Coal gasification wastewater processing method

A technology of coal gasification wastewater and treatment methods, applied in chemical instruments and methods, water/sewage multi-stage treatment, flotation water/sewage treatment, etc., can solve the problems of organic pollutants and ammonia nitrogen, unreachable chroma, hydraulic retention Long time and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

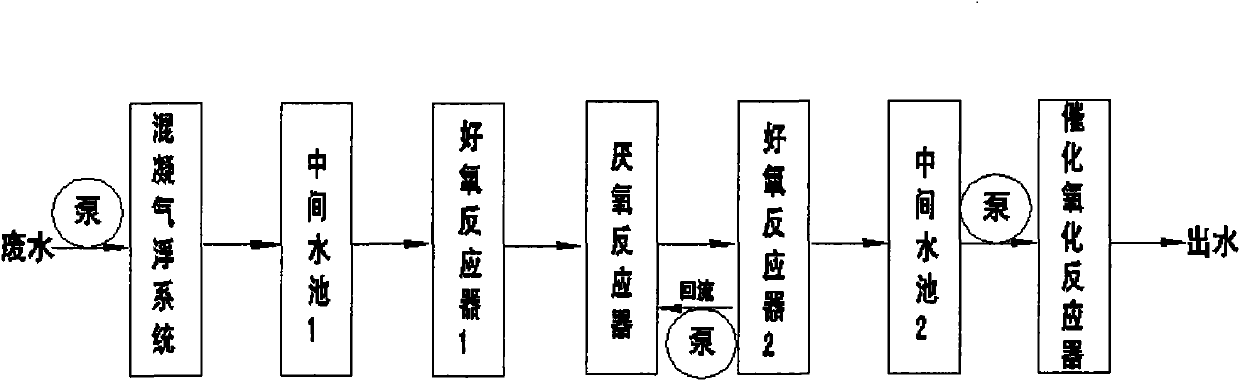

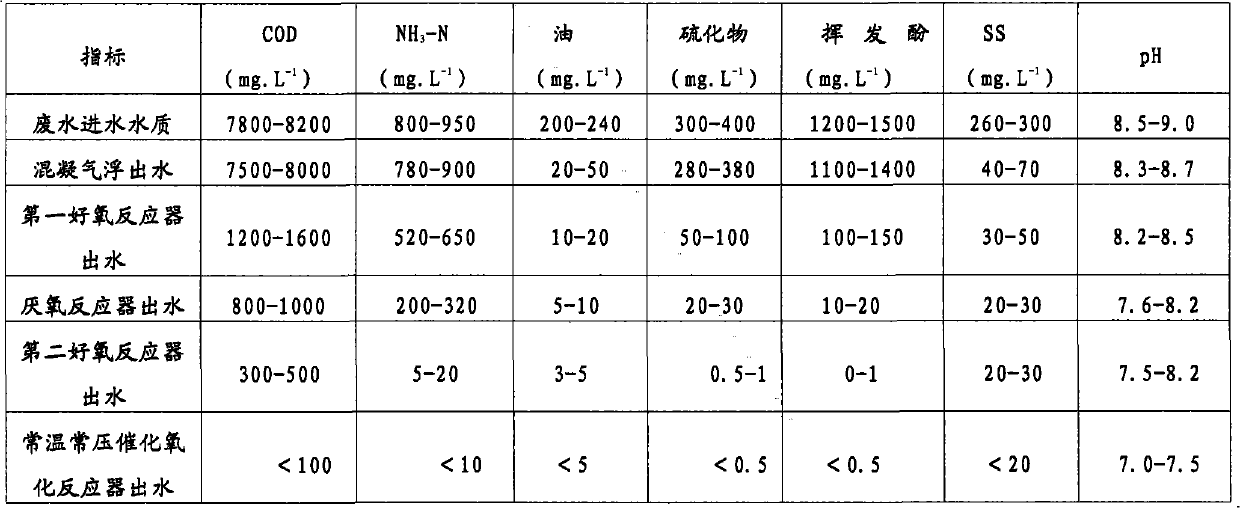

[0044] The high-concentration coal gasification wastewater of a company is treated with the process shown in the attached figure. The quality of the wastewater is shown in Table 1-1. The wastewater treatment capacity of the process system is 2 tons / day, of which the coagulation air flotation system is a customized pressurized dissolved air coagulation air flotation machine, the first aerobic reactor, anaerobic reactor, and the second aerobic reactor And the intermediate pool is all made of carbon steel, and 50% of the biological filler described herein is filled in each reactor. The normal temperature and pressure catalytic oxidation reactor is made of plexiglass, with ozone as the oxidant, filled with 75% of the Catalyst, described catalyzer is load-type catalyst, and its carrier is granular coconut shell activated carbon, and active component is the composite oxide that is made up of oxide of iron, copper oxide and zinc oxide, and wherein respectively with Fe 2 o 3 , CuO an...

Embodiment 2

[0048] The comprehensive wastewater of a coal gasification company is treated with the process shown in the attached figure, and the quality of the wastewater is shown in Table 2-1. The reactor, equipment and biological filler adopted in this embodiment are the same as in Example 1, the waste water treatment capacity is 3 tons / day, the addition of PAC and PAM is 100-120mg / L and 1-3mg / L, K 2 HPO 4 The addition amount of the wastewater is 20-50mg / L, the HRT of the waste water in the first aerobic reactor, anaerobic reactor and the second aerobic reactor is 16h, 13.5h and 13.5h respectively, and in the ozone catalytic oxidation reactor The HRT is 1-1.5h, the amount of ozone added is 8-10mg / L, the catalyst is a supported catalyst, and the granular coal-based activated carbon is used as the carrier. The active components are iron oxides, copper oxides and manganese. A composite oxide composed of oxides, and in which Fe 2 o 3 , CuO and MnO 2 The mass sum of the above three oxide...

Embodiment 3

[0052] Using the process shown in the accompanying drawings, the difference compared with Example 1 is that a Fenton oxidation reactor made of carbon steel is added before the catalytic oxidation reactor. The combined process of coagulation air flotation, OAO, Fenton oxidation, and normal temperature and pressure catalytic oxidation is used sequentially to treat the high-concentration coal gasification wastewater in Example 1. The reactor, equipment and biological filler used in this example are the same as those in Example 1. , The wastewater treatment capacity is 2 tons / day. Sequential addition of FeSO to the feed water line of the Fenton oxidation reactor 4 and H 2 o 2 , the addition amount is respectively 950-1100mg / L and 1400-1600mg / L, and the catalytic oxidation reaction uses air as an oxidant, and fills 70% of the catalyst, and the catalyst is a granular coconut shell activated carbon as a carrier, and the active component is A composite oxide composed of iron oxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com