Coal gasification wastewater treating and recycling method and device

A coal gasification waste water, gas water technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as difficult to meet discharge standards, and achieve a small footprint of the device , large processing capacity, and the effect of process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

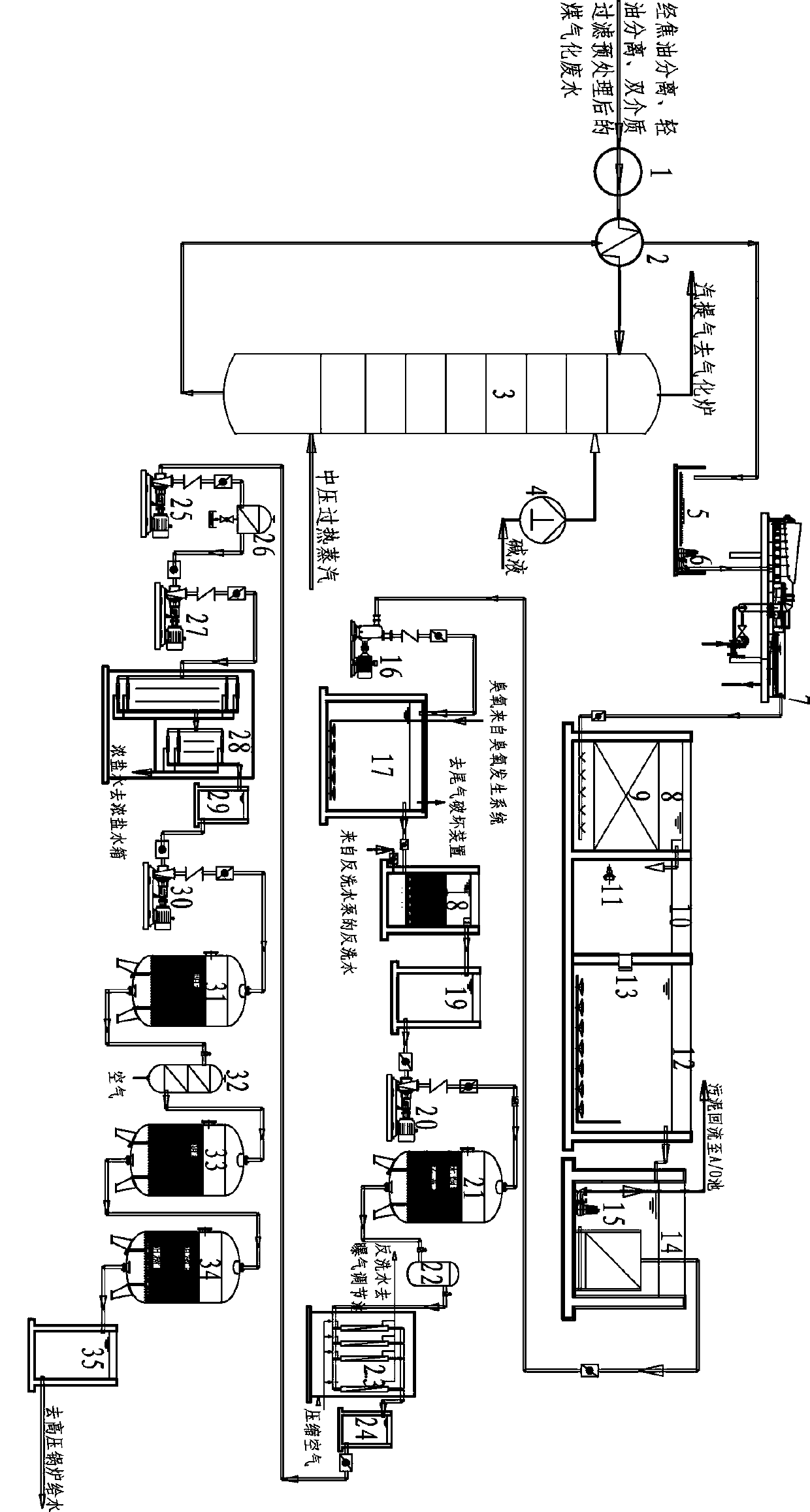

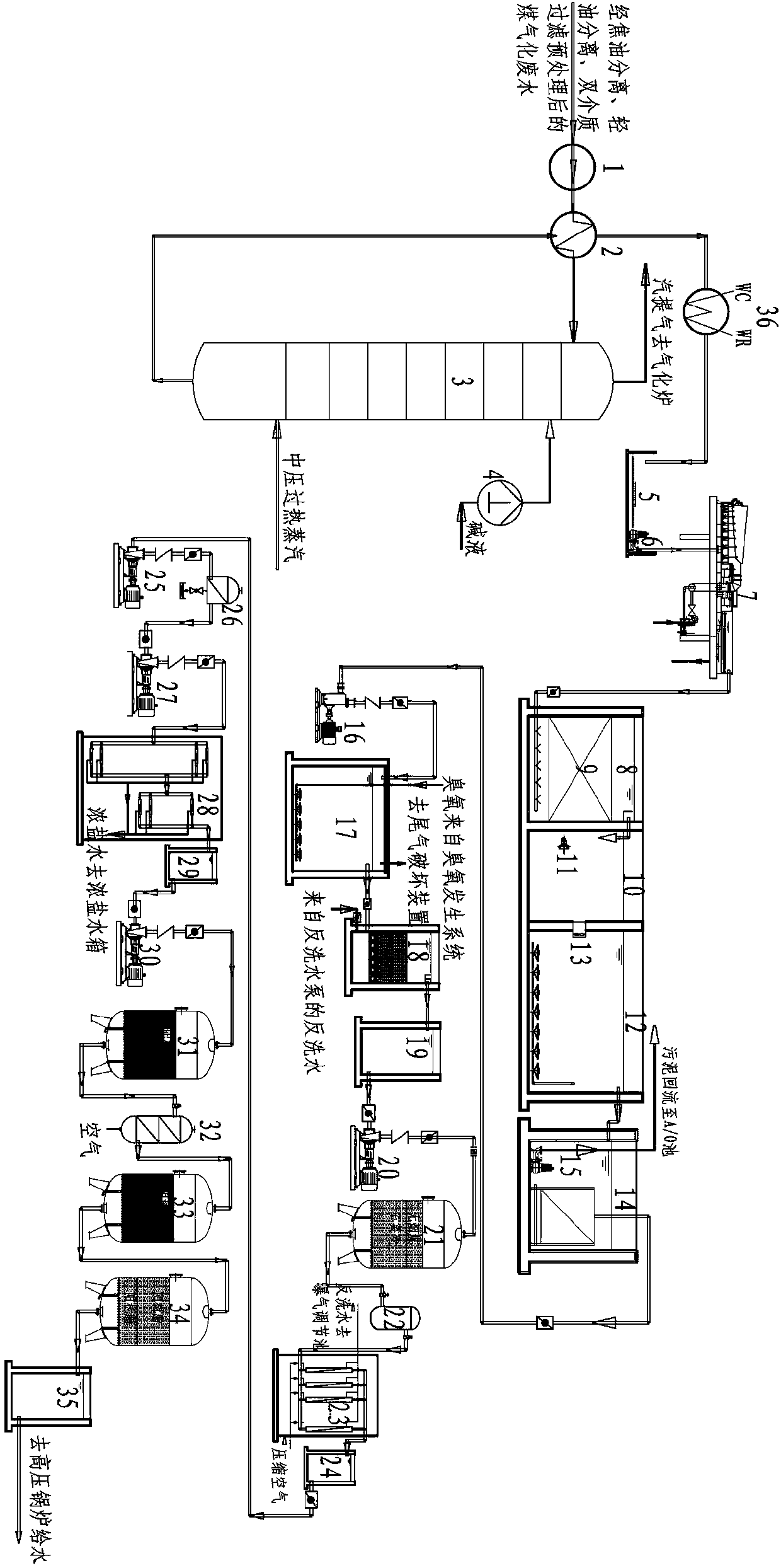

[0050] For further disclosing the technological route of the present invention, below in conjunction with description figure 2 Describe the process route in detail.

[0051] After the coal gasification wastewater transported from the coal pressurized gasification device is pretreated by tar separation, light oil separation, and double-media filtration, the high-pressure gas water pump 1 is used for medium-pressure stripping, and then the gas water is transported to the heat exchanger 2 Carry out preheating, the gas water after the preheating enters stripping tower 3 and carries out medium-pressure stripping, and medium-pressure superheated steam directly leads to the bottom of stripping tower, and 20% lye is sent to the bottom of stripping tower by lye metering pump 4 Feed line, stripping out CO 2 、H 2 S, NH 3 and trace inert gas and other volatile substances, the saturated steam after stripping is sent to the gasifier for reuse as a gasification agent, and the high-temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com