperture range is 1-2mm, the side length of the fourth carrier 24 is 40mm, and the aperture is 4-7mm;

[0052] In the specific implementation process, the coal gasification wastewater is first pretreated by the regulating tank and the physical and chemical sedimentation tank to remove part of the suspended solids, and then divided into three parts by the main water inlet, and enters the first water inlet 11 and the second water inlet simultaneously in proportion. 12 ...

Embodiment 2

[0063] The volume of the first biological oxidation tank 31 is equal to that of the second biological oxidation tank 32, the volume of the third biological oxidation tank 33 accounts for 20% of the total volume of the device, and the dissolved oxygen concentration control device includes an aeration pipe 6 and a centrifugal fan;

[0064] The first carrier 21, the second carrier 22 and the third carrier 23 are polyurethane porous cubes, the average side length of the first carrier 21 and the second carrier 22 is 30mm, and the average aperture range is 1~4mm, and the side length of the third carrier 23 is 20mm, the aperture range is 1-2mm, the side length of the fourth carrier 24 is 40mm, and the aperture is 4-7mm;

[0065] In the specific implementation process, the coal gasification wastewater is first pretreated by the regulating tank and the physical and chemical sedimentation tank to remove part of the suspended solids, and then divided into three parts by the main water inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com