Treatment or recycling method and purpose for coal gasification and coal carbonization waste water

A technology of coking wastewater and coal gasification, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem that COD and ammonia nitrogen cannot meet the national discharge standards, and the effluent is difficult to meet Issues such as secondary emission standards and difficulty in meeting emission requirements at the same time achieve the effects of reducing the load of the treatment process, reducing the difficulty of operation, and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

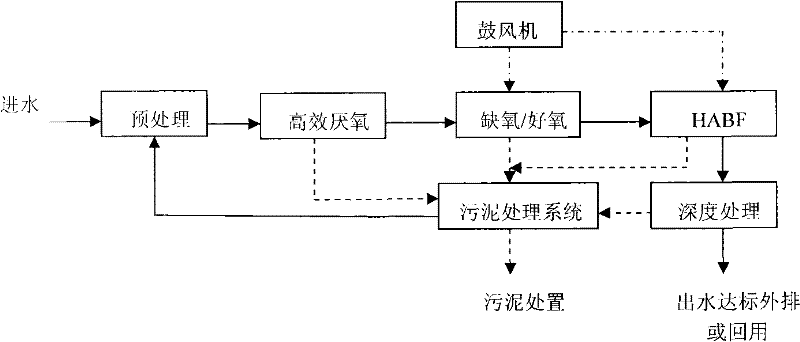

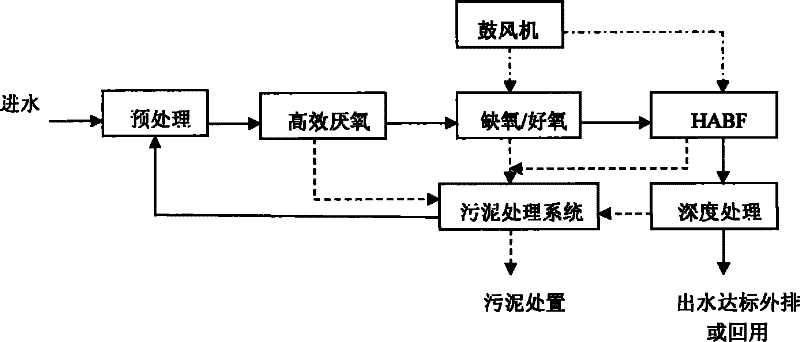

Method used

Image

Examples

Embodiment 1

[0025] Using the above combined process to treat the influent COD and NH after coagulation and sedimentation pretreatment 3-N is about 2865mg / L and 127mg / L respectively, the actual coal gasification wastewater is treated in a small test experiment, the experimental water flow rate is 100mL / h, the effective volume of the anoxic biofilter and the secondary aerobic biofilter reactor The hydraulic retention time of the anoxic biofilter reactor is 20h, and the hydraulic retention time of the secondary aerobic biofilter reactor is 40h. The carrier loading in the reactor is 60%, and the volume of a single carrier is 20mm×20mm×20mm. The density is 0.9g / cm 3 , the water holding capacity is 2500%, the dissolved oxygen concentration in the aerobic reactor is controlled at 4-6mg / L, and sufficient alkalinity is added, the activated sludge of the coking wastewater treatment plant is inoculated in the biofilter reactor, and engineering bacteria are added B350M conducts biological enhancemen...

Embodiment 2

[0027] A coking branch of an iron and steel group produced 10848m of comprehensive wastewater 3 / d(452m 3 / h), using the above combination process to process it. After the comprehensive wastewater is collected in the regulating tank, it is pumped to the oil separation and air flotation process to remove most of the oil and SS in the wastewater. The pretreated wastewater is treated in the anaerobic pool and then enters the anoxic pool and aerobic pool at the back end for further treatment. Treatment, the effluent from the aerobic tank enters the high-efficiency biological aerated filter for advanced treatment and then enters the double-membrane treatment system. The membrane effluent after desalination is reused as process circulating cooling water, and the pre-membrane concentrate is used for blast furnace slag flushing.

[0028] The above combined process is used to treat the comprehensive discharge wastewater of coal coking, and the design water volume is 10848m3 3 / d(452m...

Embodiment 3

[0030] A coking group produced 1680m of comprehensive wastewater 3 / d(70m 3 / h), using the above combination process to process it. After the comprehensive wastewater is collected by the regulating tank, it is pumped to the oil separation and air flotation process to remove most of the oil and SS in the wastewater. The pretreated wastewater is treated by the high-efficiency anaerobic pool and then enters the anoxic pool and the aerobic pool at the back end For treatment, the effluent from the aerobic tank enters the high-efficiency aerated biological filter for advanced treatment and then enters the double-membrane treatment system. The membrane effluent after desalination is reused as process circulating cooling water, and the pre-membrane concentrate is used for coal washing in coal yards or after further treatment Discharge.

[0031] The combined process above is used to treat coal coking comprehensive discharge wastewater, and the design water volume is 1680m 3 / d(70m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com