Advanced treatment process for coal gasification wastewater

A coal gasification wastewater and advanced treatment technology, applied in the direction of oxidized water/sewage treatment, water/sewage multi-stage treatment, neutralized water/sewage treatment, etc., can solve high investment cost and operation cost, pipeline blockage, and influence on catalytic oxidation tower processing effect and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

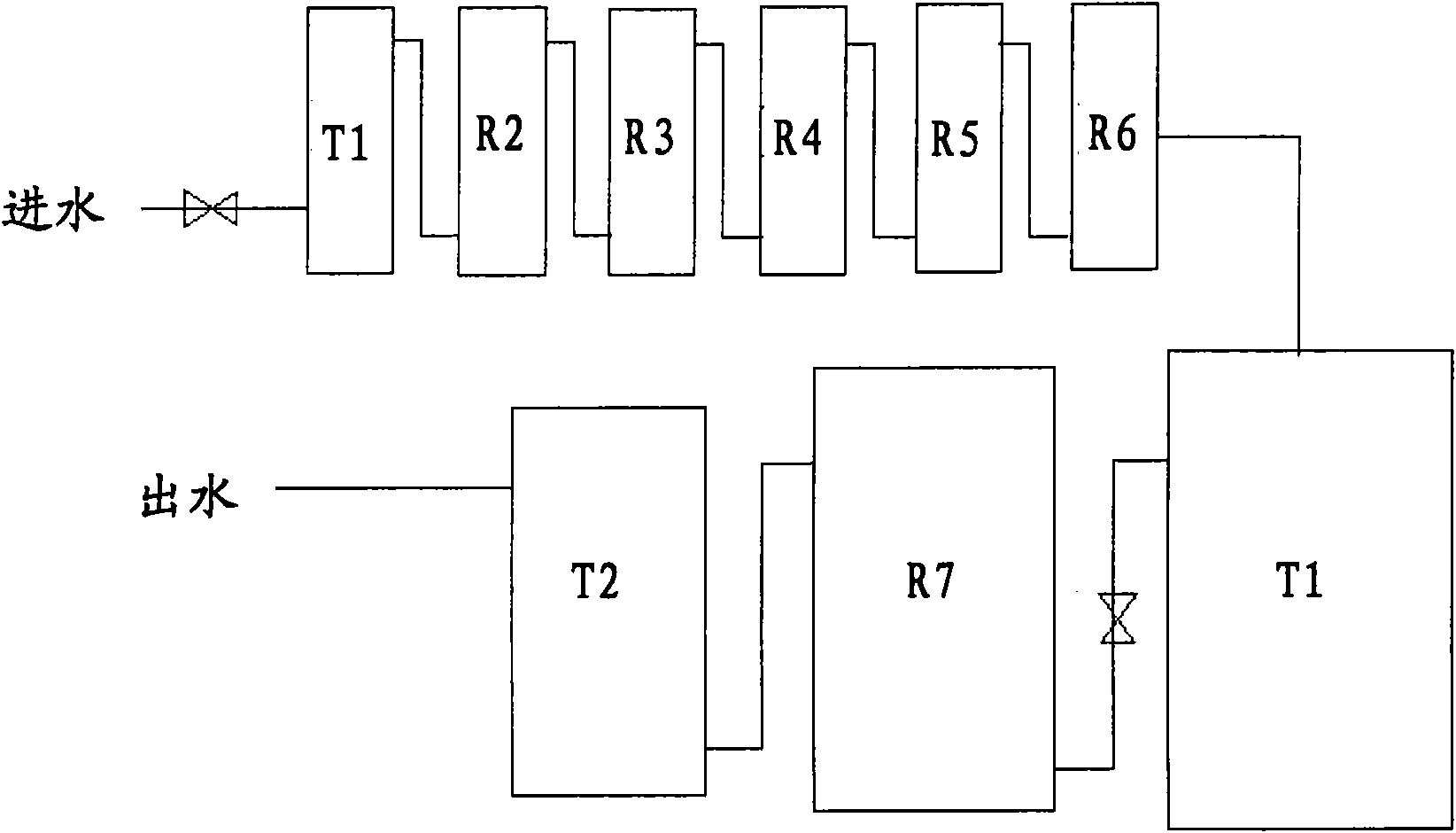

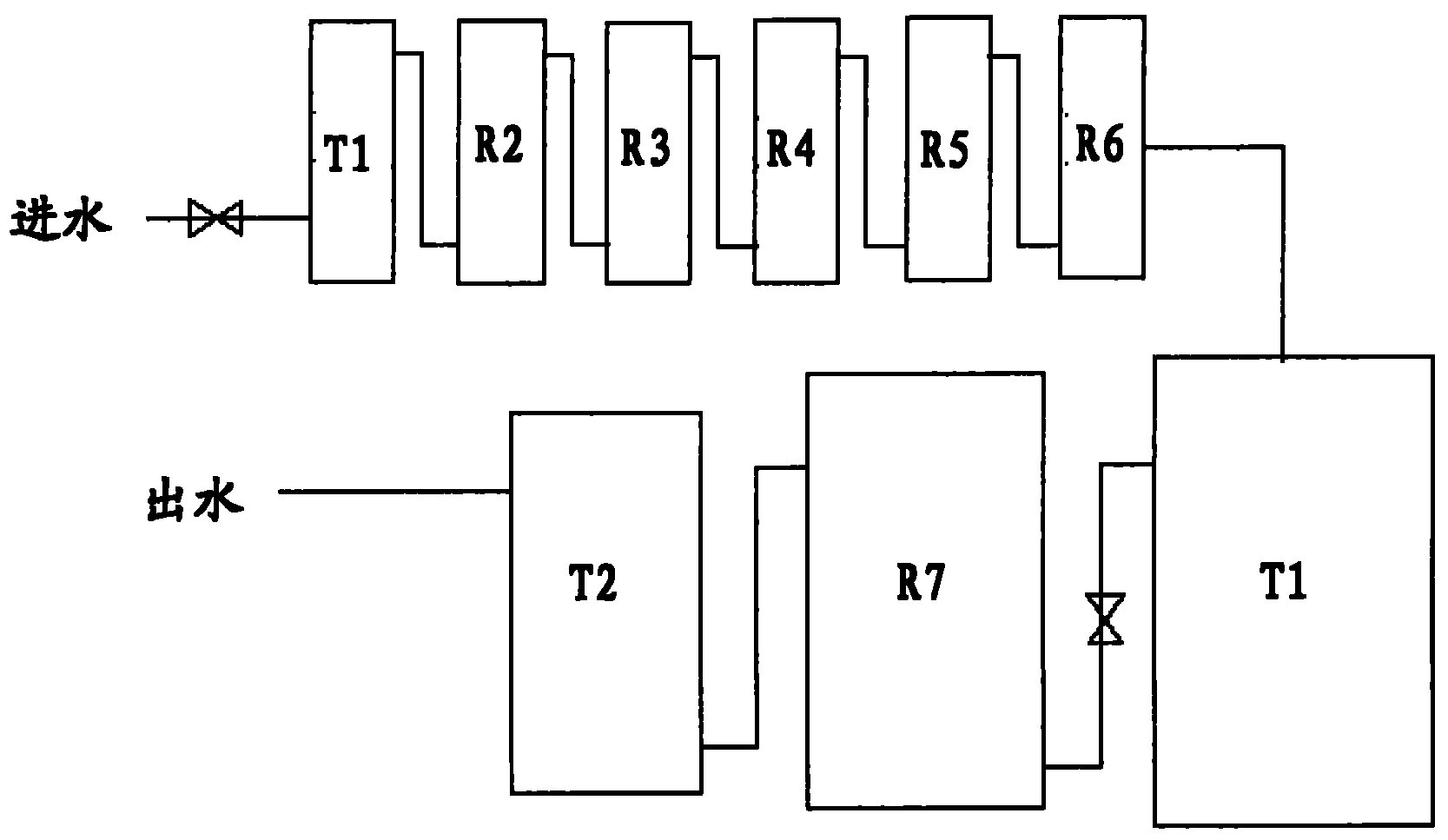

[0036] The process schematic diagram of this embodiment is as figure 1 shown. A company's coal gasification wastewater has a COD of about 450mg / L and a chroma of about 1000 after biological treatment. It is planned to use the advanced treatment method of the present invention for treatment. Each container R1-R7 is made of plexiglass. Among them, the volume of R1-R6 is 1.5L, cylindrical, with a stirring paddle in the middle. Wherein vessels R1 , R2 and R4 act only as vessels; whereas vessel R3 also acts as a reactor in which the Fenton oxidation takes place; vessels R5 and R6 also act as coagulators. The wastewater to be advanced treatment enters R1 from a pump (not shown), and flows into subsequent containers in sequence. R1-R6 are connected to automatic dosing peristaltic pumps, and the amount of medicine added is controlled by adjusting the speed of the pump. Precipitator T1 has a volume of 10L and is square. The volume of the catalytic oxidation reactor R7 is 5L, cylind...

Embodiment 2

[0040] The wastewater to be advanced treatment and the technological process used and each equipment are all the same as in Example 1, but the process parameters are changed: FeSO is added in the Fenton oxidation 4 ·7H 2 The amount of O is 600mg / L, H 2 o 2 The amount of water is 800mg / L, the aeration rate of R7 is 8 cubic meters of air per hour per cubic meter of reactor volume, and the hydraulic retention time of wastewater in R7 is 1.5h. , other parameters are the same as in Example 1. After 90 days of continuous operation, the COD values of T1 and T2 effluent ranged from 220-240mg / L and 40-90mg / L respectively, and the chromaticity of T2 effluent was less than 50.

Embodiment 3

[0042] The equipment and process flow used in this example are the same as in Example 1, but the wastewater to be advanced treatment and some process parameters are different. In this embodiment, the aggregated coal gasification wastewater of a certain factory is treated, its COD is about 1000 mg / L, and its chroma is about 1200. Add FeSO only in Fenton oxidation in process parameters 4 ·7H 2 The amount of O is 2000mg / L, H 2 o 2 The amount of water is 2800mg / L, the aeration rate of R7 is 8 cubic meters of air per hour per cubic meter of reactor volume, and the hydraulic retention time of wastewater in R7 is 1.5h. , other parameters are the same as in Example 1. After 90 days of continuous operation, the COD values of T1 and T2 effluent ranged from 240-260mg / L and 40-80mg / L respectively, and the chromaticity of T2 effluent was less than 50.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com